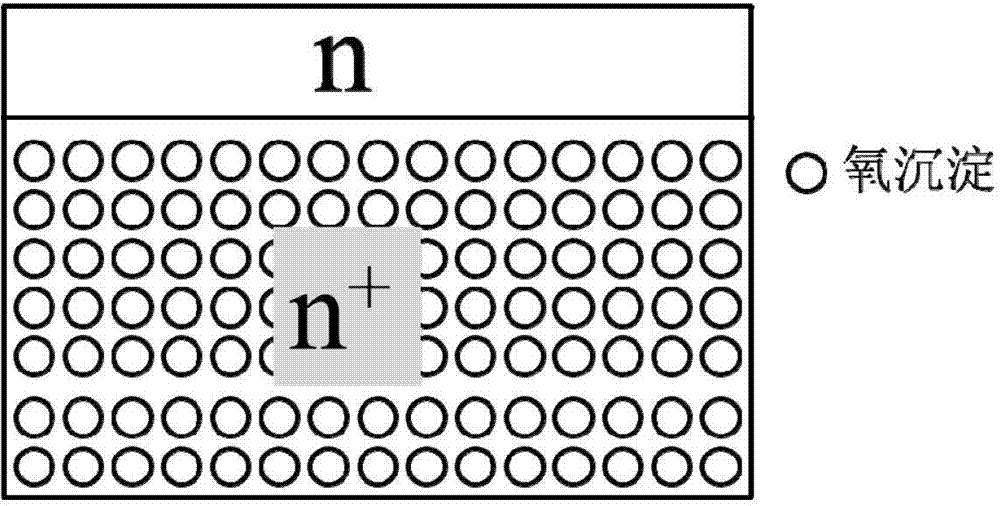

N/n+ silicon epitaxial wafer with high metal impurity absorption capacity and preparation method thereof

A silicon epitaxial wafer, high-metal technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as the inability to meet metal gettering, and achieve the goal of promoting metal gettering efficiency, excellent quality, and reducing power consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

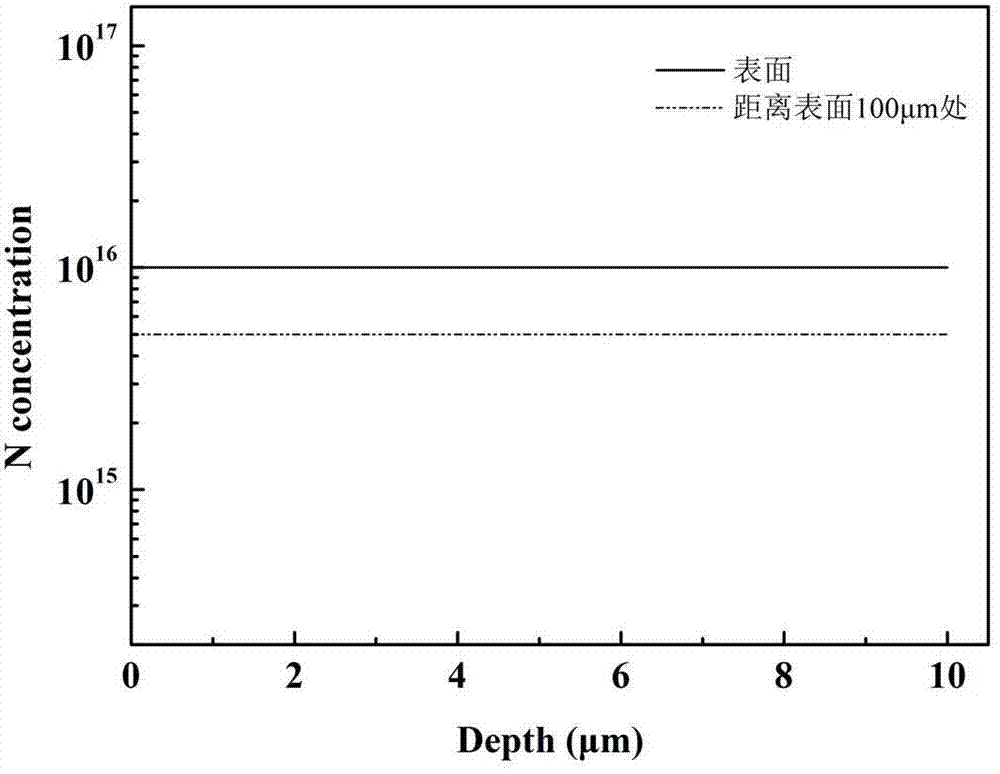

[0056] Production of n / n with high metal gettering ability based on heavily arsenic-doped Czochralski silicon + A method for preparing a silicon epitaxial wafer, comprising the following steps:

[0057] 1) Select heavily arsenic-doped Czochralski silicon with a diameter of 200mm in the crystal direction as n / n + The substrate of the silicon epitaxial wafer, the substrate resistivity is 0.003~0.005Ω·cm, and the oxygen concentration is 1.02×10 18 / cm 3 ;

[0058] 2) After the heavily arsenic-doped Czochralski silicon was cleaned by RCA, it was placed in high-purity N 2 Heat treatment at 1260°C for 60s in a rapid heat treatment furnace under atmosphere, and rapidly cool at a cooling rate of 50°C / s to obtain a nitrogen-doped heavily arsenic-doped Czochralski silicon substrate;

[0059] 3) Place the nitrogen-doped heavily arsenic-doped Czochralski silicon substrate in an epitaxy furnace, and grow a lightly phosphorous-doped silicon epitaxial layer with a thickness of 60 μm and...

Embodiment 2

[0102] Production of n / n with high metal gettering ability based on heavy antimony doped Czochralski silicon + A method for preparing a silicon epitaxial wafer, comprising the following steps:

[0103] 1) Select heavily antimony-doped Czochralski silicon with a diameter of 200mm in the crystal orientation as n / n + The substrate of the silicon epitaxial wafer, the substrate resistivity is 0.001~0.003Ω·cm, and the oxygen concentration is 7×10 17 / cm 3 ;

[0104] 2) After the heavily arsenic-doped Czochralski silicon was cleaned by RCA, it was placed in high-purity N 2 Heat treatment at 1200°C for 40s in a rapid heat treatment furnace under atmosphere, and rapidly cool at a cooling rate of 100°C / s to obtain a nitrogen-doped heavily antimony-doped Czochralski silicon substrate;

[0105] 3) Place the nitrogen-doped heavily antimony-doped Czochralski silicon substrate in an epitaxial furnace, and grow a lightly phosphorus-doped silicon epitaxial layer with a thickness of 20 μm ...

Embodiment 3

[0115] Production of n / n with high metal gettering ability based on heavily phosphorus-doped Czochralski silicon + A method for preparing a silicon epitaxial wafer, comprising the following steps:

[0116] 1) Choose heavily phosphorus-doped Czochralski silicon with a diameter of 200mm in the crystal orientation as n / n + The substrate of the silicon epitaxial wafer, the substrate resistivity is 0.002~0.004Ω·cm, and the oxygen concentration is 1.5×10 18 / cm 3 ;

[0117] 2) After the heavily arsenic-doped Czochralski silicon was cleaned by RCA, it was placed in high-purity N 2 Heat treatment at 1100°C for 200s in a rapid heat treatment furnace under atmosphere, and rapidly cool at a cooling rate of 40°C / s to obtain a nitrogen-doped heavily phosphorus-doped Czochralski silicon substrate;

[0118] 3) Place the nitrogen-doped heavily phosphorus-doped Czochralski silicon substrate in an epitaxial furnace, and grow a lightly phosphorus-doped silicon epitaxial layer with a thickne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com