Method for non-epitaxially growing semiconductor

A non-epitaxial growth and semiconductor technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems that cannot meet the needs of single crystal semiconductors, and achieve the effects of low cost, cheap and easy-to-obtain raw materials, and simple devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

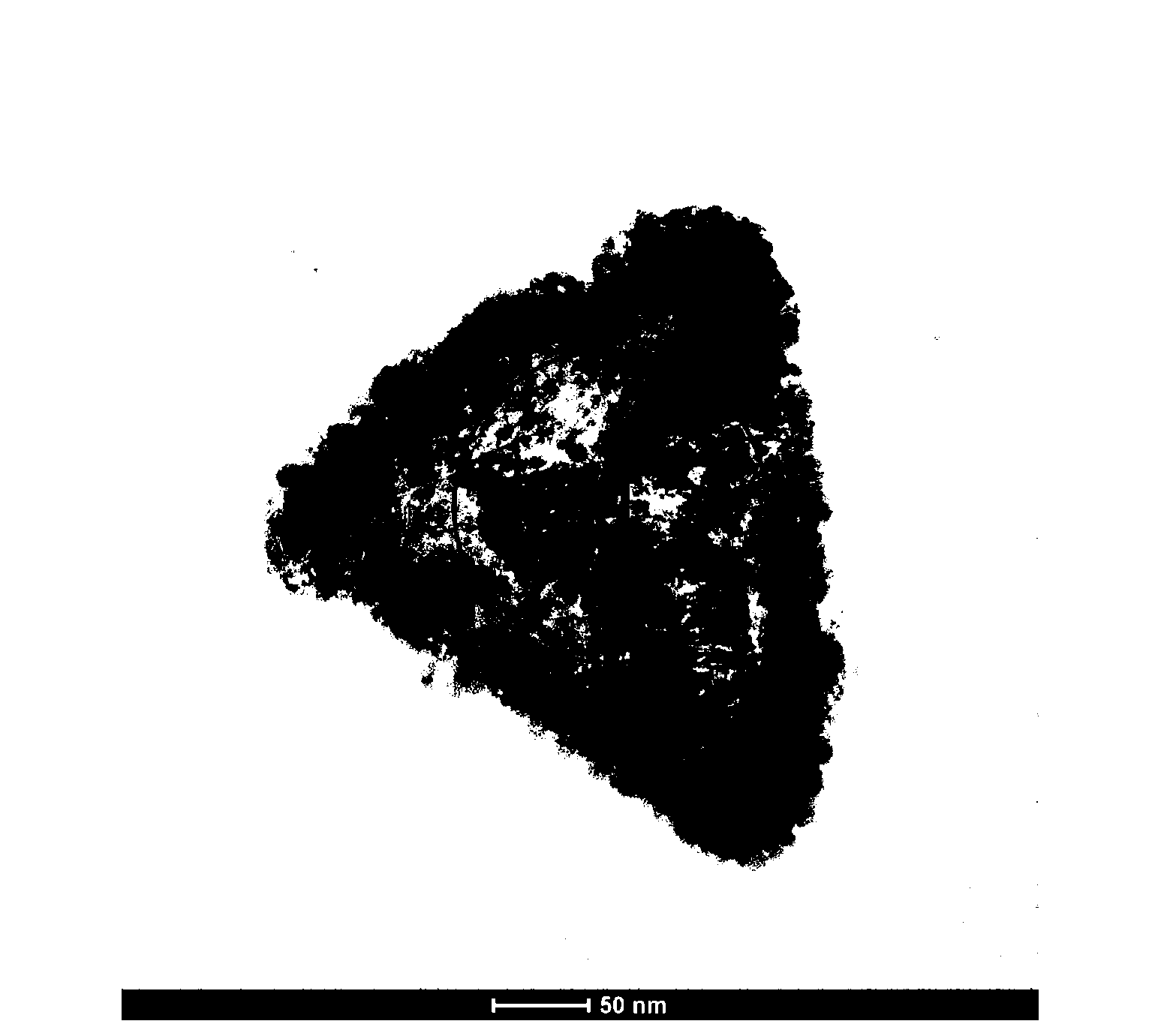

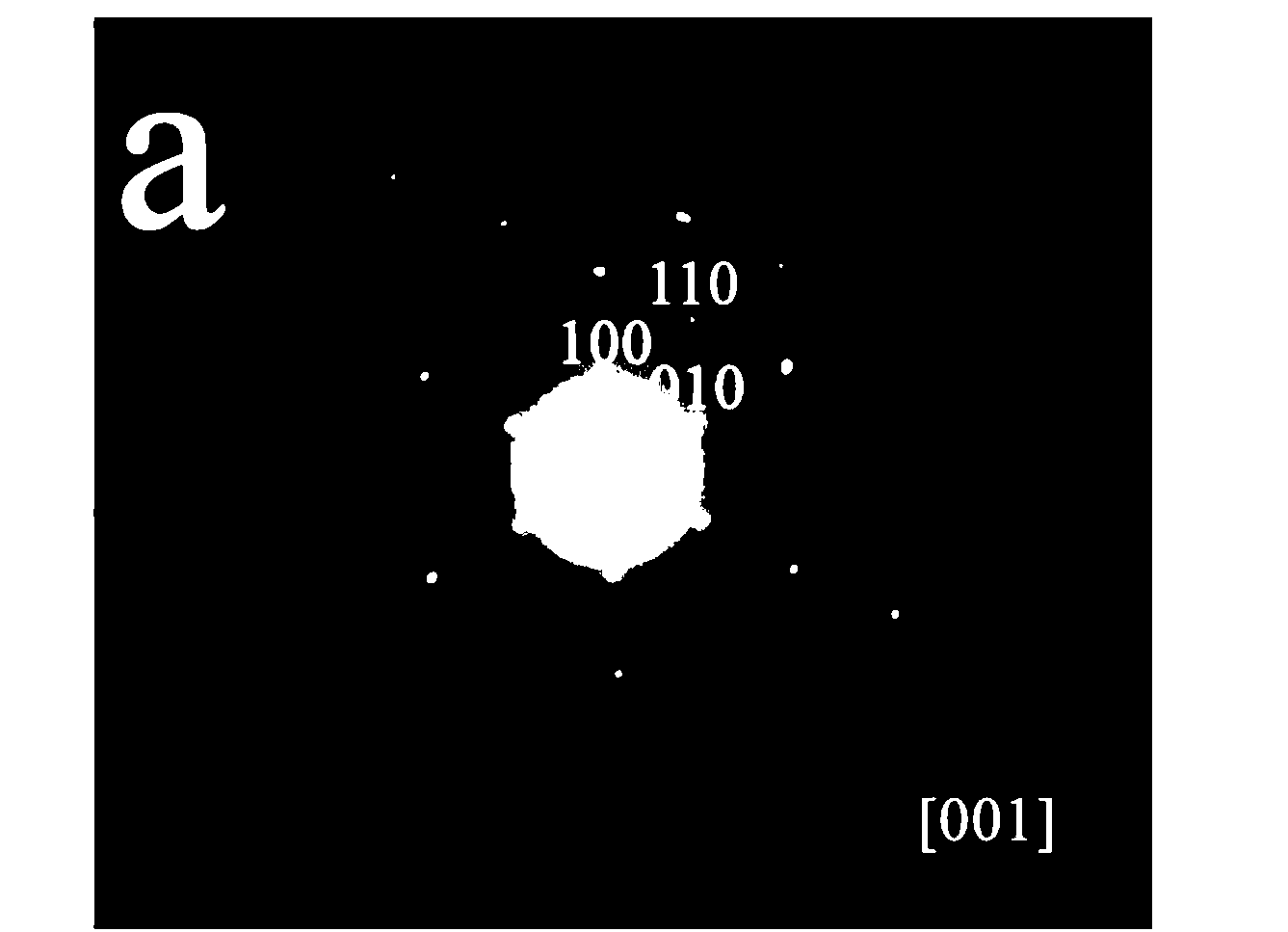

[0042] (1) Preparation of silver flake sol

[0043] 0.169g AgNO 3 Dissolve in 20ml N-N dimethylformamide (DMF) to obtain mixed solution 1, dissolve 0.111g polyvinylpyrrolidone (PVP) in 20ml DMF to obtain mixed solution 2, after mixed solution 1 gradually changes from colorless to light yellow , dropwise added to the mixed solution 2, and magnetically stirred at room temperature for 8 minutes to obtain an orange-yellow solution, which was then sealed in a reaction kettle, and reacted in an oven at 140°C for 18 hours, and then centrifuged with ethanol at 2000rpm for 3 times. It takes 15 minutes to disperse with ethanol or water to obtain 0.03 mol / L silver flake ethanol sol or silver flake hydrosol with micro / nano structure.

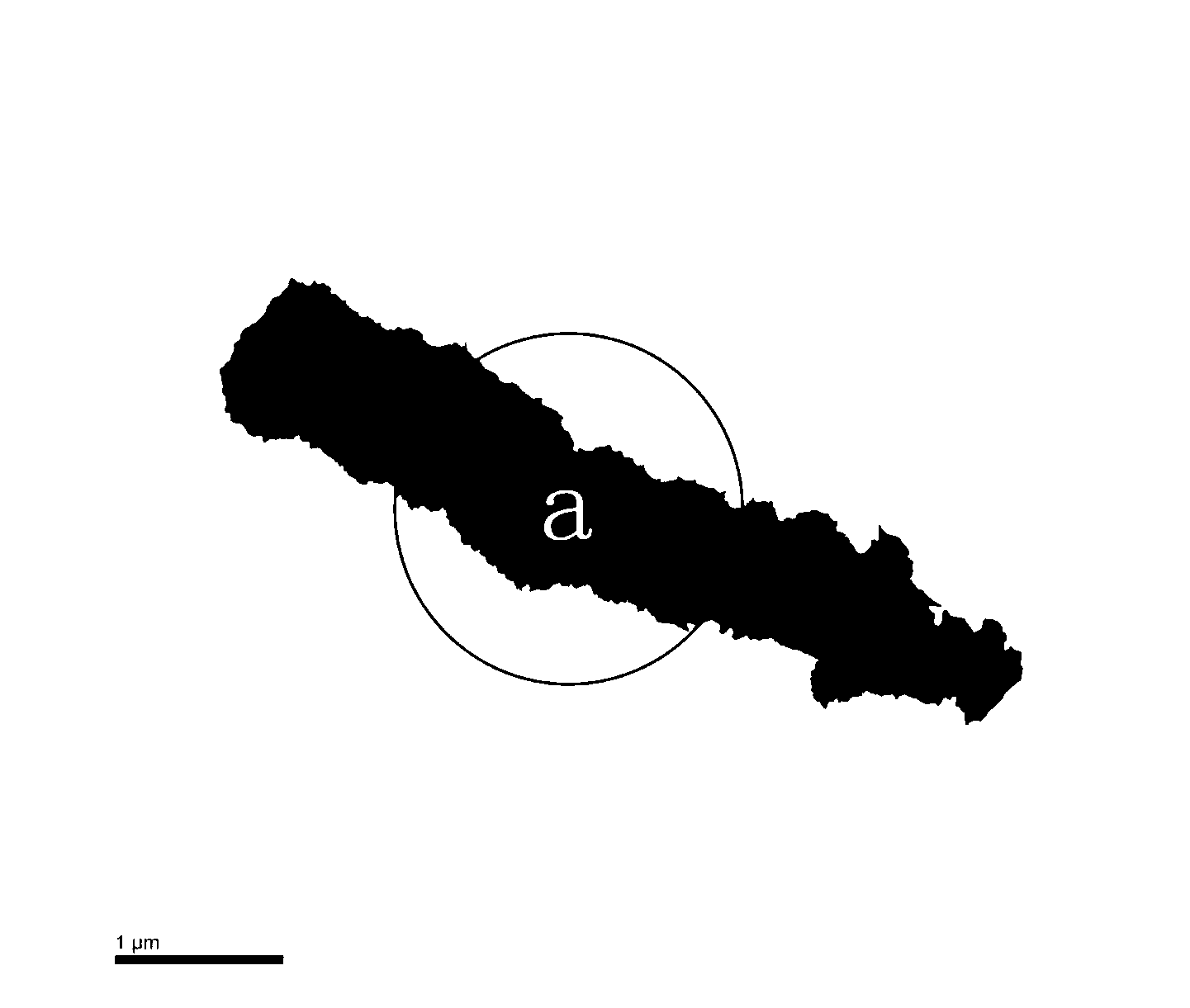

[0044] (2) Preparation of silver sol with one-dimensional ribbon structure

[0045] 3.0g PVP was dissolved in 25ml DMF to obtain mixed solution 1, and then 0.172g AgNO 3 Dissolve in the mixed solution 1 to obtain the mixed solution 2. After the mixed solut...

Embodiment 2

[0053] (1) In a clean area of 1cm 2 Drop 4 drops (20ul / drop) of the silver flake ethanol sol prepared in Example 1 (1) on the ordinary glass substrate material, and let it dry naturally at room temperature. With the volatilization of ethanol, the silver flakes The silver film is self-assembled on the substrate material, and due to the van der Waals force and electrostatic attraction, it is firmly combined with the ordinary glass sheet; the ordinary glass sheet coated with the silver film is placed in a 50ml volume weighing bottle, and the silver film is on one side Upward, add 5ml of absolute ethanol and 300μl of 1-thiodecane in acetone with a substance concentration of 10%, let it stand for 8min, add 3ml of the sulfur precursor solution prepared in Example 1 (3), and mix Evenly, after sealing the lid, put it in an ordinary blast oven at 65 ° C for 5 hours to complete the reaction, take out the substrate material, soak and wash it with absolute ethanol for 3 times, and dry i...

Embodiment 3

[0057] (1) Treat an area of 2.25cm with 3-aminopropyltrimethoxysilane 2 clean PET conductive film substrate material, so that its wettability to water reaches complete infiltration, then on one side of its conductive layer, drop 10 drops (20ul / drop) of the silver flake hydrosol prepared in embodiment 1 (1) , dried in a vacuum drying oven at 50°C to form a uniform silver film, and due to the van der Waals force and electrostatic attraction, it is firmly combined with the PET conductive film; the PET conductive film coated with silver film is placed in a 50ml volume weighing In the measuring bottle, the side that is plated with the silver film faces up, and the absolute ethanol of 10ml and the concentration of 600 μl of substance are added to the acetone solution of 10% 1-thiodecane, let stand for 10min, add 6ml of Example 1 ( 3) For the prepared sulfur precursor solution, soak the PET conductive film coated with silver film in the above solution, then seal the weighing bottle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com