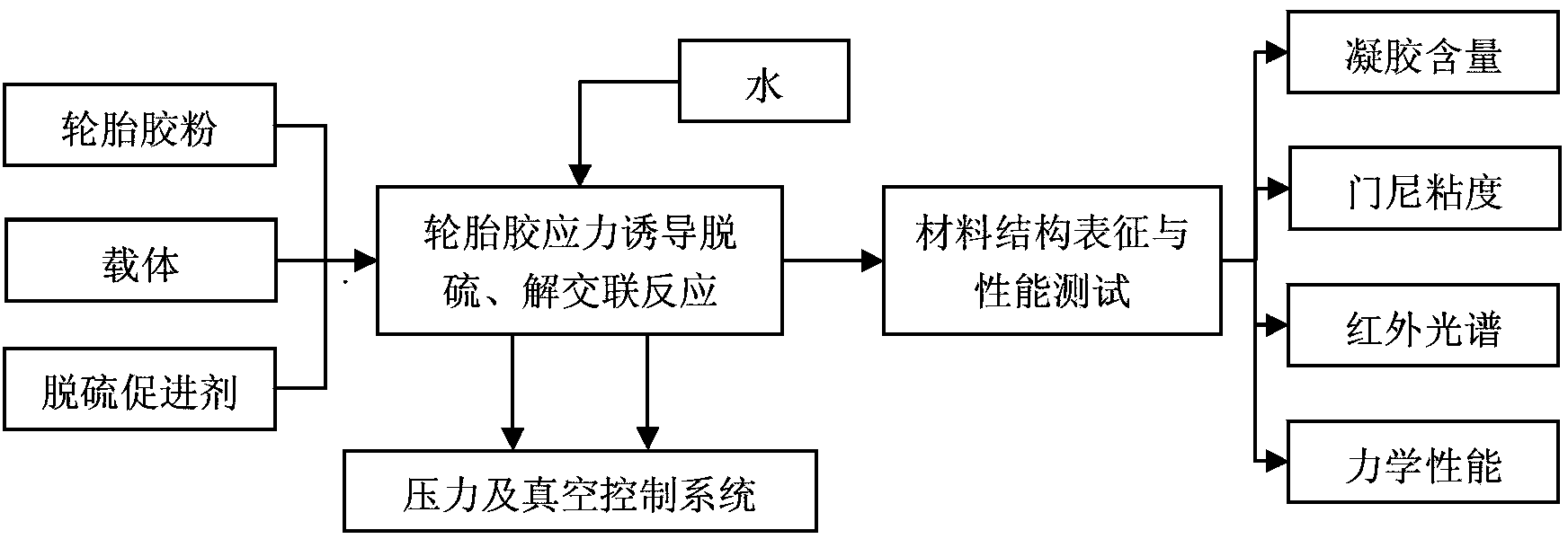

Method for inducing desulfurization reaction of vulcanized rubber powder through stress of subcritical water extrusion method

A technology of vulcanized rubber powder and subcritical water, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of solid polymer without shearing, mixing and surface renewal, discontinuous process, high temperature, pressure and other problems , to achieve the effect of easy automation, improved mechanical properties, and improved fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1: The rubber powder is mainly composed of leftovers in the production process of car tires. It is determined that it is mainly 80 mesh SBR-based tire rubber powder, provided by Yangzhou Lvhuan Rubber Co., Ltd. According to the thermogravimetric analysis of the rubber powder, the composition of the rubber powder is as follows: volatile matter accounts for 5.5%, rubber content accounts for 46.7%, carbon black content accounts for 37.2% and ash content accounts for 10.5%.

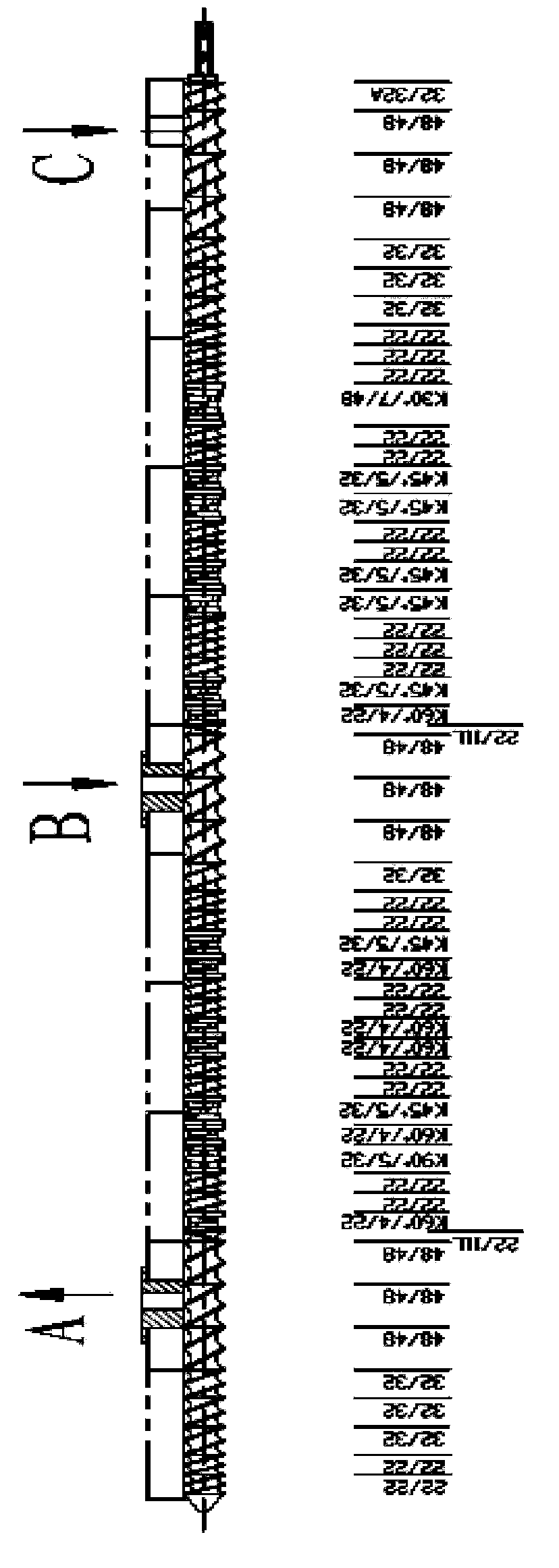

[0043] Mix 800 grams of the above tire rubber powder with 200 grams of EPDM4770 (sub-brand, DuPont-Dow, USA) and 30 grams of distilled water; add the mixture to a third-order co-rotating screw with a diameter of 35 mm and an aspect ratio of 44. In the rotary twin-screw extruder (Nanjing Coperion-Keya Machinery Equipment Co., Ltd.); the extrusion temperature is controlled at 180°C, 200°C and 220°C, and the screw speed is 400rpm, 600rpm, 800rpm, 1000rpm, 1200rpm; Water is metered and injected at ...

Embodiment 2

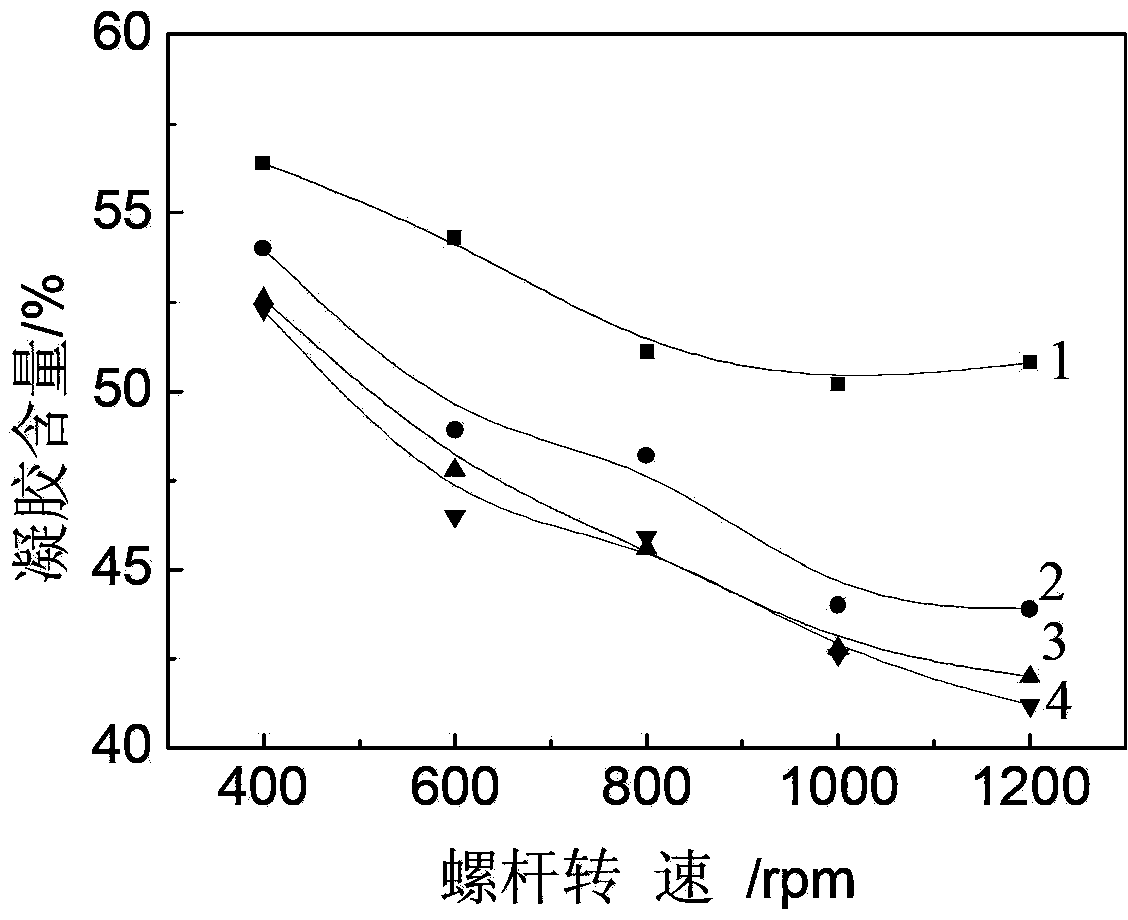

[0052] Embodiment 2: Mix 800 grams of the above-mentioned tire rubber powder with 200 grams of EPDM4770 (sub-brand, DuPont-Dow Company of the United States), 30 grams of distilled water and 0.3% desulfurization accelerator: hydrogen peroxide H 2 o 2 , alkylphenol polysulfide 450 or H 2 o 2 Mixed with the compound of 450; the mixture was added to the twin-screw extruder; the extrusion temperature was controlled at 200°C, the pressure was 1.6MPa, and the screw speed was 400rpm, 600rpm, 800rpm, 1000rpm, and 1200rpm; others were the same as in Example 1 Same, the gel content and Mooney viscosity value of the obtained desulfurization product refer to Figure 7 and Figure 8 .

Embodiment 3

[0058] Embodiment three: the above-mentioned SBR-based tire rubber powder is mixed with HDPE at a mass ratio of 70:30, and 1.5% desulfurization accelerator is added. After the materials are mixed evenly, melt extrusion desulfurization reaction is carried out in a twin-screw extruder. At the same time as the reaction, turn on the metering pump to inject an appropriate amount of water into the extruder through the water injection port B to form a subcritical state of water. The extrusion temperature is 220°C, the subcritical water pressure is 2.4MPa, and the screw speed is 1000rpm. In this state, the extrusion desulfurization reaction of tire rubber powder is carried out. The volatile gas generated during the extrusion reaction process was removed by a vacuum system, and the extruded product was water-cooled and pelletized to obtain a desulfurized blend (DGTR / HDPE), and the desulfurized blend was dried in a vacuum oven at 80°C for 6 hours.

[0059] Mix 60 parts (parts by mass, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com