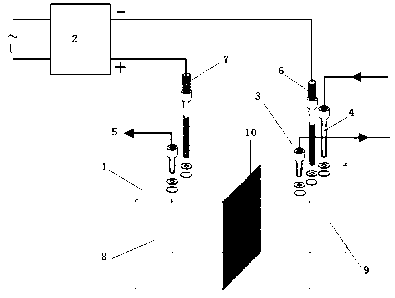

Method and device for purifying hydrogen cyanide industrial waste gas by electrodialysis

An industrial waste gas and electrodialysis technology, applied in the field of environmental engineering, can solve the problems of high energy consumption, poor hydrogen oxide removal effect, and reduce hydrogen cyanide content, etc., to achieve high gas purification rate, increase capacity, and increase purification volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the method and the device of electrodialysis purification hydrogen cyanide industrial waste gas, specific content is as follows:

[0035] 1. The preparation of cobalt-containing perfluorosulfonic acid ion exchange membrane, the specific steps are as follows:

[0036] (1) With perfluoroperoxide (2-(2-fluorosulfonylethoxy)-propyl vinyl ether) as the initiator, fluorine-containing compounds (tetrafluoroethylene and hexafluoropropylene in a molar ratio of 1:1 prepared by mixing in the ratio of ) as a mixed solvent, mix and stir the two substances evenly, separate the precipitate, wash the precipitate three times, dry at 90°C, and melt and extrude at 160°C to obtain -SO 2 Perfluorosulfonic acid precursor resin of F group, wherein the molar ratio of initiator to fluorine-containing compound is 1:1;

[0037] (2) According to the ratio of adding 20ml of cobalt-containing NaOH aqueous solution per gram of perfluorosulfonic acid precursor resin, add perfluorosulfon...

Embodiment 2

[0044] Embodiment 2: the method and the device of electrodialysis purification hydrogen cyanide industrial waste gas, specific content is as follows:

[0045] 1. The preparation of cobalt-containing perfluorosulfonic acid ion exchange membrane, the specific steps are as follows:

[0046] (1) With perfluoroperoxide (2-(2-fluorosulfonylethoxy)-propyl vinyl ether) as the initiator, fluorine-containing compounds (tetrafluoroethylene and hexafluoropropylene in a molar ratio of 1:1 prepared by mixing the ratio) as a mixed solvent, mix and stir the two substances evenly, separate the precipitate, wash the precipitate 4 times, dry at 100°C, and melt extrude at 200°C to obtain -SO 2 The perfluorosulfonic acid precursor resin of the F group, wherein the molar ratio of the initiator to the fluorine-containing compound is 0.5:1;

[0047] (2) According to the ratio of adding 50ml of cobalt-containing NaOH aqueous solution per gram of perfluorosulfonic acid precursor resin, add perfluorosu...

Embodiment 3

[0053] Embodiment 3: the method and the device of electrodialysis purification hydrogen cyanide industrial waste gas, specific content is as follows:

[0054] 1. The preparation of cobalt-containing perfluorosulfonic acid ion exchange membrane, the specific steps are as follows:

[0055] (1) With perfluoroperoxide (2-(2-fluorosulfonylethoxy)-propyl vinyl ether) as the initiator, fluorine-containing compounds (tetrafluoroethylene and hexafluoropropylene in a molar ratio of 1:1 Mixed in the proportion prepared) as a mixed solvent, the two substances were mixed and stirred evenly, separated and precipitated, and the precipitate was washed with water: after 5 times, it was dried at 80°C and melted and extruded at 150°C to obtain -SO 2 Perfluorosulfonic acid precursor resin of F group, wherein the molar ratio of initiator to fluorine-containing compound is 2:1;

[0056] (2) According to the ratio of adding 35ml of cobalt-containing NaOH aqueous solution per gram of perfluorosulfon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com