Pressurized high-temperature nitriding device with dual-pressure balance structure

A double-pressure balance, high-temperature nitriding technology, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of reducing the overall life of the nitriding device, furnace material creep, and equipment cost increase , to achieve the effect of slowing down the wear rate of equipment, preventing high temperature creep and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

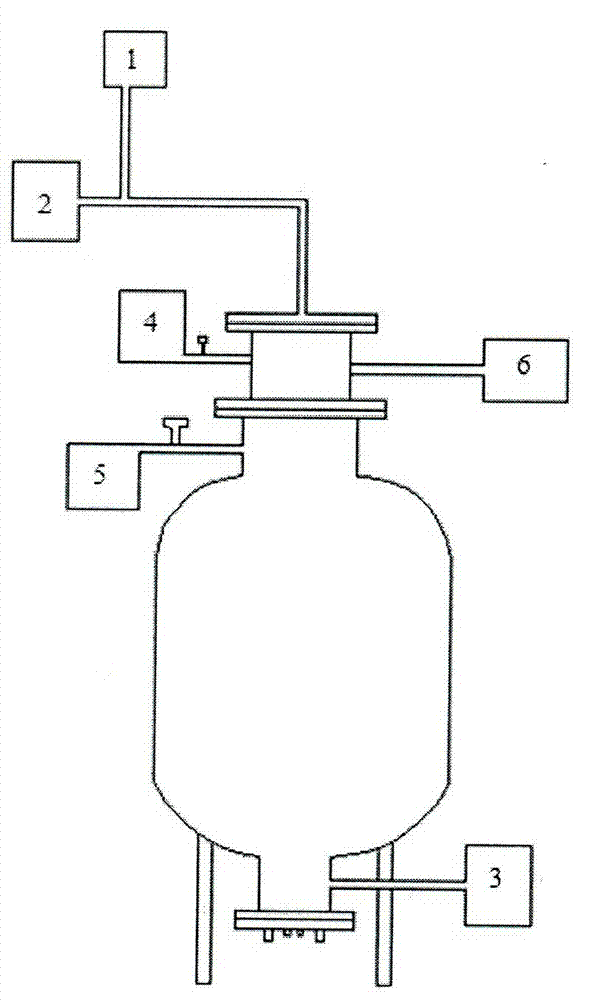

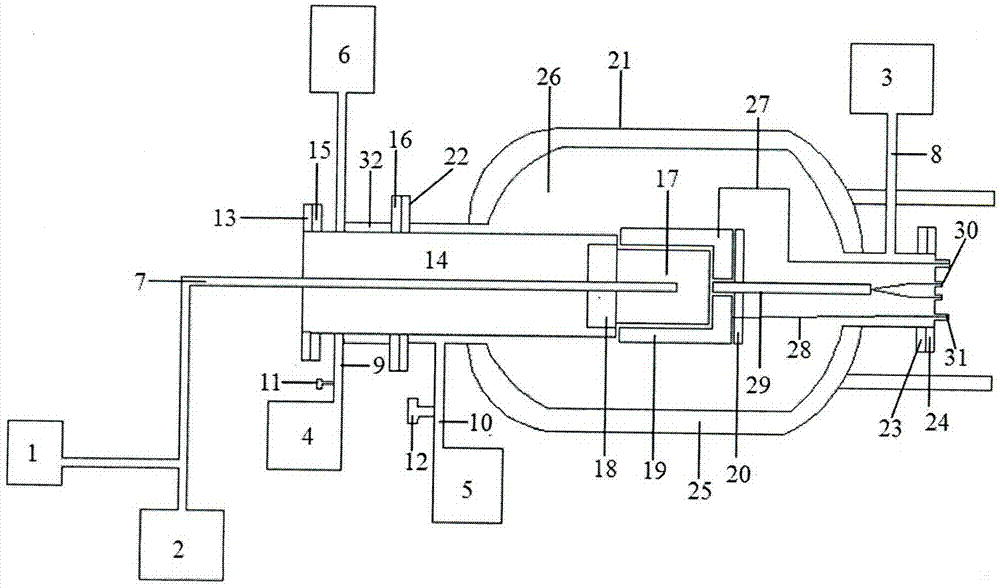

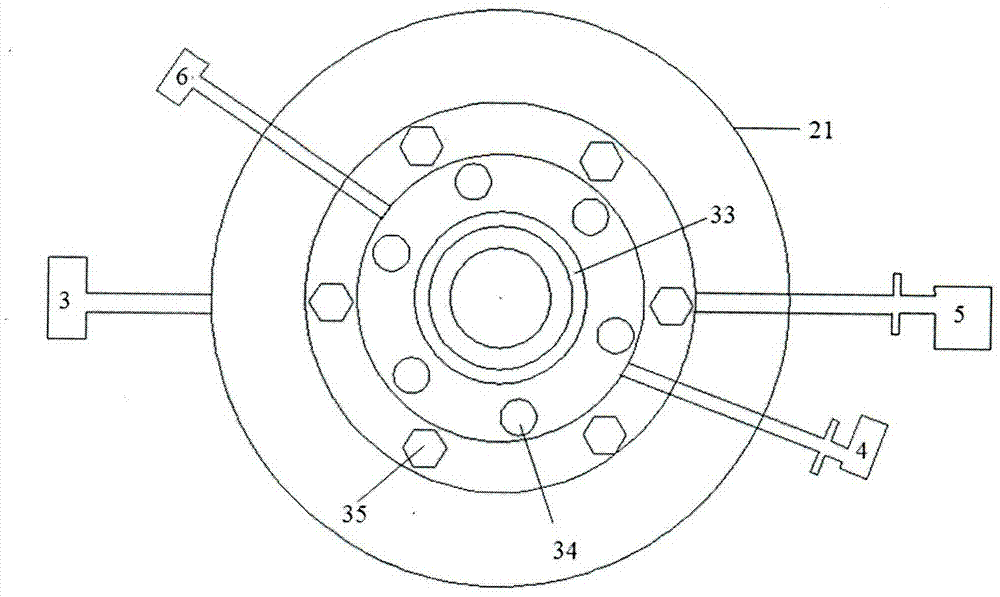

[0021] The nitriding device of the present invention adopts an internal and external dual-pressure balance structure, which consists of a reaction furnace, a circular furnace shell, a gas charging / deflation system, a vacuum system, a circulating water system, a flow monitoring system, a pressure monitoring device, a waste gas collection system, and a temperature measurement system. devices etc. The main structure mainly includes furnace cover, furnace furnace and furnace shell. The furnace cover is equipped with an inflatable pipe, which extends to the reaction chamber at the bottom of the furnace. The reaction chamber is nested by the heating furnace tube. The center of the bottom of the furnace tube is opened and supported by a ceramic plate. The upper end of the furnace is equipped with a vacuum and exhaust device, the exhaust end is equipped with a flow monitor, and a circulating water jacket is installed between the upper and lower flanges of the furnace. The shell is eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com