Free-cutting lead and zinc containing white copper and machining method thereof

A zinc-nickel-nickel, easy-cutting technology, applied in the field of free-cutting lead-containing zinc-nickel copper and its processing, can solve the problems of difficult cold working, difficult hot working, easy cracking, etc., and achieves the effect of shortening the processing cycle, long processing cycle and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

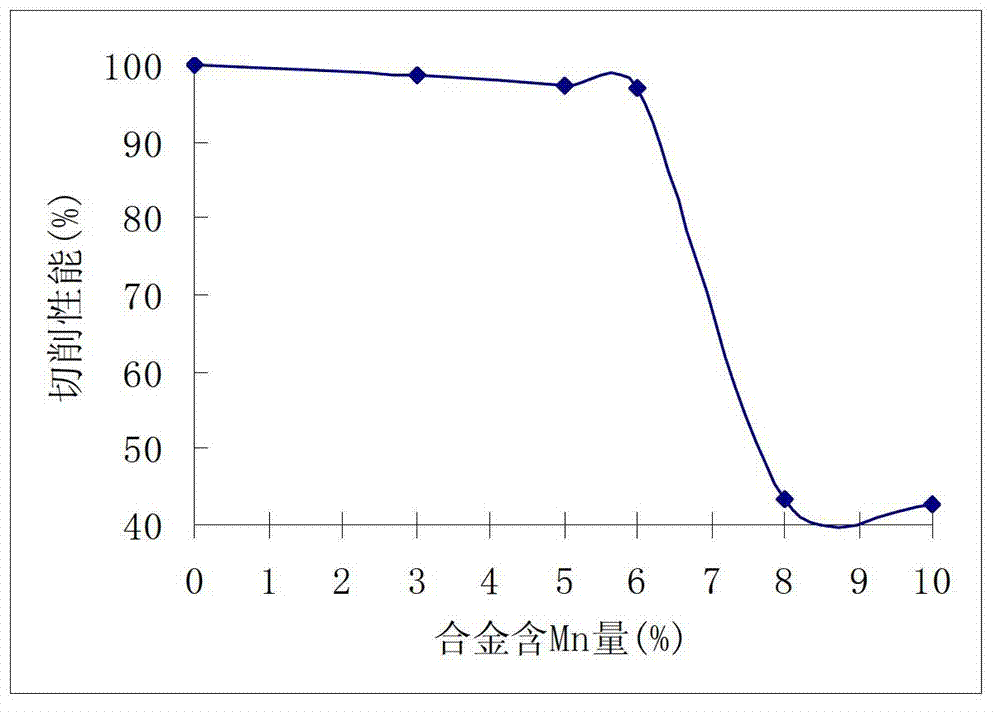

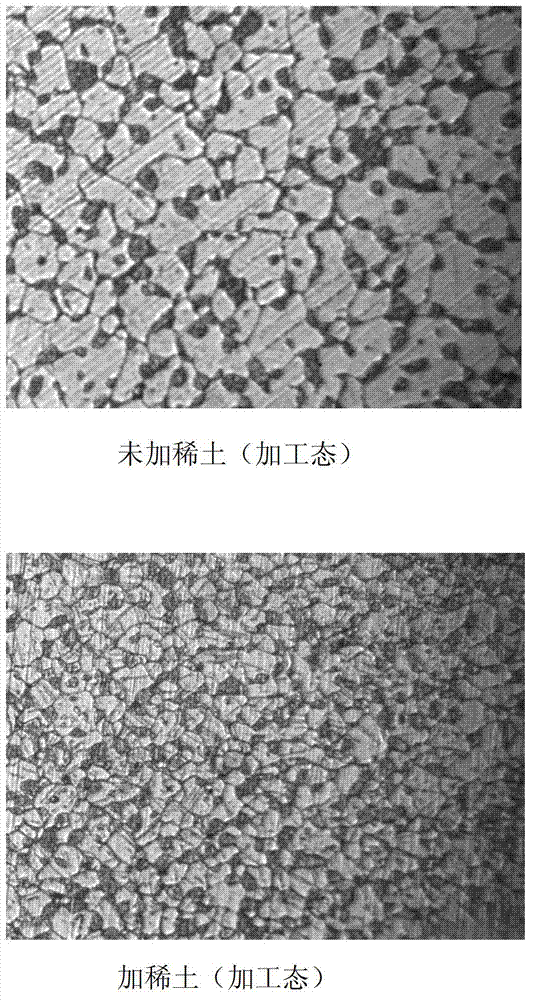

[0025] The free-cutting lead-zinc nickel-copper alloy of the present invention comprises the following components in weight percent: copper 43.0%-47.0%, nickel 10.0%-14.0%, lead 1.0%-1.5%, manganese 3.0%-6.0%, rare earth 0.04%- 0.08%, the balance is zinc and unavoidable impurities, and the sum of the contents of each component is 100%.

[0026] The processing method of the free-cutting lead-zinc white copper of the present invention is as follows: the above-mentioned components are alloyed at 1000°C~1200°C for alloy smelting, and then semi-continuously cast into φ100mm~φ120mm round billets at a casting temperature of 1050°C~1150°C After sawing off the round bar, hot extrusion is carried out. The hot extrusion temperature is 750°C~850°C. After hot extrusion, the wire billet is subjected to butt welding, rounding, cold processing and heat treatment. The cold processing rate is 0~40%. Heat treatment is at 600℃~680℃ for 1~2h.

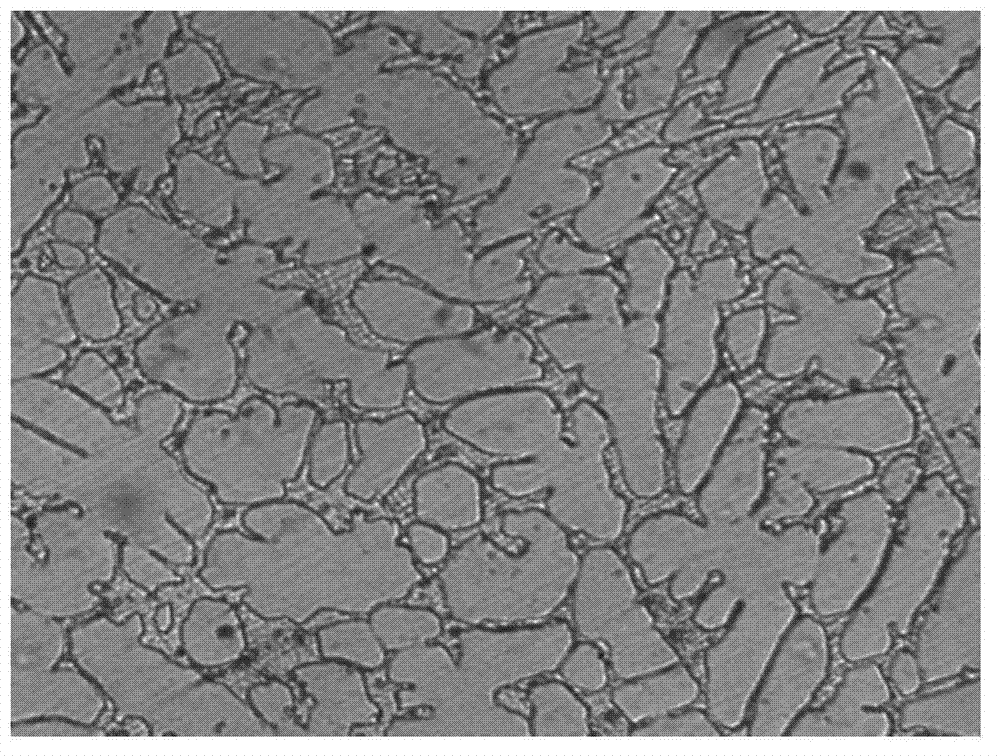

[0027] The metallographic structure of the above-men...

Embodiment 2

[0033] The material composition is:

[0034]44.0wt% Cu, 12.0wt% Ni, 5.0wt% Mn, 1.4wt% Pb, 0.06wt% Ce, the balance is Zn, and the sum of the contents of each component is 100%.

[0035] According to the material composition, the ingredients are melted in the intermediate frequency furnace (or power frequency furnace), and then semi-continuously cast into a φ120mm round ingot, sawing the ingot to a length of 400mm, hot extruding into a φ6mm wire billet, cold drawing and heat treatment, and finally processed into the desired shape of the customer. required wire. Such as processing into φ2.3mm wire for the pen core manufacturer to produce the nib.

Embodiment 3

[0037] The material composition is:

[0038] 43.0wt% Cu, 12.5wt% Ni, 5.0wt% Mn, 1.3wt% Pb, 0.06wt% La, the balance is Zn, and the sum of the contents of each component is 100%.

[0039] According to the material composition, the ingredients are melted in an intermediate frequency furnace (or power frequency furnace), and then semi-continuously cast into a φ100mm round ingot, sawing the ingot to a length of 400mm, and extruding it into a special-shaped billet, and then drawing it into various shapes at room temperature. The special profiles are used for eyeglass ingredient manufacturers to produce eyeglass hinges and zipper factories to produce zippers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com