Water-based ultrathin expansion type formed steel construction fire retardant coating based on expansible graphite and crystal whisker system

A technology of expanded graphite and fireproof coatings, applied in fireproof coatings, epoxy resin coatings, coatings, etc., can solve the problems of fireproof coatings without anticorrosion function, accelerated corrosion of steel structures, and limited application of fireproofing, so as to improve hardness, Improve adhesion and improve peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Step 1: Preparation of Modified Expandable Graphite

[0041] Add 50g polyethylene glycol monomethyl ether, 500ml dehydrated alcohol, 500ml deionized water in reactor, heat to 80 ℃ while stirring, after polyethylene glycol monomethyl ether dissolves, add 200g expandable graphite, Stir and disperse for 3 hours, filter, and dry at 60° C. for 12 hours to obtain polyethylene glycol monomethyl ether modified expandable graphite.

[0042] Step 2: 360g pentaerythritol, 90g dipentaerythritol, 600g high degree of polymerization ammonium polyphosphate, 200g melamine phosphate, 125g melamine cyanuric acid, 275g melamine, 50g titanium dioxide, 50g kaolin, 175g composite zinc phosphate, 120g basic magnesium sulfate whiskers , 30g of magnesium borate whiskers and 175g of the modified expandable graphite obtained in step 1 were added to 850g of deionized water, dispersed at high speed for about 30min, and then transferred to a three-roll mill (or ball mill or sand mill) for grinding, f...

Embodiment 2

[0047] Please refer to formula 2 in Table 2, increase the amount of fire retardant additives, relatively reduce the amount of pigments and fillers and composite zinc phosphate, the preparation method is the same as in Example 1, and the properties of the resulting fire retardant coating are shown in Example 2 in Table 3.

Embodiment 3

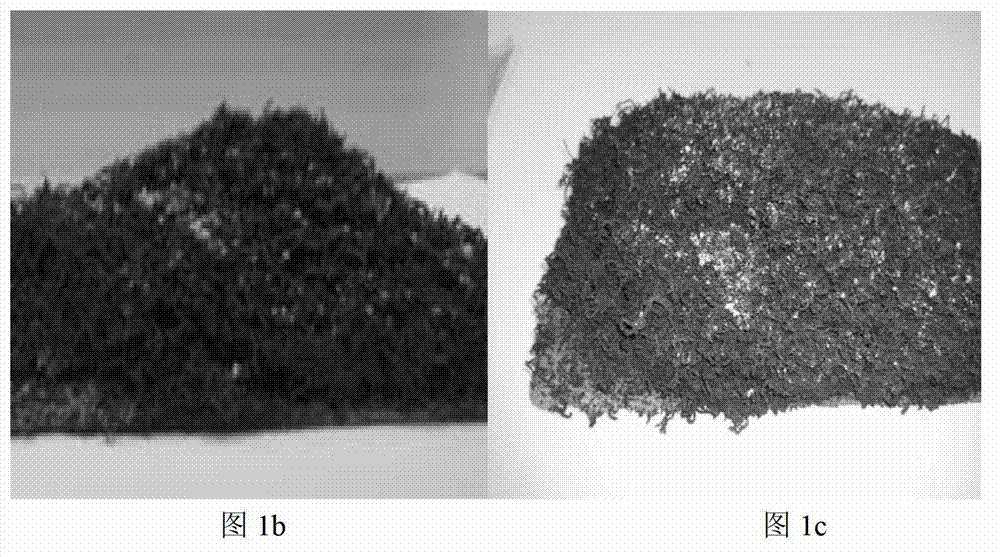

[0049] Please refer to formula 3 of table 2, relatively increase the consumption of expandable graphite and whisker, its preparation method is the same as embodiment 1, the performance of the obtained fireproof coating is shown in embodiment 3 of table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com