Preparation method of silicon dioxide aerogel

A silica and aerogel technology, applied in the direction of silica and silica, can solve the problems of limitation, temperature and pressure below the critical point, and long process cycle, so as to improve the degree and strength of the network, Promote the formation of nanopores, reduce shrinkage and cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing silica airgel, comprising the following steps: A) adjusting the pH value of the silica sol to 4-10 with reducing acid, adding ethanol, heating and keeping warm to obtain a wet gel; B) Mix the wet gel, tetraethyl orthosilicate and ethanol for aging to obtain an alcohol gel; C) mix the alcohol gel with drying control chemical additives, heat and dry under normal pressure to obtain silica gas condensation glue.

[0034] Wherein, the silica sol can be a silica sol well-known to those skilled in the art, and its source is not limited. Silica sol is alkaline, and its pH value needs to be adjusted by adding a reducing acid dropwise to obtain a wet gel. The reducing acid may be a reducing acid well known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably hydrochloric acid, more preferably 1 mol / L hydrochloric acid. Adjust the pH value of the silica sol to 4-10, preferably 5-...

Embodiment 1

[0048] 1.1 Adjust the pH of 200 g of silica sol to 6 with 1 mol / L hydrochloric acid, slowly add 100 mL of ethanol, and keep it in a 50°C water bath for 24 hours to obtain wet gel.

[0049] 1.2 Put the wet gel obtained in 1.1 in 500ml of ethanol, soak it at 50°C for 24h, soak it twice in a row, then add 300mL of a mixed solution of ethyl orthosilicate and ethanol, soak it for 48h for aging, and then use 500mL of Soak in ethanol for 24 hours, and soak for two consecutive times to obtain an alcohol gel, wherein the volume ratio of ethyl orthosilicate and ethanol is 1:4.

[0050] 1.3 Mix the alcohol gel obtained in 1.2 with 7 g of formamide, and place it in an oven at 70° C. to dry for 72 hours to obtain a silica aerogel.

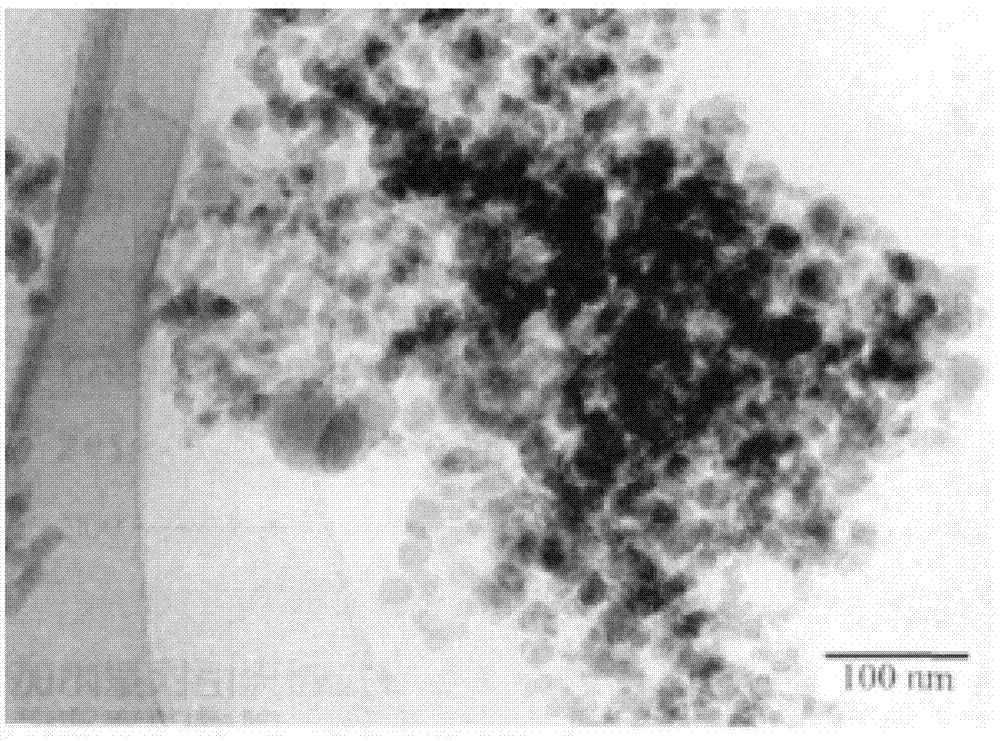

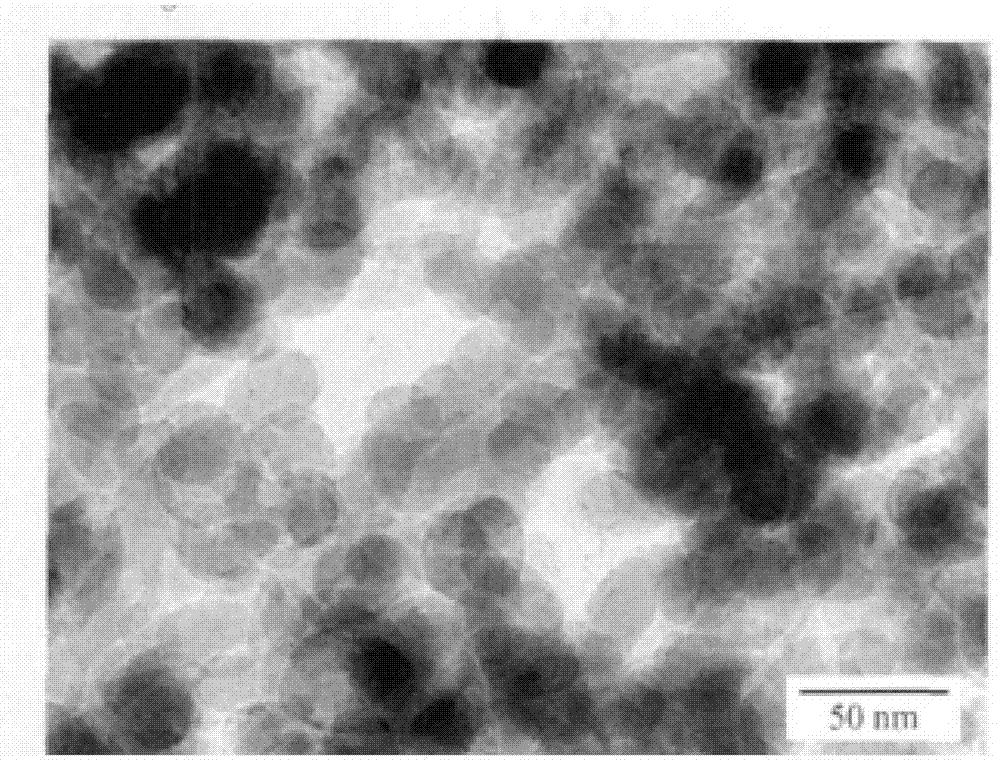

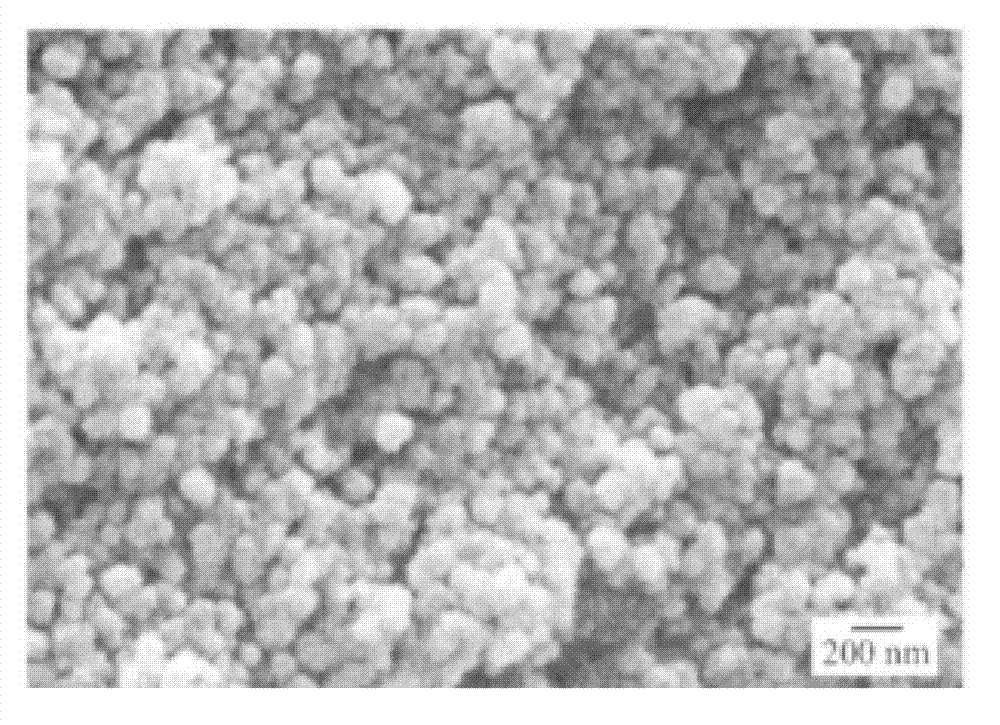

[0051] After grinding and ultrasonically dispersing the silica aerogel obtained in 1.3, it is analyzed by transmission electron microscope to obtain its transmission electron microscope photo, such as figure 1 and figure 2 shown, figure 1 is a 100nm-level T...

Embodiment 2

[0057] 2.1 Adjust the pH of 200 g of silica sol to 8 with 1 mol / L hydrochloric acid, slowly add 80 mL of ethanol, and keep it in a 50°C water bath for 24 hours to obtain a wet gel.

[0058] 2.2 Put the wet gel obtained in 2.1 in 400ml of ethanol, soak it at 50°C for 24h, soak it twice in a row, add 300mL of a mixed solution of ethyl orthosilicate and ethanol, soak it for 48h for aging, and then use 400mL of Soak in ethanol for 24 hours, and soak for two consecutive times to obtain an alcohol gel, wherein the volume ratio of ethyl orthosilicate and ethanol is 1:4.

[0059] 2.3 Mix the alcohol gel obtained in 2.2 with 7 g of formamide, and place it in an oven at 70° C. to dry for 72 hours to obtain a silica aerogel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com