Non-chrome zinc-aluminum coating anticorrosive paint containing nickel-magnesium-silicon

A coating anti-corrosion, zinc-aluminum technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of increased cost, high price, and reduced coating corrosion resistance, and achieve good adhesion, low price, and excellent corrosion resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A nickel-magnesium-silicon-containing chromium-free zinc-aluminum coating is composed of two components A and B in a mass ratio of 3:1, wherein the formula mass percentage of component A is:

[0053] Zinc aluminum alloy powder 32%

[0054]Nano silica 25%

[0055] Sodium lignosulfonate 15%

[0056] Benzotriazole 4%

[0057] Thiodiethylene glycol 0.35%

[0058] Triphenylphosphine 0.35%

[0059] Deionized water balance

[0060] The formula mass percentage of component B is:

[0061] Zirconium tetrafluoride 25%

[0062] γ-Aminopropyltriethoxysilane 18%

[0063] Phytate 14%

[0064] Acetyl cellulose 3.5%

[0065] Ethanol 7%

[0066] Deionized water balance

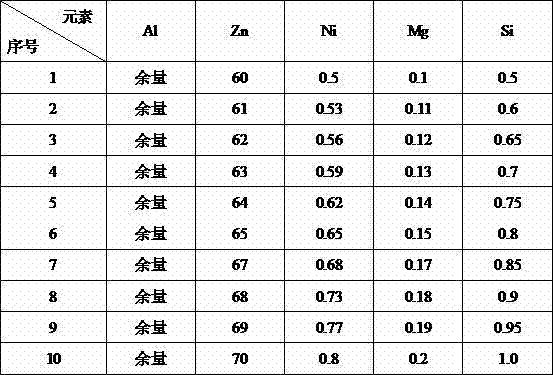

[0067] Wherein, the zinc-aluminum alloy powder is composed of Zn, Al, Ni, Mg, and Si.

[0068] Wherein, the particle size of the nano-silicon dioxide is 20-50 nm.

[0069] The method for preparing the above-mentioned nickel-magnesium-silicon-containing chromium-free zinc-aluminum coating anti-corrosion coati...

Embodiment 2

[0074] A nickel-magnesium-silicon-containing chromium-free zinc-aluminum coating is composed of two components A and B in a mass ratio of 3:1, wherein: the formula mass percentage of component A is:

[0075] Zinc aluminum alloy powder 25%

[0076] Nano silica 30%

[0077] Sodium lignosulfonate 12%

[0078] Benzotriazole 5%

[0079] Thiodiethylene glycol 0.2%

[0080] Triphenylphosphine 0.5%

[0081] Deionized water balance

[0082] The formula mass percentage of component B is:

[0083] Zirconium tetrafluoride 20%

[0084] γ-Aminopropyltriethoxysilane 20%

[0085] Phytate 10%

[0086] Acetyl cellulose 5%

[0087] Ethanol 5%

[0088] Deionized water balance

[0089] Wherein, the zinc-aluminum alloy powder is composed of Zn, Al, Ni, Mg, and Si.

[0090] Wherein, the particle size of the nano-silicon dioxide is 20-50 nm.

[0091] The preparation method is the same as in Example 1.

Embodiment 3

[0093] A nickel-magnesium-silicon-containing chromium-free zinc-aluminum coating is composed of two components A and B in a mass ratio of 3:1, wherein: the formula mass percentage of component A is:

[0094] Zinc-aluminum alloy powder 40%

[0095] Nano silica 20%

[0096] Sodium lignosulfonate 18%

[0097] Benzotriazole 3%

[0098] Thiodiethylene glycol 0.5%

[0099] Triphenylphosphine 0.2%

[0100] Deionized water balance

[0101] The formula mass percentage of component B is:

[0102] Zirconium tetrafluoride 30%

[0103] γ-Aminopropyltriethoxysilane 15%

[0104] Phytate 18%

[0105] Acetyl cellulose 2%

[0106] Ethanol 9%

[0107] Deionized water balance

[0108] Wherein, the zinc-aluminum alloy powder is composed of Zn, Al, Ni, Mg, and Si.

[0109] Wherein, the particle size of the nano-silicon dioxide is 20-50 nm.

[0110] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com