Method for recycling alumina and sodium oxide from bayer process red mud

A Bayer process red mud and alumina technology, applied in the direction of alumina/aluminum hydroxide, alkali metal oxides, etc., can solve problems such as excessive requirements, difficulty in meeting high-efficiency circulation of media, and thermodynamic limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

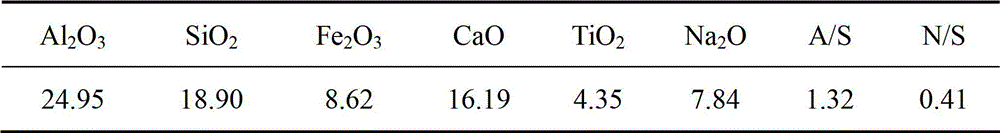

[0066] With the method for recovering alumina and sodium oxide from Bayer process red mud of the present invention, the red mud of a certain Bayer process alumina plant in Henan is used as raw material to recover alumina and sodium oxide. The red mud composition of the alumina plant (mass percentage, wt%, the same below) as described in Table 1:

[0067] Table 1

[0068]

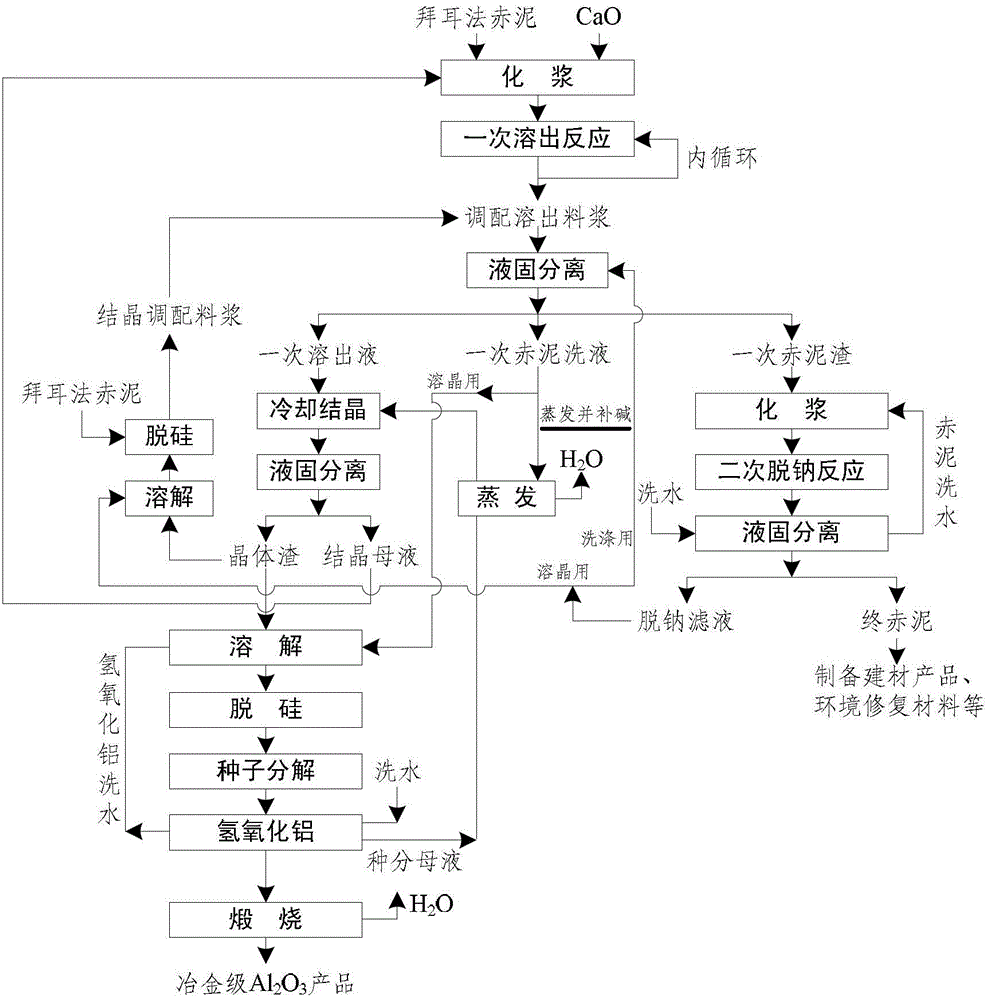

[0069] Its production process is as figure 1 The methods shown include:

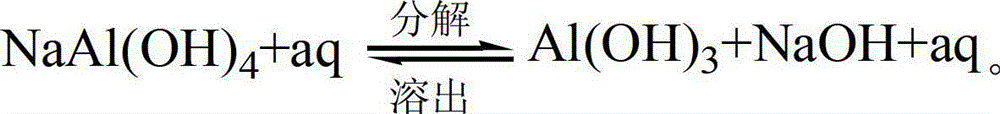

[0070] (1) Mix the red mud of an alumina factory in Henan with concentrated sodium hydroxide solution to prepare a slurry with a liquid NaOH mass fraction of 40% and a ratio of liquid NaOH mass to dry red mud mass of 2.5:1. And add lime to make CaO and SiO in the solid phase 2 The ratio of the amount of the substance is 1.4:1, and then the slurry is placed in a high-pressure reactor for a stripping reaction. The stripping reaction temperature is 210 ° C, and the stripping time is 0.3 hours. The stripping solution containing sodiu...

Embodiment 2

[0076] With the method for reclaiming alumina and sodium oxide from Bayer process red mud of the present invention, the red mud of a certain Bayer process alumina plant in Henan as described in Table 1 is still used as raw material to reclaim alumina and sodium oxide, and the production process is as follows Said:

[0077] (1) Mix the crystallization mother liquor of Example 1 with the prepared concentrated NaOH solution and the Bayer process red mud evenly, and adjust the liquid phase NaOH mass fraction to 50%, and the ratio of the liquid phase NaOH mass to the dry basis red mud mass is 3:1 slurry, and add lime to make CaO and SiO in the solid phase 2 The ratio of the amount of the substance is 1.6:1, and then the slurry is placed in a high-pressure reactor for a stripping reaction. The stripping reaction temperature is 240 ° C, and the stripping time is 0.2 hours, and the stripping solution containing sodium aluminate and slag are obtained. The solid-liquid mixture, the rel...

Embodiment 3

[0083] With the method for reclaiming alumina and sodium oxide from Bayer process red mud of the present invention, the red mud of a certain Bayer process alumina plant in Henan as described in Table 1 is still used as raw material to reclaim alumina and sodium oxide, and the production process is as follows Said:

[0084] (1) Mix the red mud of an alumina plant in Henan with concentrated sodium hydroxide solution to prepare a slurry with a liquid NaOH mass fraction of 55% and a ratio of liquid NaOH mass to dry red mud mass of 4:1. And add lime to make CaO and SiO in the solid phase 2 The ratio of the amount of the substance is 1.3:1, and then the slurry is placed in a high-pressure reactor for a stripping reaction. The stripping reaction temperature is 270 ° C, and the stripping time is 0.5 hours, and the stripping solution containing sodium aluminate and slag are obtained. The solid-liquid mixture, the relative dissolution rate of alumina entering the solution is 88.4%;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com