Glass-fiber-reinforced PA66/PBT (polyamide 66/polybutylene terephthalate) resin alloy material and preparation method thereof

A PBT resin and alloy material technology, applied in the field of glass fiber reinforced PA66/PBT resin alloy material and its preparation, can solve the problems of low notched impact strength and large molding shrinkage rate, and achieve improved performance indicators, improved water absorption, reduced Effects of Recipe Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

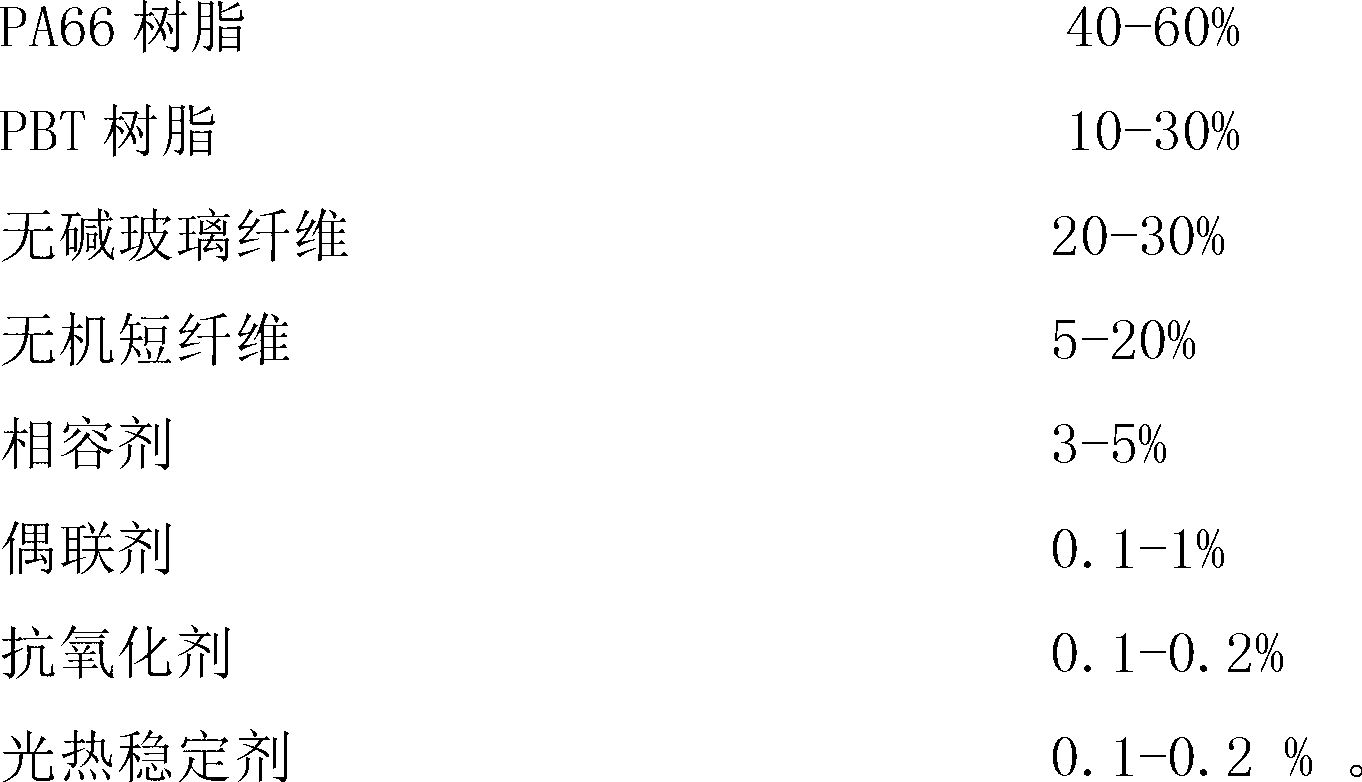

[0026] The formula by mass percentage includes:

[0027] PA66 resin: 40%

[0028] PBT resin: 15%,

[0029] The relative viscosity of the PA66 resin is 2.7-2.9dl / g.

[0030] The PBT resin is polybutylene terephthalate, and its characteristic viscosity number is 0.8-1.2dl / g.

[0031] The alkali-free glass fiber is: 3 strands of ply roving for alkali-free thermoplastics (about 30%)

[0032] The short fiber is: CaCO 3 Whiskers 10%, diameter 5-10nm, aspect ratio 40-50,

[0033] The coupling agent is: 0.5% of 3-aminopropyltrioxysilane,

[0034] Hindered phenolic antioxidant 1076 (chemical name: β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate octadecanoic acid), 0.1%

[0035] Light and heat stabilizer: n-hexadecyl 3,5-di-tert-butyl-4-hydroxybenzoate, 0.1%,

[0036] Compatibilizers are: maleic anhydride (MAH) grafted ethylene-octene elastomer (POE-g-MAH), 2%, silane grafted polyethylene (sxPE), 1%, SEBS-g-MAH, 1% .

[0037] The preparation method is:

[0038] (1) Premixing:...

Embodiment 2

[0064] The formula by mass percentage includes:

[0065] PA66 resin: 45%

[0066] PBT resin: 10%,

[0067] The relative viscosity of the PA66 resin is 2.7-2.9dl / g.

[0068] The PBT resin is polybutylene terephthalate, and its characteristic viscosity number is 0.8-1.2dl / g.

[0069] The alkali-free glass fiber is: 3 strands of ply roving for alkali-free thermoplastics (about 30%)

[0070] The short fiber is: CaSO 3 Whiskers 10%, diameter 5-10nm, aspect ratio 40-50,

[0071] The coupling agent is: 0.5% of 3-aminopropyltrioxysilane,

[0072] Aromatic amine antioxidants: N-phenyl-α-naphthylamine, 0.1%

[0073] Light and heat stabilizer: n-hexadecyl 3,5-di-tert-butyl-4-hydroxybenzoate, 0.1%,

[0074] The compatibilizers are: maleic anhydride (MAH) grafted ethylene-octene elastomer (POE-g-MAH), 1%, silane grafted polyethylene (sxPE), 1%, SEBS-g-MAH, 1% , SMA1%

[0075] The preparation method is:

[0076] (1) Premixing: premix PA66 resin, PBT resin, inorganic short fibers, ...

Embodiment 3

[0079] The formula by mass percentage includes:

[0080] PA66 resin: 40%

[0081] PBT resin: 15%,

[0082] The relative viscosity of the PA66 resin is 2.7-2.9dl / g.

[0083] The PBT resin is polybutylene terephthalate, and its characteristic viscosity number is 0.8-1.2dl / g.

[0084] The alkali-free glass fiber is: 3 strands of ply roving for alkali-free thermoplastics (about 30%)

[0085] The short fiber is: silicon calcium magnesium whisker 10%, diameter 5-10nm, aspect ratio 40-50,

[0086] The coupling agent is: 3-aminopropyltrioxysilane 0.6%,

[0087] Hindered phenolic antioxidant 1076, 0.1%

[0088] Light and heat stabilizer: 2-(2'-hydroxy-5'methylphenyl)benzotriazole 0.15%,

[0089] Compatibilizers are: maleic anhydride (MAH) grafted ethylene-octene elastomer (POE-g-MAH), 2%, silane grafted polyethylene (sxPE), 1%, SEBS-g-MAH, 1%

[0090] The preparation method is:

[0091] (1) Premixing: premix PA66 resin, PBT resin, inorganic short fibers, coupling agent, compati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Relative viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com