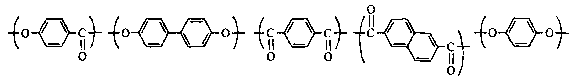

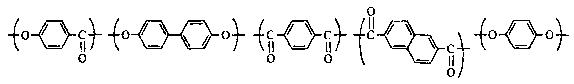

Liquid crystal polymer/cubic boron nitride master batch and preparation method for same

A technology of liquid crystal polymer and cubic boron nitride, which is applied in the field of polymer materials, can solve the problems of poor high temperature resistance and achieve superior scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Add 100 parts of liquid crystal polymer A950 to 5 parts of dimethyl silicone oil and mix for 2 minutes at room temperature in a high-speed mixer; then add 50 parts of cubic boron nitride powder with a particle size of 1000 mesh, and mix for 3 minutes in a high-speed mixer at room temperature. The speed is 100 rev / min;

[0042] (2) Melt and extrude the mixed material through a twin-screw extruder, granulate, and dry to obtain liquid crystal polymer / cubic boron nitride masterbatch; the temperature of the extruder is 200°C, 260°C, 300°C, 320°C, 320°C, 325°C, the length-to-diameter ratio of the screw is 30, and the screw speed is 200 rpm.

[0043] Add 0.5 parts by weight of the liquid crystal polymer / cubic boron nitride masterbatch prepared above into 99.5 parts of PA66 and mix it with a high-speed mixer at room temperature for 2 minutes at a mixing speed of 120 rpm. The product is extruded and granulated by a twin-screw extruder to obtain a modified high-temperature-r...

Embodiment 2

[0057] Add 10 parts of simethicone oil to 100 parts of liquid crystal polymer E6000 and mix it with a high-speed mixer at room temperature for 5 minutes, then add 100 parts of CBN powder with a particle size of 2500 mesh, and mix it with a high-speed mixer at room temperature for 5 minutes. The speed of the mixer is 300 rpm / min, melt and extrude the mixed material through a twin-screw extruder, granulate, dry, and pack. The temperature of the extruder is 200°C, 260°C, 300°C, 320°C, 330°C, and 335°C from the feed to the head, the screw length-to-diameter ratio is 40, and the screw speed is 300 rpm.

[0058] The liquid crystal polymer / cubic boron nitride masterbatch prepared by the above method was added to 94 parts of PA66 in 6 parts by weight and mixed for 5 minutes at room temperature with a high-speed mixer, and the mixing speed was 300 rpm. The mixture is extruded and granulated through a twin-screw extruder. The temperature of each zone of the extruder is 220°C, 260°C, 28...

Embodiment 3

[0061] Add 6 parts of simethicone oil to 100 parts of liquid crystal polymer HX2000 and mix for 3 minutes at room temperature in a high-speed mixer, then add 70 parts of CBN powder with a particle size of 1250 mesh, and mix for 5 minutes in a high-speed mixer at room temperature. The speed of the mixer is 120 rpm / min, melt and extrude the mixed material through a twin-screw extruder, granulate, dry, and pack. The temperature of the extruder is 200°C, 280°C, 300°C, 320°C, 320°C, and 325°C from the feed to the head in sequence, the length-to-diameter ratio of the screw is 35, and the screw speed is 220 rpm.

[0062] The liquid crystal polymer / cubic boron nitride masterbatch prepared by the above method was added to 98 parts of PPS in 2 parts by weight, and mixed at room temperature for 5 minutes by a high-speed mixer, and the mixing speed was 120 revolutions / min. The mixture is extruded and granulated through a twin-screw extruder. The temperature of each zone of the extruder i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com