PC/POK composite material with multilayer structure and preparation method thereof

A composite material, multi-layer structure technology, applied in chemical instruments and methods, household appliances, layered products, etc., can solve the problem of insufficient comprehensive performance of materials, and achieve the effect of improving chemical resistance and gas barrier.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

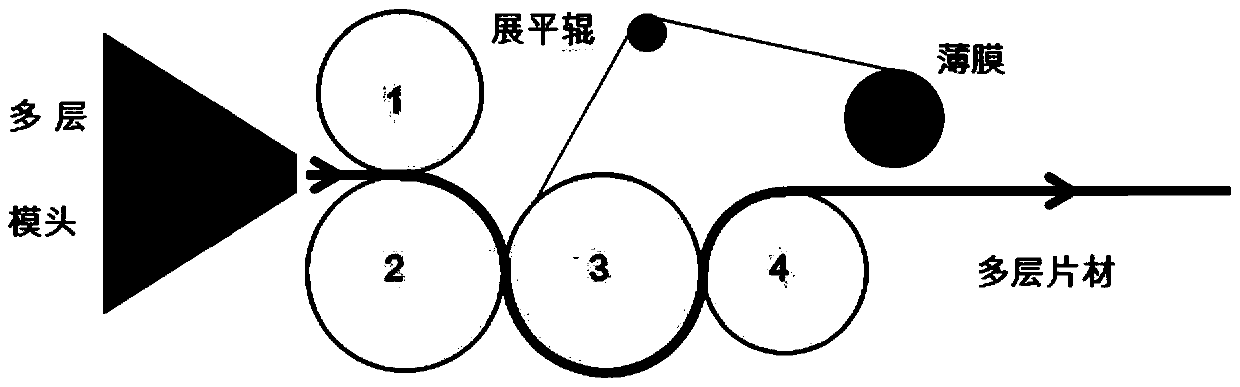

[0029] In this embodiment, a multi-layer coat hanger-type die head is used for co-extrusion, and a multi-layer co-extrusion die head is used to produce POK / PC sheets. Among them, 35mm (screw diameter) single screw extruders are used for POK and PC / ABS / POK. Plastic extrusion, PC is extruded by a 65mm single-screw extruder, POK is on the surface of the sheet, PC is the main material, and PC / ABS / POK is the bonding layer between the PC layer and the POK layer. The thickness is about 10 microns . The material enters the multi-layer die through different melt channels for compounding. The thickness of the POK layer in the formed sheet is 100 microns, and the thickness of the PC layer is 1.2 mm. Among them, the PC and POK raw materials used do not add any components except antioxidants (0.1% Irganox 1010 and 0.1% Irganox 168); and in the PC / ABS / POK system, the ratio of the three components is PC / ABS / POK=55 / 25 / 20.

Embodiment 2

[0031] Multi-layer co-extrusion die head is used to produce POK / high modulus flame-retardant PC sheet, among which POK and PC / ABS / POK are plasticized and extruded by 35mm single screw extruder, and high modulus flame-retardant PC is extruded by 65mm single screw. Extruded from the machine, POK is located on the surface of the sheet, PC is used as the main material, and PC / ABS / POK is used as the bonding layer between the PC layer and the POK layer, with a thickness of about 15 microns. The POK raw materials used do not add any components except antioxidants (0.1% Irganox 1010 and 0.1% Irganox 168); and in the PC / ABS / POK system, the ratio of the three components is PC / ABS / POK=55 / 20 / 25. The high modulus flame-retardant PC layer is realized by adding inorganic fillers and halogen-free flame retardants. For example, the weight ratio of 10% glass fiber and 0.5% aromatic sulfonate (benzenesulfonylbenzenesulfonic acid Potassium) was added to the polycarbonate formulation. The materi...

Embodiment 3

[0033] Multi-layer co-extrusion die head is used to produce POK / high-modulus flame-retardant PC / ABS sheet, among which POK and PC / ABS / POK are plasticized and extruded by a 35mm single-screw extruder, and high-modulus flame-retardant PC / ABS ( The specific composition is PC / ABS=55 / 15) It is extruded by a 65mm single screw extruder, POK is located on the surface of the sheet, PC is used as the main material, and PC / ABS / POK is used as the bonding layer between the PC layer and the POK layer. The thickness is about 15 microns. The POK raw materials used have no added components except antioxidants (0.1% Irganox 1010 and 0.1% Irganox 168); and in the PC / ABS / POK system, the ratio of the three components is PC / ABS / POK =55 / 20 / 25. The high modulus flame-retardant PC / ABS layer is achieved by adding inorganic fillers and halogen-free flame retardants, such as by blending 20% ultrafine talcum powder and 6% phosphate (bisphenol A bis ( Diphenyl phosphate)) was added to the PC / ABS formula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com