Novel positive-temperature-coefficient thermistor element core layer material and application thereof

A technology of thermistor element and positive temperature coefficient, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problems of large space occupied by the circuit board, reduced PTC strength, poor electrical performance and PTC strength, etc., to increase the interface Compatibility, the effect of reducing room temperature resistivity and improving processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Experimental raw materials and ratio

[0054] The types, trade names and sources of raw materials are shown in Table 1; the composition and ratio of raw materials are shown in Table 2.

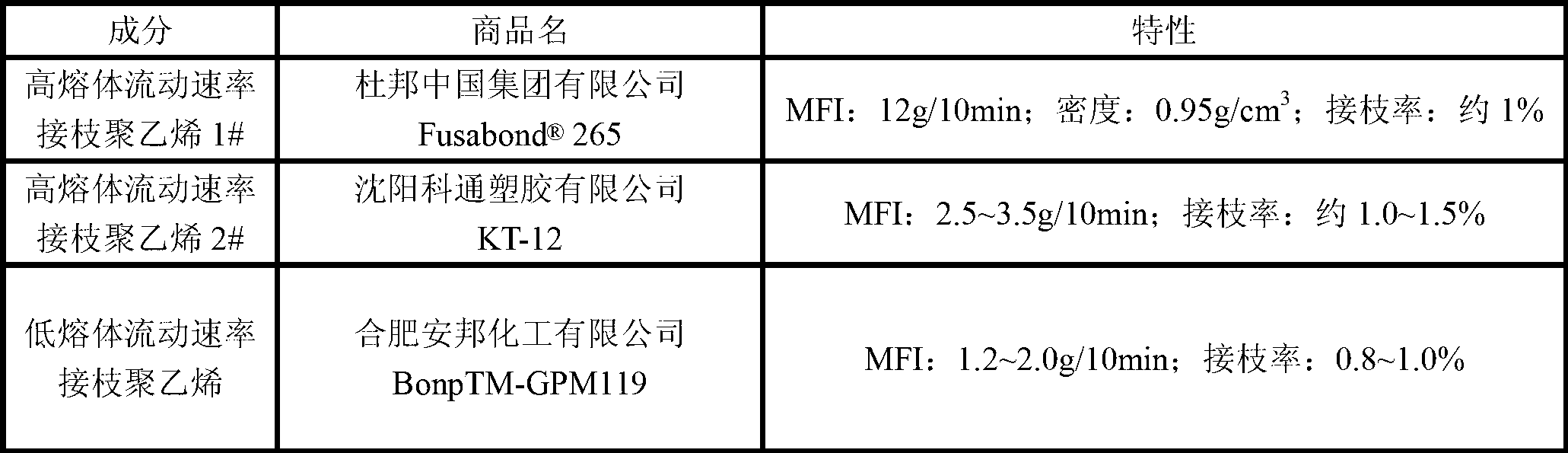

[0055] The raw material source of table 1 comparative example and embodiment

[0056]

[0057]

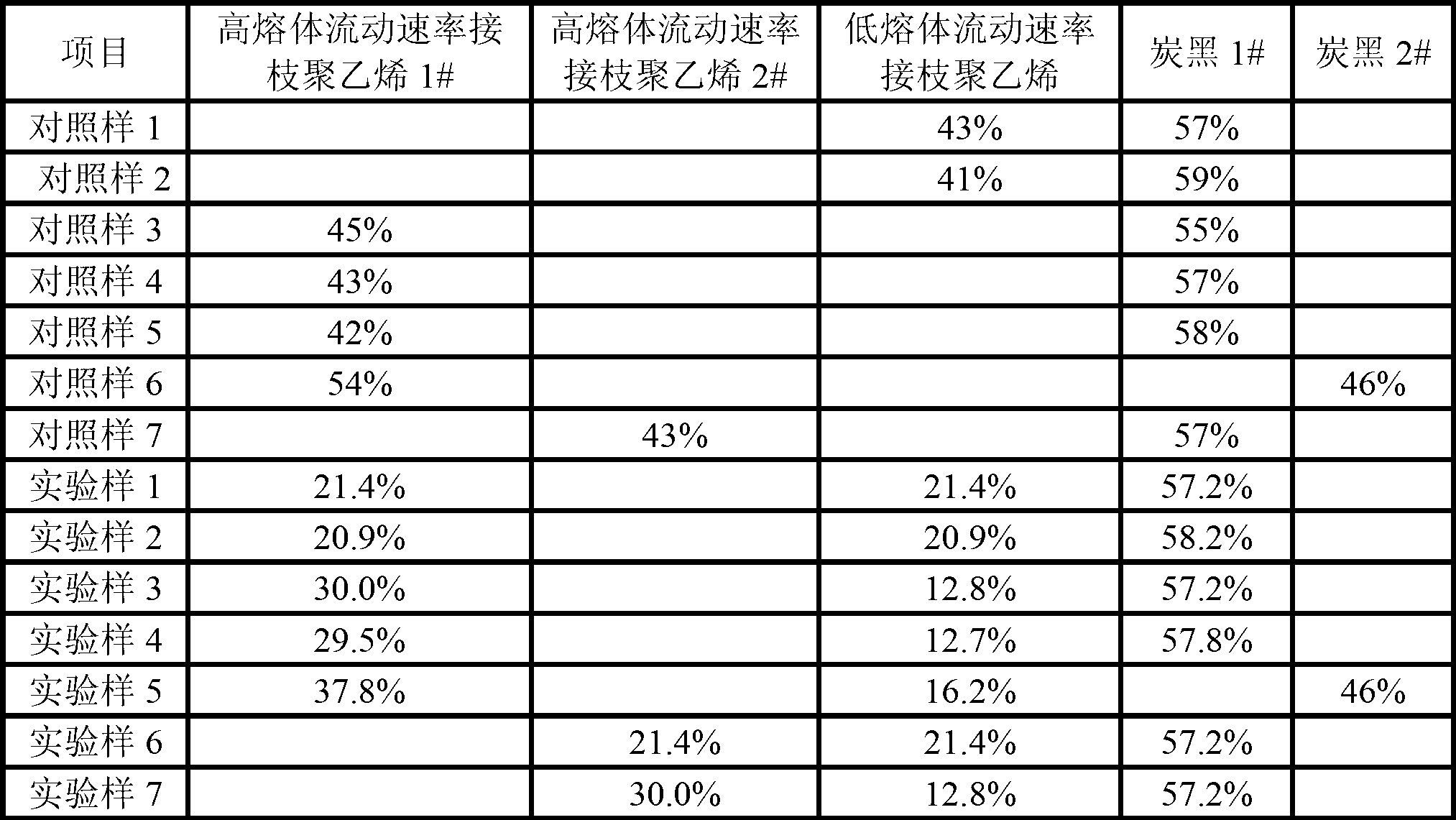

[0058] Table 2 Sample formula table (the following substances are weight percentages)

[0059]

[0060] 2. Experimental method

[0061] According to the raw material composition and the proportioning ratio given in Table 2, the core material of positive temperature coefficient thermistor element is prepared, and the specific steps are as follows:

[0062] 1) Grinding the granular polymer, and premixing the powdered polymer with conductive carbon black according to the formula in Table 2;

[0063] 2) Melt and mix the pre-mixed raw materials through the twin-screw, the temperature of each zone of the twin-screw is 180~210°C, the speed of the twin-screw is 80-200 rpm, and then ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com