Method for preparing powdery Alpha-olefin sulfonate and preparation device

An olefin sulfonate, powdery technology is applied in the field of preparation of surfactants, which can solve the problems of high energy consumption, inconvenient packaging and use, no industrialized production, etc., and achieves low equipment requirements, easy maintenance, and equipment volume and size. The effect of reduced processing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

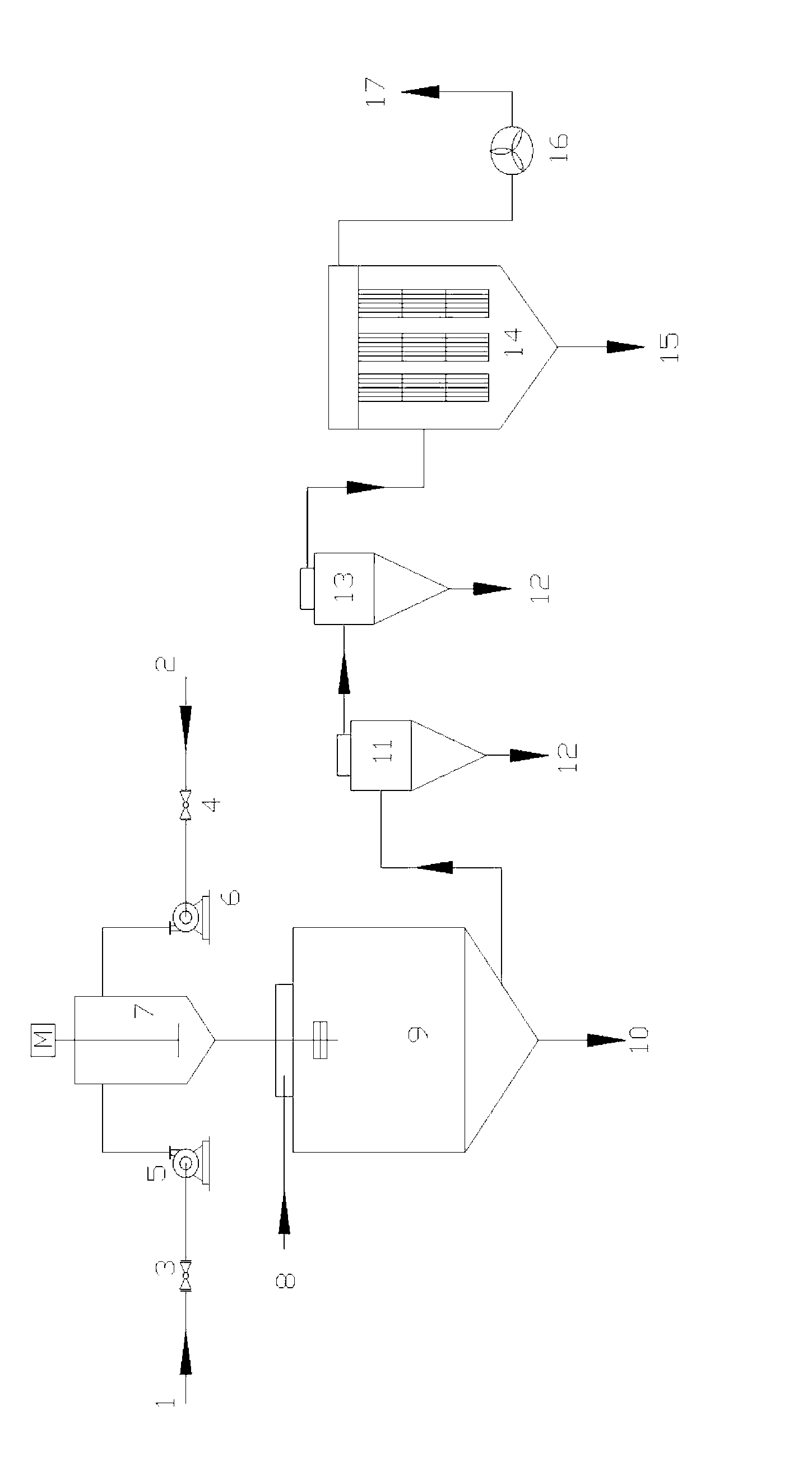

Image

Examples

Embodiment 1

[0056] The production of powdered AOS is carried out on the LPG-100 centrifugal spray drying tower; the centrifugal spray drying tower is turned on, and the heated dry air is introduced. The inlet temperature of the dry air is 300°C, and the flow rate is 1000m 3 / min, start the stirring of the mixing and stirring tank, the AOS acid ester after sulfonation and aging is adjusted to a flow rate of 200kg / h through a pneumatic regulating valve, and is pumped into the mixing and stirring tank through a metering pump, and at the same time, the liquid caustic soda is adjusted to a flow rate of 100kg / h through a pneumatic regulating valve h, enter the mixing tank through the metering pump, and then feed steam to heat the material in the mixing tank. The heating temperature is 190 ° C, and the concentration of liquid caustic soda is 32%. After the mixed material stays for 30 minutes, open the mixing tank Bottom valve, the material enters the centrifugal spray drying tower for centrifugal...

Embodiment 2

[0059] Powdery AOS production is carried out on the LPG-100 centrifugal spray drying tower; the centrifugal spray drying tower is turned on, and heated dry air is introduced. The inlet temperature of the dry air is 350°C, and the flow rate is 800m 3 / min, start the stirring of the mixing and stirring tank, the AOS ester after sulfonation and aging is adjusted to a flow rate of 170kg / h through a pneumatic regulating valve, and is pumped into the mixing and stirring tank through a metering pump, and at the same time, the liquid caustic soda is adjusted to a flow rate of 120kg / h through a pneumatic regulating valve h, enter the mixing tank through the metering pump, and at the same time, feed steam to heat the material in the mixing tank. The heating temperature is 170°C, and the concentration of liquid caustic soda is 25%. After the mixed material stays for 20 minutes, open the mixing tank Bottom valve, the material enters the centrifugal spray drying tower for spray drying; the ...

Embodiment 3

[0062] Powdered AOS production is carried out on the YPG-100 pressure spray drying tower, the pressure spray drying tower is turned on, and heated dry air is introduced. The inlet temperature of the dry air is 220°C and the flow rate is 700m 3 / min, start the stirring of the mixing tank, the AOS acid ester after sulfonation and aging is adjusted to a flow rate of 200kg / h through a pneumatic control valve, and is pumped into the mixing tank through a metering pump, and at the same time, the liquid caustic soda is adjusted to a flow rate of 80kg / h through a pneumatic control valve h, enter the mixing tank through the metering pump, and at the same time, feed steam to heat the material in the mixing tank. The heating temperature is 180°C, and the concentration of liquid alkali is 42%. After the mixed material stays for 25 minutes, open the mixing tank Bottom valve, the material enters the pressure spray drying tower for spray drying; the mixed air flow enters the first-stage cyclo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com