Flexible graphene composite film and preparation method thereof

A flexible graphite and composite thin film technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems that limit the smooth transport of electrons and holes in graphene, the difficulty of graphene electrodes to be used alone, and the difficulty in large-scale production, etc. problems, to achieve the effect of easy control of experimental conditions, good uniformity of surface structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of graphene / small molecule composite films with electron-withdrawing groups

[0040] 1) The PET substrate is ultrasonically cleaned 4-5 times in advance with deionized water, acetone and isopropanol to remove oil and impurities on the surface, and then the surface is treated with oxygen plasma to improve the adhesion of the substrate.

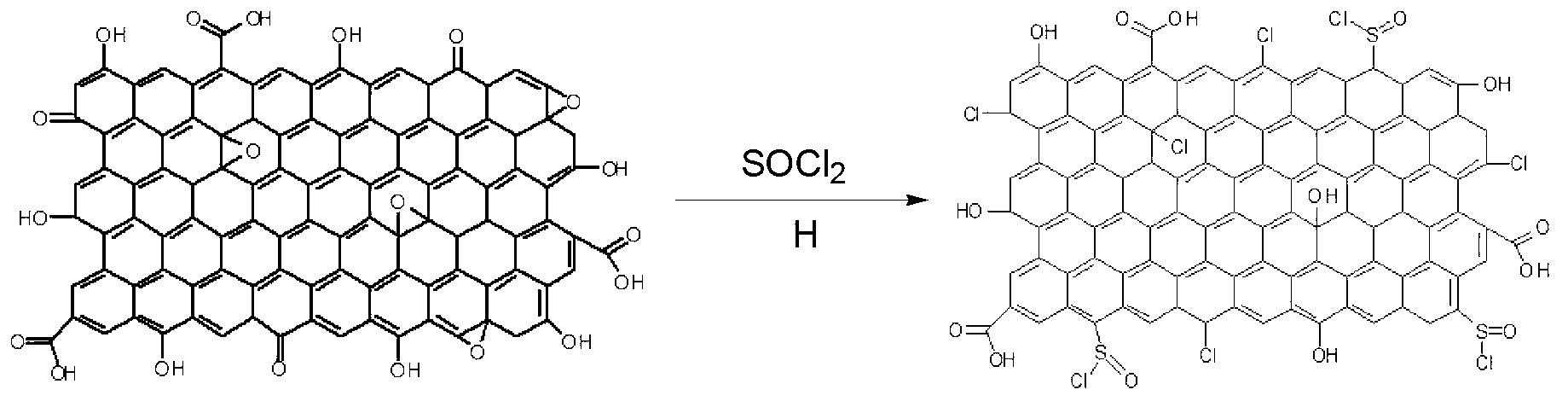

[0041] 2) After treating the 1mg / mL graphene oxide solution with a small amount of isocyanate, add 0.1mg / mL SOCl 2 The solution was stirred for 24h in a nitrogen atmosphere, and the reaction process was as follows figure 1 shown.

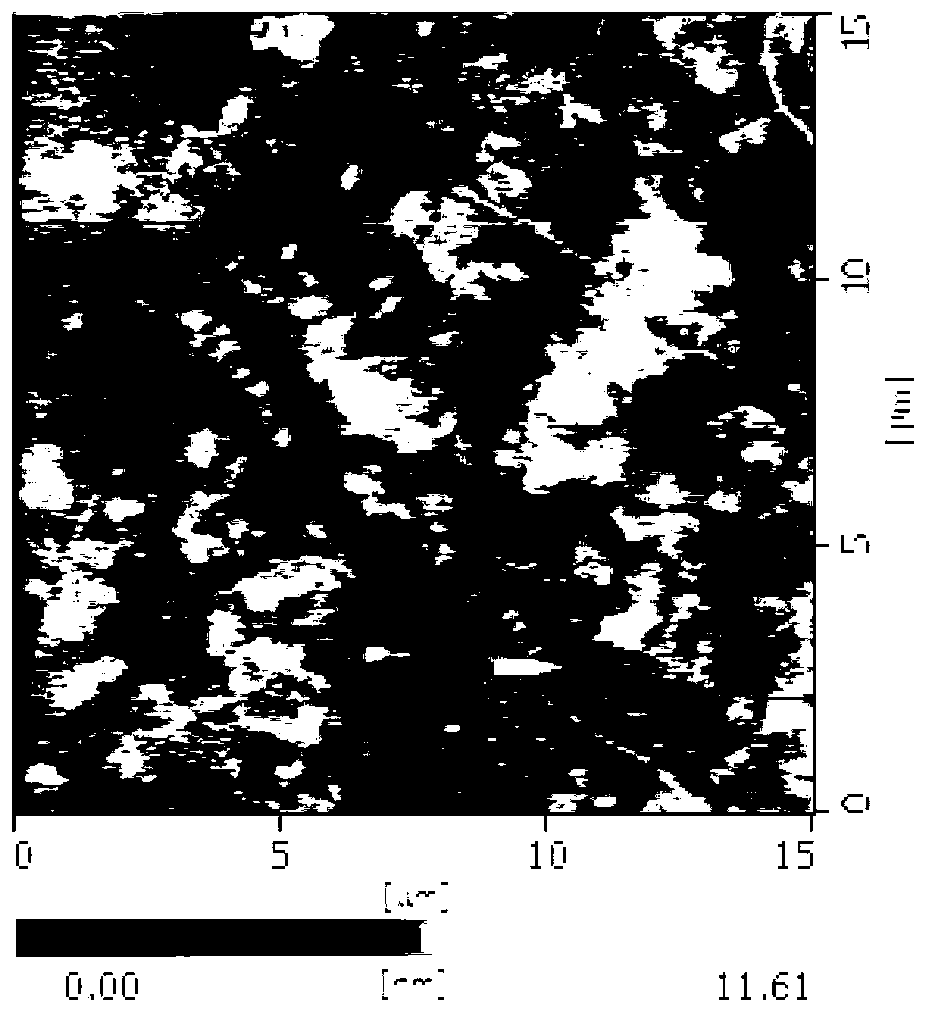

[0042] 3) Spin-coat the obtained mixed solution on the surface of the PET substrate to form a uniform film, control the speed at 3000 rpm, rotate for 15 seconds, dry in a vacuum oven, and repeat the above steps 5-6 times.

[0043] 4) Immerse the obtained substrate in a hydrazine hydrate solution for full reduction, then take out the substrate, heat it to 100-150°C at a rate of 10°C / min under a ni...

Embodiment 2

[0046] Preparation of graphene / polymer composite films with electron-withdrawing groups

[0047] 1) The PET film substrate is ultrasonically cleaned 4-5 times in advance with deionized water, acetone and isopropanol to remove oil and impurities on the surface, and then treated with oxygen plasma to improve the adhesion of the substrate.

[0048] 2) Fully reduce 1 mg / mL graphene with hydrazine hydrate at a volume ratio of 100:1, vacuum filter the obtained graphene reduction solution, wash it repeatedly with deionized water and acetone for 5-10 times, and then put it in a vacuum oven Fully dry at 100°C for 5 hours to obtain reduced graphene powder; dissolve the reduced graphene powder in DMF solution for ultrasonic treatment, after the solution is treated with a small amount of isocyanate, add a small amount of epoxy acrylic resin, and stir under nitrogen atmosphere More than 36 hours.

[0049] 3) Immerse the substrate in the above mixture, pull it out after 5 seconds at a pull...

Embodiment 3

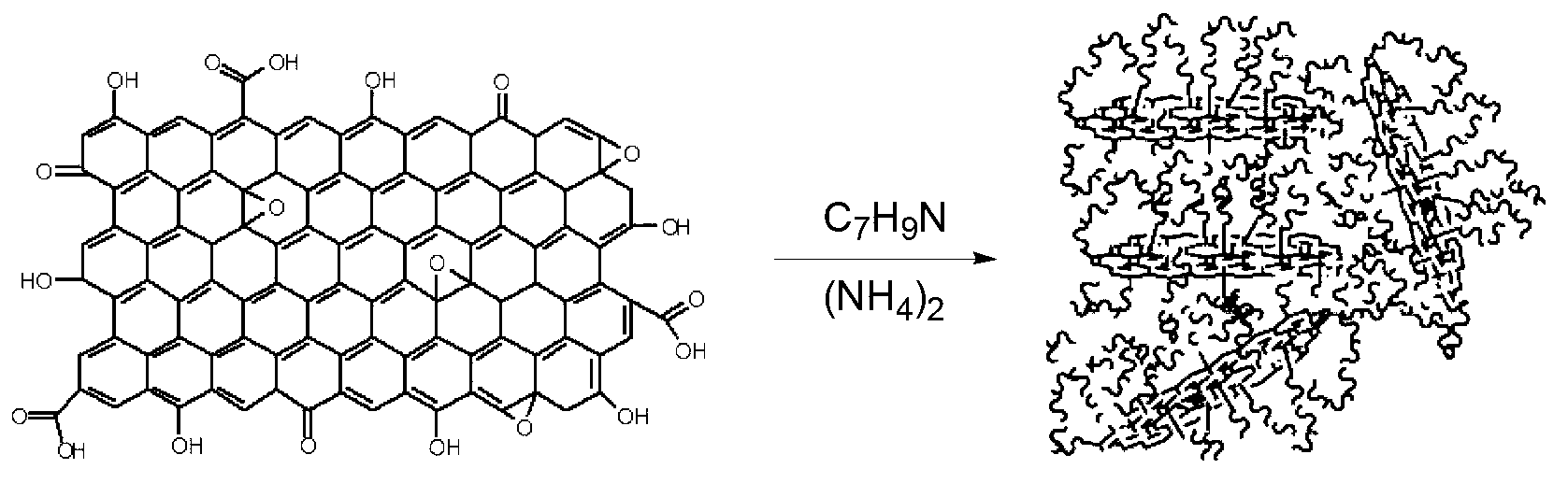

[0053] Preparation of Graphene / Small Molecule Composite Films with Electron Donating Groups

[0054] 1) The PET film substrate is ultrasonically cleaned 4-5 times in advance with deionized water, acetone and isopropanol to remove oil and impurities on the surface, and then treated with oxygen plasma to improve the adhesion of the substrate.

[0055] 2) After the 1 mg / mL graphene oxide solution was treated with a small amount of isocyanate, it was passivated with 70% nitric acid, and then 0.1 mg / mL isopropanol aqueous solution was added and stirred in a nitrogen atmosphere for 48 h.

[0056] 3) Spin-coat the obtained mixed solution on the surface of the PET substrate to form a uniform film, control the speed at 3000 rpm, rotate for 15 seconds, dry in a vacuum oven, and repeat the above steps 5-6 times.

[0057] 4) Immerse the obtained substrate in the ethylenediamine solution for 1 hour, then take out the substrate, and heat it to 100-300° C. at a speed of 10° C. / min under a ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com