Steel-wire belt cut-off device for square-section bead ring

A technology of cutting device and traveler, applied in the field of steel belt devices, can solve the problems of frequent movements, heavy maintenance work, large impact noise, etc., and achieve the effect of eliminating potential safety hazards and saving equipment operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

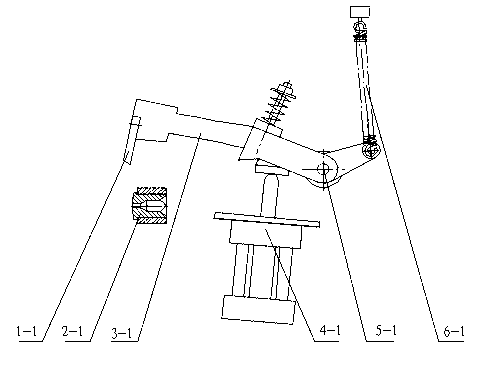

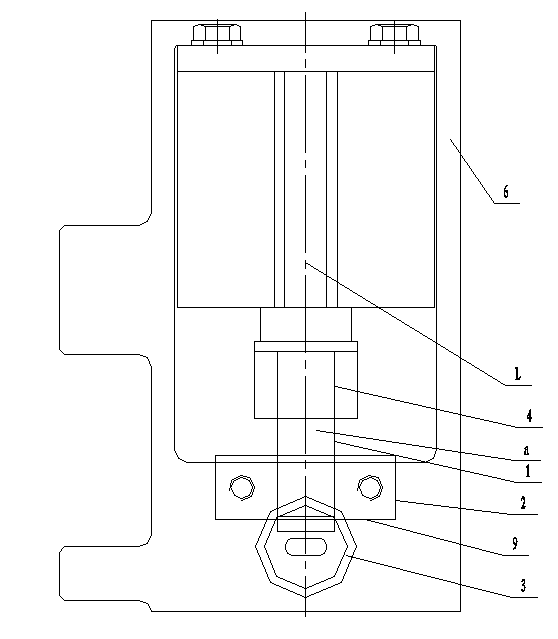

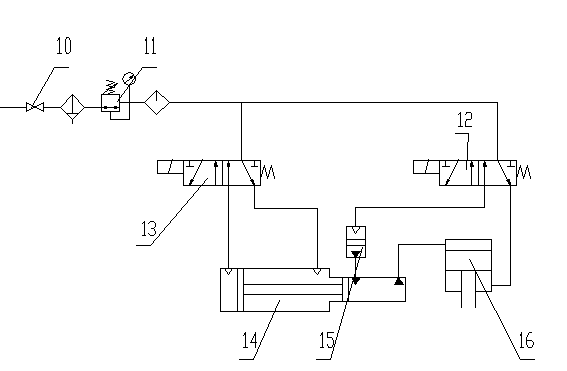

[0027] Such as figure 2 , image 3 and Figure 4 A steel wire cutting device for a square-section traveler is shown, which consists of two parts: an actuator and a gas-hydraulic power system. The actuator consists of a mounting frame 6, a machine nozzle 3, a cutter 1, a hydraulic cylinder 5, and a cutter joint 4 The machine nozzle 3 is arranged at the bottom of the installation frame 6, the hydraulic cylinder 5 is arranged at the top of the installation frame, the cutter 1 is installed on the piston rod 8 of the hydraulic cylinder through the cutter joint 4, and the cutter blade 9 and the cutter The plane a where the knife is located coincides with the plane passing through the center line L of the piston rod. The cutter blade 9 corresponds to the outlet of the machine nozzle. The gas-hydraulic power system is connected to the hydraulic cylinder 5. The cutter at the lower part of the piston rod cuts off the steel wire coming out of the nozzle. The installation frame of hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com