UHMWPE (Ultra High Molecular Weight Polyethylene) artificial joint with surface wear-resistant layer and preparation method of same

An ultra-high molecular weight, artificial joint technology, applied in the field of ultra-high molecular weight polyethylene artificial joints and preparation, can solve the problems of unguaranteed material mechanical properties, weakened bearing capacity of joint cups, and material mechanical properties. Replacement frequency, good toughness and mechanical properties and anti-aging properties, the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

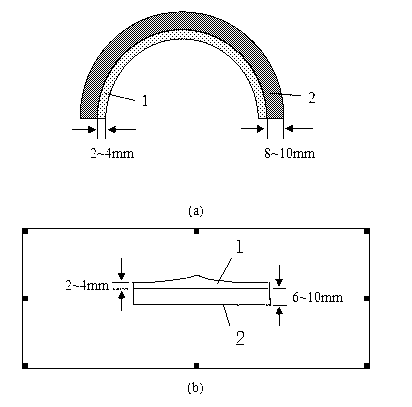

[0022] combine figure 1 , the artificial joint of the present invention consists of a wear-resistant layer 1 and a matrix 2, and its preparation method comprises the following steps:

[0023] (1) Vacuum packaging the composite of ultra-high molecular weight polyethylene (medical grade, molecular weight greater than 2 million) and nanoparticles (composite powder or composite powder formed by vacuum hot pressing). The mass fraction of nanoparticles is 0-10%. Nanoparticles are inorganic nanoparticles whose surface is modified by a coupling agent, such as nano-hydroxyapatite, nano-alumina, zirconia or silica, etc. The composite powder is blended by ball milling Preparation, the ball milling speed is 300rpm, and the time is 2 hours;

[0024] (2) Gamma ray irradiation is performed on the vacuum-packed complex, the gamma ray is produced by a cobalt-60 ray source, and the selected irradiation dose is less than or equal to 200kGy;

[0025] (3) The vacuum-irradiated composite and pur...

Embodiment 1

[0027] Example 1: Vacuum irradiated pure ultra-high molecular weight polyethylene powder is selected, that is, the nanoparticle content is 0%.

[0028] The preparation process is as follows:

[0029] (1) Vacuum packaging of pure UHMWPE powder;

[0030] (2) Gamma ray irradiation is performed on the vacuum-packed powder, and the selected dose is 100kGy;

[0031] (3) The powder obtained by vacuum irradiation and the unirradiated pure ultra-high molecular weight polyethylene powder are layered into the mold, and the vacuum hot-pressing furnace is turned on to carry out vacuum hot-pressing on the material loaded into the mold. The specific parameters are: vacuum degree- 0.1MPa, pressure 10MPa, hot pressing temperature 150°C, holding time 1.5 hours. The prepared samples were tested on a three-station knee joint wear tester under the conditions of 25% calf serum lubrication, a load of 1062N, a CoCrMo alloy on the grinding surface, and a surface roughness of 0.1 μm. The wear rate o...

Embodiment 2

[0032] Example 2: Vacuum irradiated ultra-high molecular weight polyethylene composite powder is selected. The preparation process is as follows:

[0033] (1) Vacuum packaging ultra-high molecular weight polyethylene powder containing 1% nano-hydroxyapatite particles;

[0034] (2) Gamma ray irradiation is performed on the vacuum-packed powder, and the selected dose is 100kGy;

[0035](3) The powder obtained by vacuum irradiation and the unirradiated pure ultra-high molecular weight polyethylene powder are layered into the mold, and the vacuum hot-pressing furnace is turned on to carry out vacuum hot-pressing on the material loaded into the mold. The specific parameters are: vacuum degree- 0.1MPa, pressure 15MPa, hot pressing temperature 200°C, holding time 2 hours. The thickness of the matrix of the demoulded artificial hip joint socket sample is 8-10 mm, and the thickness of the wear-resistant layer is 2-4 mm. The prepared artificial hip joint socket samples were tested on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com