Reflective material

A technology of reflective materials and resin layers, applied in the field of reflective materials, can solve the problems of film deterioration, reduced light reflectivity of reflective films, uneven brightness, etc., and achieve the effect of ensuring bending resistance and heat resistance, and excellent light diffusivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

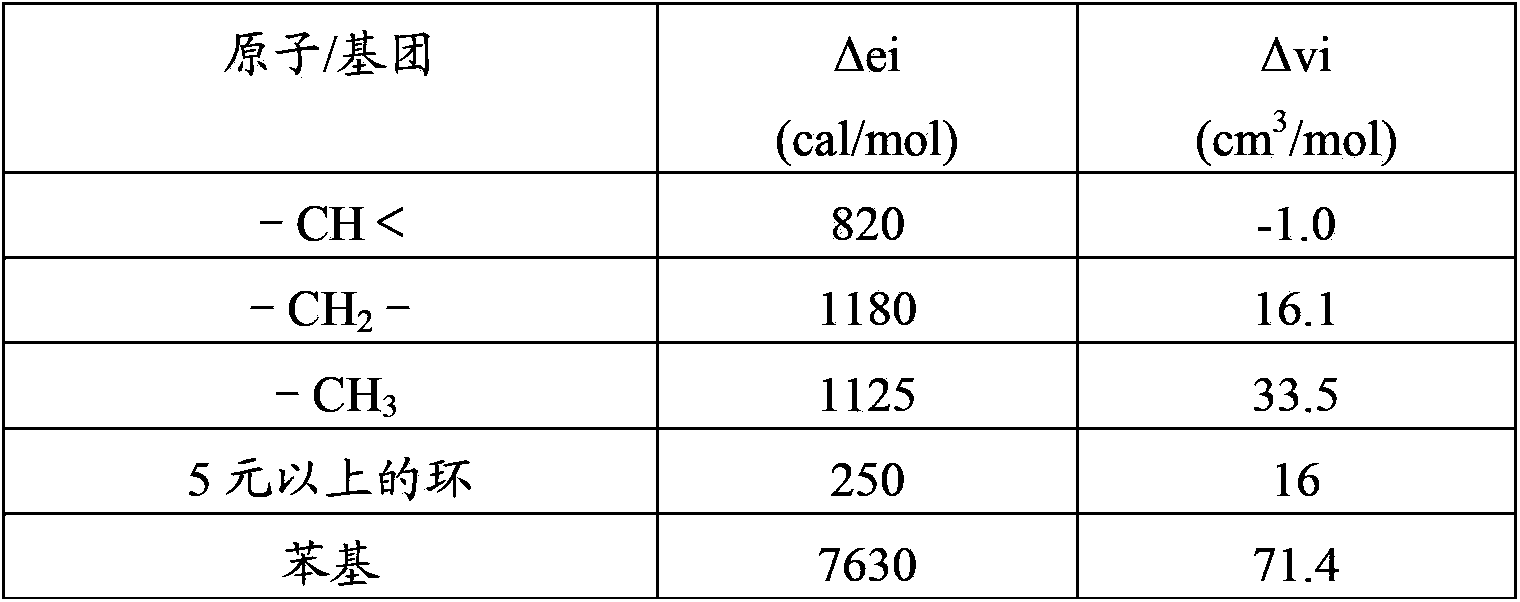

Method used

Image

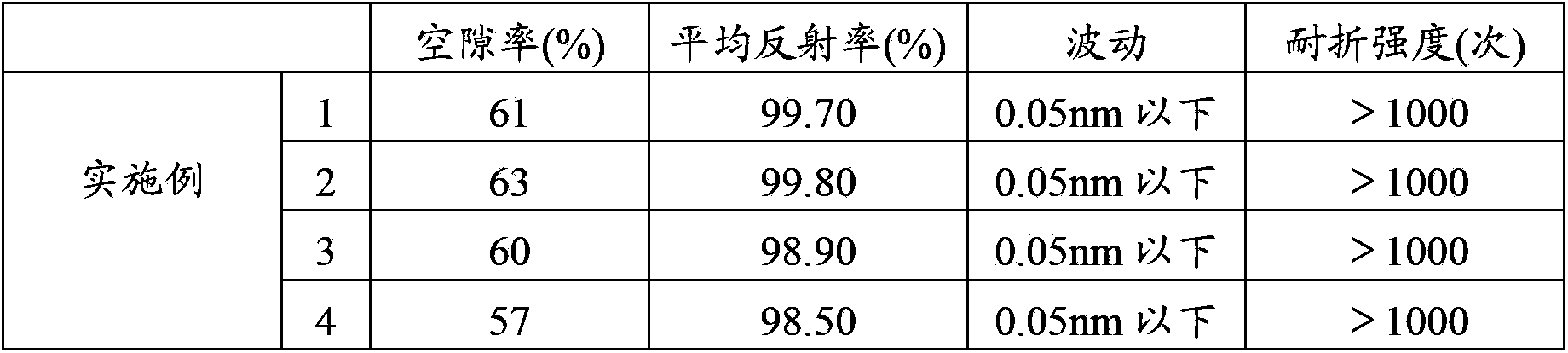

Examples

Embodiment 1

[0215] (Preparation of resin composition A for resin layer (A))

[0216] Polypropylene resin (manufactured by Nippon Polypropylene Co., Ltd., trade name "NOVATEC PP FY6HA", density (JIS K7112): 0.9 g / cm 3 , MFR (230°C, 21.18N, JIS K-7210): 2.4g / 10min) particles and titanium oxide (manufactured by KRONOS, trade name "KRONOS2230", density 4.2g / cm 3 , rutile titanium oxide, Al, Si surface treatment, TiO 2 Content 96.0%, manufacturing method: chlorine method) mixed in the mass ratio of 50:50, and pelletized using the twin-screw extruder after heating at 270 degreeC, and the resin composition A was produced.

[0217] (Preparation of resin composition B for resin layer (B))

[0218] Amorphous cycloolefin resin A (manufactured by Japan Zeon Co., Ltd., trade name "ZEONOR1430R", density (ASTMD792): 1.01g / cm 3 , glass transition temperature Tg (JIS K7121): 133°C, SP value: 7.4), amorphous cycloolefin resin B (manufactured by Zeon Co., Ltd., trade name "ZEONOR1060R", density (ASTMD792...

Embodiment 2

[0225] In the preparation of the resin composition B of Example 1, particles of an amorphous cycloolefin resin A (manufactured by Nippon Zeon Co., Ltd., trade name "ZEONOR1430R", SP value: 7.4) and polypropylene resin (Nippon Poly Propylene Co., Ltd., trade name "NOVATEC PPEA9", SP value: 8.0) particles were mixed at a mass ratio of 75:25, and in the production of the reflective material of Example 1, the obtained laminated sheet was heated at temperature 138° C. was carried out in the MD for 2-fold roll stretching, and further at 138° C. in the TD for 3-fold tenter stretching, thereby carrying out biaxial stretching. Except for the above two points, the same operation as in Example 1 was obtained. A reflective material (sample) having a thickness of 228 μm (resin layer (A): 190 μm, resin layer (B): 19 μm, lamination ratio A:B=5:1) was prepared. The same evaluation as in Example 1 was performed about the obtained reflective material.

Embodiment 3

[0227] (Preparation of resin composition A for resin layer (A))

[0228] Polypropylene resin (manufactured by Nippon Polypropylene Co., Ltd., trade name "NOVATEC PP FY6HA", density (JIS K7112): 0.9 g / cm 3 , MFR (230°C, 21.18N, JIS K-7210): 2.4g / 10min, SP value: 8.0) particles and titanium oxide (manufactured by KRONOS, trade name "KRONOS2230", density 4.2g / cm 3 , rutile titanium oxide, Al, Si surface treatment, TiO 2 Content 96.0%, manufacturing method: chlorine method) mixed in the mass ratio of 50:50, and pelletized using the twin-screw extruder after heating at 270 degreeC, and the resin composition A was produced.

[0229] (Preparation of resin composition B for resin layer (B))

[0230] Amorphous cyclic olefin resin C (manufactured by Japan Zeon Co., Ltd., trade name "ZEONOR RCY50", a hydrogenated product of a ring-opened polymer of cyclic olefins, density (ISO1183): 1.01 g / cm 3 , MFR (230°C, 21.18N, JIS K7210: 1.2g / 10min, glass transition temperature Tg (JIS K7121): 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com