Polypropylene compound, its preparation method and its application

A technology of polypropylene and composites, which is applied in the field of polypropylene composites, can solve the problems of decreased toughness of materials, decreased toughness of polypropylene, large polarity difference, etc., and achieves high toughness, no reduction in rigidity, and small particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

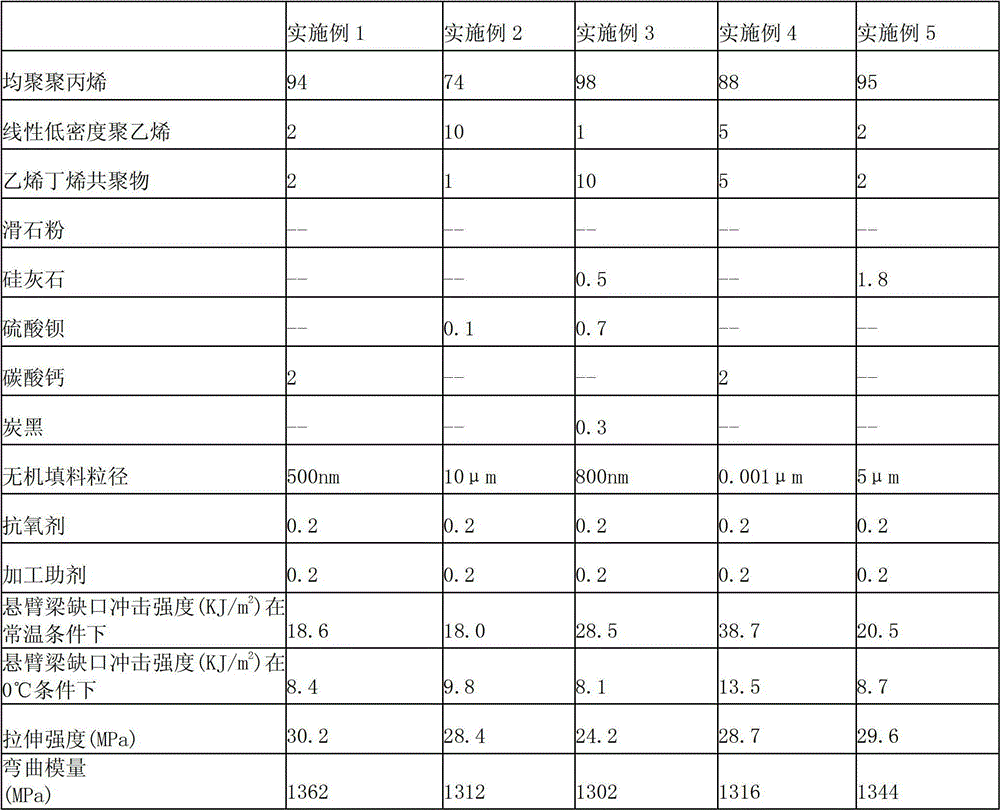

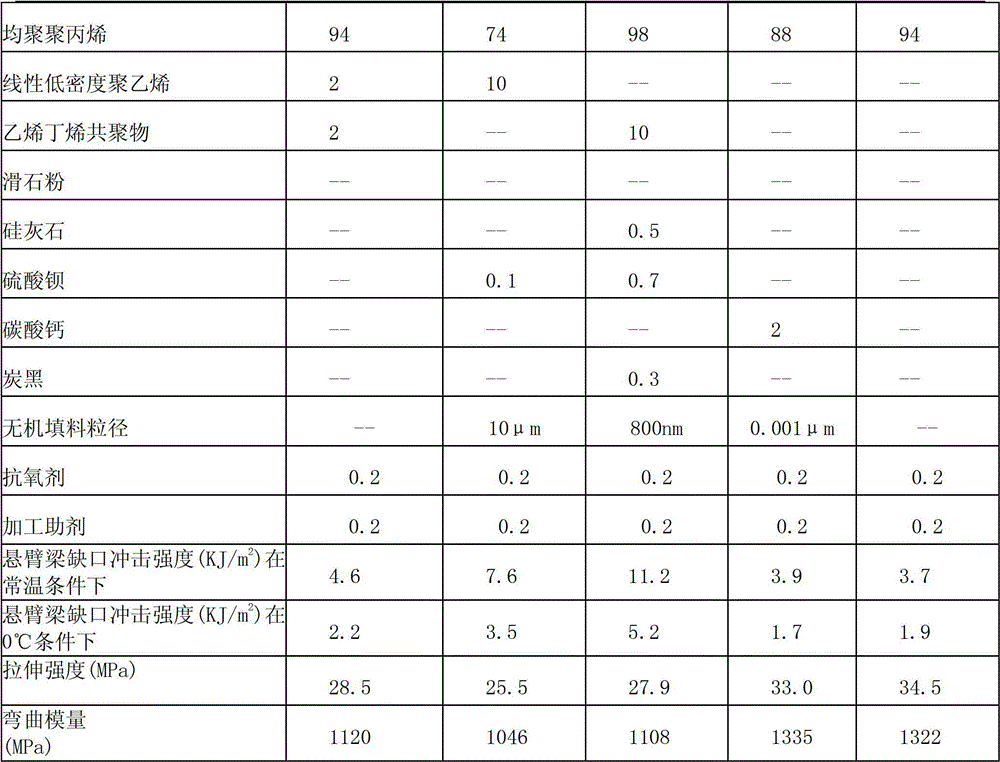

Embodiment 1-5

[0062] Homopolypropylene with a melt index of 10g / 10min, linear low-density polyethylene with a melt index of 10g / 10min, polyolefin elastomer with a melt index of 10g / 10min, inorganic fillers with a particle size of 100nm-10μm, antioxidant The weight parts of each embodiment components such as agent 1010 and processing aid zinc stearate etc. are mixed by the ratio shown in table 1, join in the extrusion of twin-screw extruder, the temperature setting of extruder is 230 ℃, with a rotation speed of 50 rpm, stirring, extruding after reaction, cooling, and cutting into pellets to obtain polypropylene composites. The polyolefin elastomer described in Examples 1-5 can be an ethylene-butylene copolymer, and the inorganic filler includes at least one of talcum powder, calcium carbonate, mica, wollastonite, and barium sulfate. Refer to Table 1 for the particle size of the inorganic filler in the components of each of the above examples, and its performance parameters are shown in Table...

Embodiment 6-10

[0072] Mix the components of copolymerized polypropylene, polyethylene, polyolefin elastomer, inorganic filler with a particle size between 100-200nm, antioxidant 1010 and processing aid zinc stearate, etc., and then add them to the twin-screw extruder Extruded in the extruder, the temperature of the extruder was set at 210°C, the rotating speed was 300 rpm, stirred, extruded after reaction, then cooled, and pelletized to obtain a polypropylene compound. The parts by weight of the components are shown in Table 3. The melt indices of the above-mentioned copolymerized polypropylene, polyethylene, and polyolefin elastomers and the particle diameters of the inorganic fillers are shown in Table 3. The performance parameters of polypropylene composites are shown in Table 3. The polyolefin elastomer described in Examples 6-10 may be an ethylene butene copolymer. The polyethylene may be a mixture of low density polyethylene and high density polyethylene. The inorganic filler includ...

Embodiment 11-15

[0077] After mixing homopolypropylene, low density polyethylene, polyolefin elastomer, inorganic filler with a particle size between 0.5-0.8 μm, antioxidant 1010 and processing aid zinc stearate, add it to Extruded in a twin-screw extruder, the temperature of the extruder was set at 190°C, the rotating speed was 400 rpm, stirred, reacted, extruded, then cooled, and pelletized to obtain a polypropylene compound. The parts by weight of the components are shown in Table 3, and the melt indices of the above-mentioned copolymerized polypropylene, polyethylene, and polyolefin elastomers are all 10 g / 10 min, and the particle diameters of the inorganic fillers are shown in Table 4. The performance parameters of polypropylene composites are shown in Table 4. The polyolefin elastomer in Examples 11-15 may be a mixture of both ethylene octene copolymer and ethylene butene copolymer.

[0078] Table 4

[0079]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com