Polyester film for protecting rear surface of solar cell

A back protective film and solar cell technology, which is applied in polyester coatings, circuits, photovoltaic power generation, etc., can solve the problems of insufficient hydrolysis resistance, reduced power generation performance of solar cell modules, and uneconomical problems, and achieve excellent resistance to detachment Laminarity, good protection function, and the effect of suppressing the reduction of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

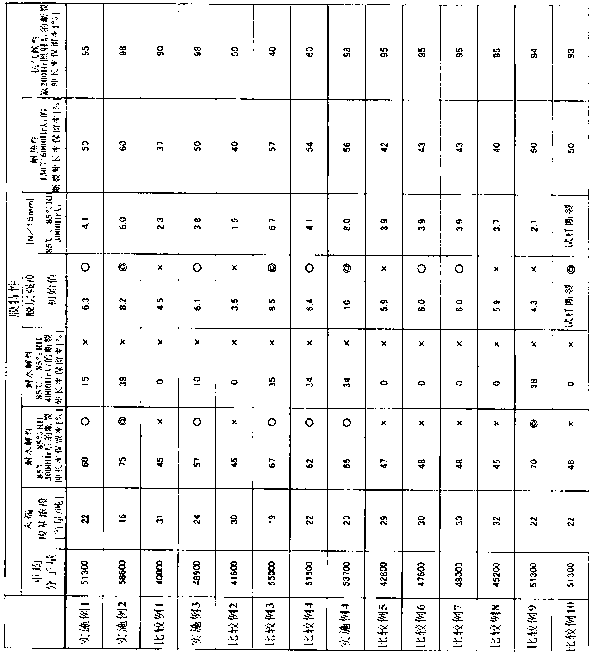

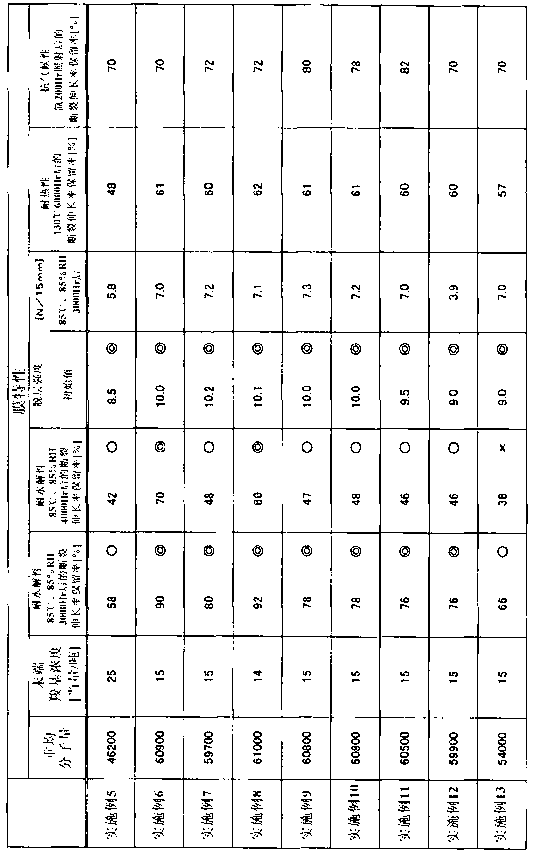

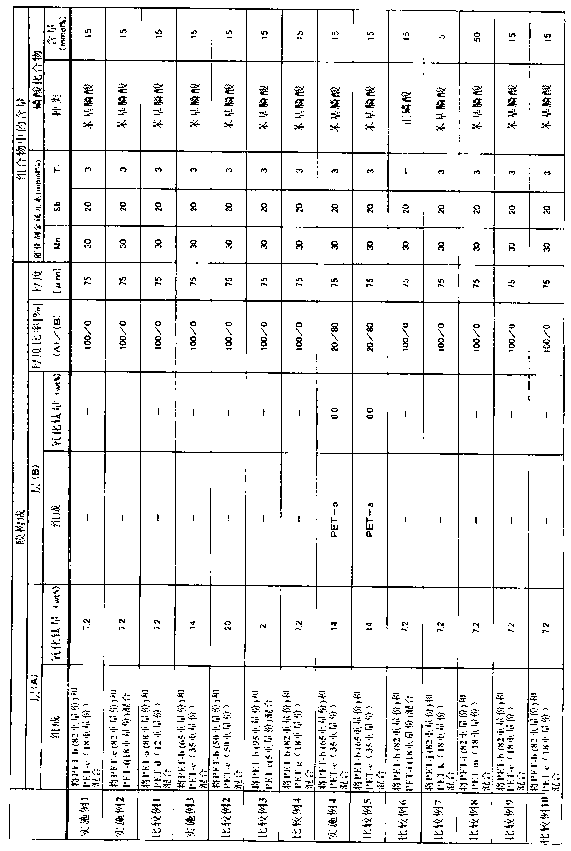

[0157] Examples are given below to describe the present invention in detail. The evaluation method is as follows.

[0158] (1) Film thickness

[0159] The thickness of the film sample was measured at 10 locations with an electric micrometer (K-402B manufactured by Anritsu), and the average value was used as the thickness of the film.

[0160] (2) Intrinsic viscosity number (η)

[0161] The solution viscosity measured at a temperature of 35° C. after dissolving in a mixed solvent of phenol:tetrachloroethane at a weight ratio of 6:4 was used, and a value calculated by the following formula was used.

[0162] ηsp / C=[η]+K[η] 2 ?C

[0163] Among them, ηsp=(solution viscosity / solvent viscosity)-1, C is the dissolved polymer weight per 100ml of solvent (g / 100ml), and K is Huggins constant. In addition, the solution viscosity and the solvent viscosity were measured using an Ostwald viscometer. The unit is expressed in [dl / g].

[0164] (3) Weight average molecular weight

[0165]...

reference example 11)

[0237] (Reference Example 11) Production of polyethylene terephthalate (PET-n)

[0238] 85% by weight of the polymer (PET-b) obtained in Reference Example 2 and 15% by weight of aromatic polycarbodiimide "Stabaxol P100" manufactured by Lan Chemie Co., Ltd. were mixed, and supplied to a twin-screw kneader. Melting at ℃. The melt-kneaded polyester composition was formed into strands, discharged into water, and fragmented by a cutter. Call it PET-n.

Embodiment 1~3

[0240] Polyester raw materials were mixed in the compounding ratio shown in Table 1, dried at 180°C for 3 hours with a rotary vacuum dryer, supplied to an extruder, melted and extruded at 285°C, and molded by a slotted die into flaky. Further, the sheet was cooled and solidified with a cooling drum with a surface temperature of 20°C to obtain an unstretched film, which was stretched 3.4 times in the longitudinal direction (longitudinal direction) at 100°C, and cooled with a set of rolls at 25°C. Next, the longitudinally stretched film was introduced into a tenter while holding both ends of the longitudinally stretched film with clips, and stretched 3.7 times in the direction perpendicular to the length (transverse direction) in an atmosphere heated to 130°C. Then heat-fix in an atmosphere heated to 222°C for 15 seconds in a tenter, reduce the width by 4.0% in the lateral direction, then subtract both ends, and relax at a relaxation rate of 2.5% in the longitudinal direction T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com