Synthetic leather article and method for preparing the same

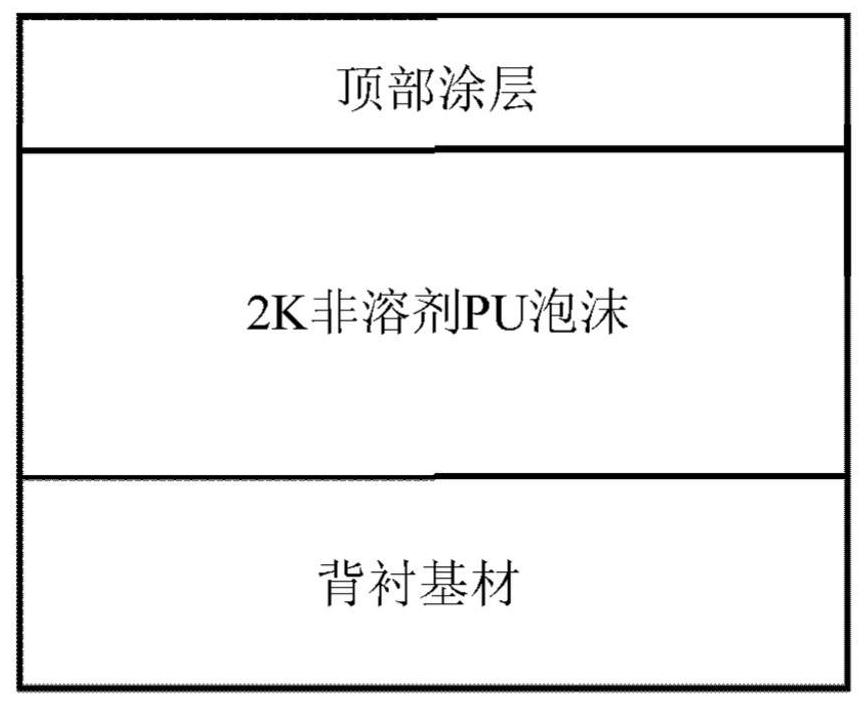

A technology for synthetic leather and products, applied in synthetic resin layered products, chemical instruments and methods, layered products, etc., to achieve the effect of excellent delamination resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0088] Some embodiments of the invention will now be described in the following examples, in which all parts and percentages are by weight unless otherwise indicated.

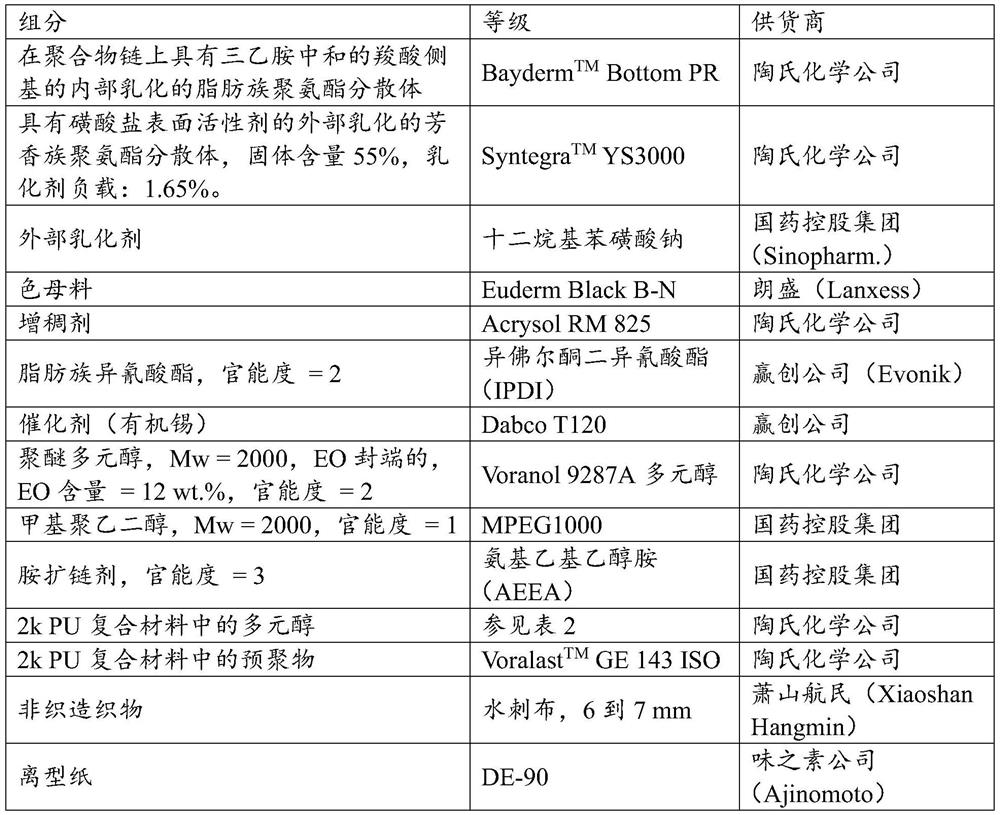

[0089] Information on the raw materials used in the examples is listed in Table 1 below:

[0090] Table 1. Raw materials

[0091]

[0092] By adding the isocyanate prepolymer shown in Table 1 (Voralast TM GE 143ISO) was combined with the raw materials listed in Table 2 (ie, component (Bii)) to prepare 2K non-solvent PU foam.

[0093] Table 2. Raw materials used in 2K PU composites (component (Bii))

[0094]

example 1

[0096] In this example, a synthetic leather was prepared by directly adhering an externally emulsified aliphatic polyurethane dispersion as a skin layer on a 2k PU foam layer, and a high peel strength was achieved.

[0097] 1) Preparation of isocyanate prepolymer of polyurethane particles in PUD:

[0098] Voranol 9287A (70 g) and MPEG1000 (2 g) were charged into a 250 ml three-necked flask and dehydrated at 110° C. and 76 mmHg vacuum for one hour, and then naturally cooled to about 73° C. IPDI (28 g) was poured into the dehydrated polyol mixture at about 73°C under nitrogen flow and mechanical stirring. Catalyst T120 (0.03 g) was then added to the reactants. The reaction was continued at about 73°C for one hour, and then the temperature was raised to about 83°C to continue the reaction for an additional 2.5 hours. The product (prepolymer) was packaged in a plastic bottle and sealed and stored under nitrogen protection. NCO% was measured to be 7.0 wt%.

[0099] 2) Preparati...

example 2

[0107] In this example, a synthetic leather was prepared by directly adhering an externally emulsified aromatic polyurethane dispersion as a skin layer on a 2k PU foam layer, and a high peel strength was achieved.

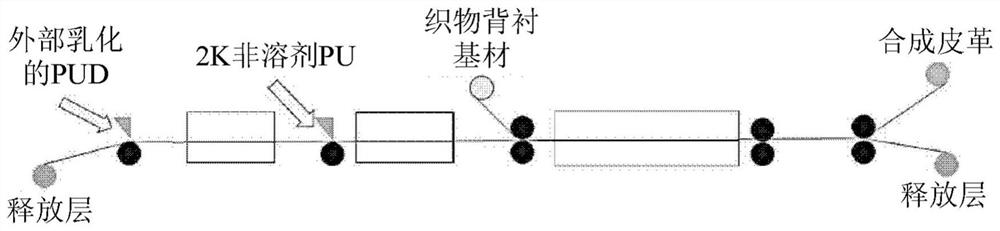

[0108] 1) Manufacture of synthetic leather

[0109] With 5g of color masterbatch and 1g of RM825 thickener, 94g of externally emulsified aromatic PUD, Syntegra YS3000 provided by Dow Chemical Company was formulated and mixed at 2500rpm for 4.5 minute. The formulated PUD was coated on release paper to a wet film thickness of 150 μm. The coated release paper was dried in an oven at 120° C. for 5 minutes. The release liner with the dry PU skin was removed from the oven and allowed to cool to ambient temperature.

[0110] The formulated 2k PU composite with the formulation of the polyol formulation and Voralast*GE 143ISO in Table 2 was coated on the dry PU skin opposite the release paper to a wet film thickness of 300 μm. Put the coated release paper in an oven at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com