White graphene modified polystyrene composite material and preparation method thereof

A technology of white graphene and polystyrene, which is applied in the field of white graphene modified polystyrene composite materials and its preparation, and can solve problems affecting mechanical strength and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

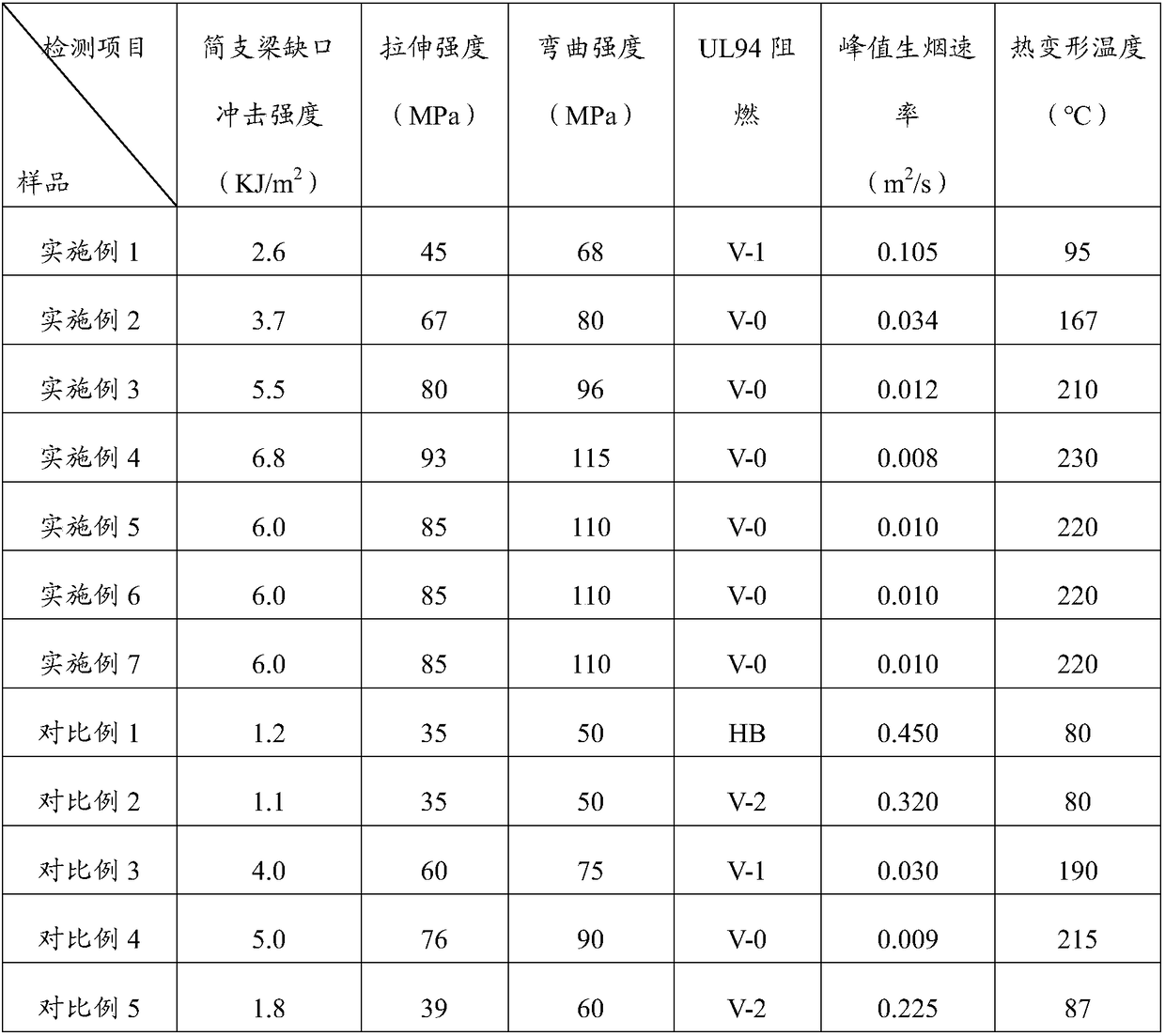

Examples

preparation example Construction

[0036] The present invention also provides the preparation method of above-mentioned white graphene modified polystyrene composite material, comprises the following steps:

[0037] Mix 90-110 parts of styrene, 0.5-10 parts of polymer-modified white graphene, 0.05-2 parts of flame retardant, 0.05-2 parts of antioxidant and 0.01-0.1 part of initiator, and mix well under the protection of inert gas , react at a temperature of 80°C-90°C for 3-6h to obtain a reaction solution, then mix the reaction solution with 100-150 parts of a dispersion medium, then pour it into an inert solvent, collect the resulting precipitate and dry it to obtain white graphene Modified polystyrene composite.

[0038]The order of adding the above materials is not particularly limited. In one embodiment, the initiator is added first, and then the remaining components are slowly added in an inert gas atmosphere to promote the complete reaction of the styrene monomer. In addition, after the polymerization re...

Embodiment 1

[0063] Step 1) Preparation of polymer-modified white graphene: Take 0.5 parts of white graphene powder and add it to a round-bottomed flask, and add 100 parts of distilled water to the round-bottomed flask, then ultrasonically disperse it, and add 0.1 parts to the round-bottomed flask Sodium lauryl sulfate, ultrasonically stirred at high speed to obtain lipophilic modified white graphene; after heating the lipophilic modified white graphene aqueous dispersion to 60°C, add 0.5 parts of initiator azobisisobutyronitrile, After stirring for 10 minutes, start to add 0.05 parts of styrene dropwise, and finish dropping in 0.5 hours. After the dropwise addition, keep warm for 0.5h until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 to 4 times, then wash with alcohol once, dry and grind in vacuum at 60°C to obtain pol...

Embodiment 2

[0067] Step 1) Preparation of polymer-modified white graphene: Take 2 parts of white graphene powder and add it to a round-bottomed flask, and add 100 parts of ethanol to the round-bottomed flask, then ultrasonically disperse it, and add 0.2 parts to the round-bottomed flask Sodium dodecyl sulfate, ultrasonically stirred at high speed to obtain lipophilic modified white graphene; after heating the lipophilic modified white graphene ethanol dispersion to 90°C, add 1 part of initiator ammonium persulfate, and stir for 15 minutes Start to add 0.5 parts of styrene dropwise, and finish dropping in 0.6h. After the dropwise addition, keep warm for 1 h until the reaction is complete. After the reaction is completed, adjust the pH value to 7 with ammonia water, quickly cool to room temperature, filter under reduced pressure, wash the filter cake with distilled water for 3 to 4 times, then wash with alcohol once, and vacuum dry and grind at 70°C to obtain polystyrene coating modificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com