Mordenite/SAPO-34 composite molecular sieve amination catalyst and method for preparing same

A SAPO-34 and composite molecular sieve technology, which is applied in the field of mordenite/SAPO-34 composite molecular sieve amination catalyst and its preparation, can solve the problems of difficult desorption, low low temperature activity, fast coking and the like, and achieves simplified preparation steps, The effect of high overall selectivity and high low temperature activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

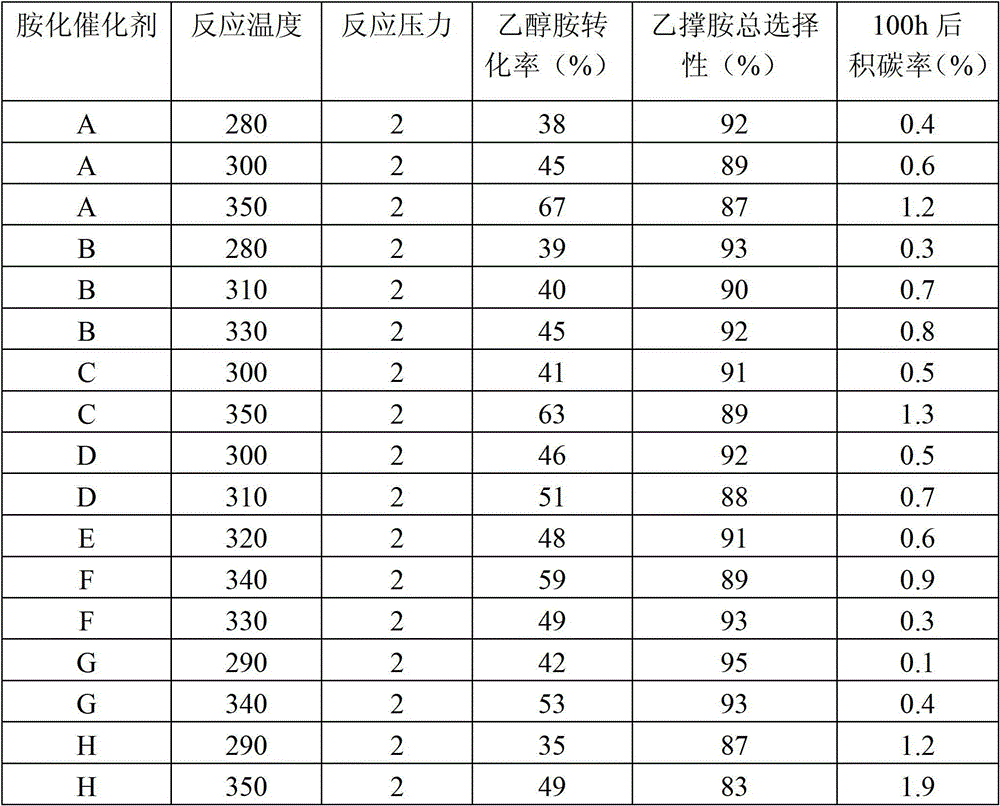

Examples

Embodiment 1

[0033] Mix 3.5g of pseudo-boehmite and 6g of deionized water at 60°C, slowly add 5.7g of orthophosphoric acid with a weight percentage of 85% and 0.05g of hydrofluoric acid dropwise, stir for 1h, then add 24g of silica sol, and stir for 1h , then drop 5 g of 4-hydroxypiperidine, adjust the pH of the mixture to 5-6, and keep stirring for 1 h; add SiO 2 / Al 2 o 3 5g of 20-80 mordenite molecular sieves, continuously stirred for 1h, mixed evenly, and aged for 1h; the mixture was hydrothermally crystallized at 130°C for 10h in a polytetrafluoroethylene-lined autoclave, and then heated to 180°C, Constant temperature hydrothermal crystallization for 24 hours, the product was filtered, washed with deionized water, dried at 120°C for 6 hours, and calcined at 500°C in air atmosphere for 2 hours to obtain mordenite / SAPO-34 composite molecular sieve;

[0034]Mix 80 g of mordenite / SAPO-34 composite molecular sieve, 15 g of titanium oxide, and 5 g of alumina evenly, granulate, press and s...

Embodiment 2

[0036] Embodiment 2 is substantially the same as the preparation process in Example 1, and the difference is that adopting 2.2g weight percent is 85% orthophosphoric acid, template agent morpholine is 1.2g, and deionized water is 5.2g, and prepared mordenite / SAPO-34 Composite Molecular Sieve Amination Catalyst B.

Embodiment 3

[0038] The preparation process of embodiment 3 is basically the same as that of embodiment 1, and the difference is that adopting 6.6g of orthophosphoric acid with a weight percentage of 85%, the templating agent 4-hydroxymethyl piperidine is 7.9g, and deionized water is 52g to prepare Mordenite / SAPO-34 composite molecular sieve amination catalyst C was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com