Method for forming copper Damascus structure

A patterning, sacrificial layer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of interlayer dielectrics and dielectric anti-reflection coatings that do not have a good polishing selection ratio, copper-metal mutual Reduce the thickness of the connection and the loss of the interlayer dielectric, so as to improve the lithography performance, reduce the standing wave effect, and reduce the loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Some typical embodiments embodying the features and advantages of the present invention will be described in detail in the description in the following paragraphs. It should be understood that the invention is capable of various changes in different examples without departing from the scope of the invention, and that the descriptions and illustrations therein are illustrative in nature rather than limiting the invention.

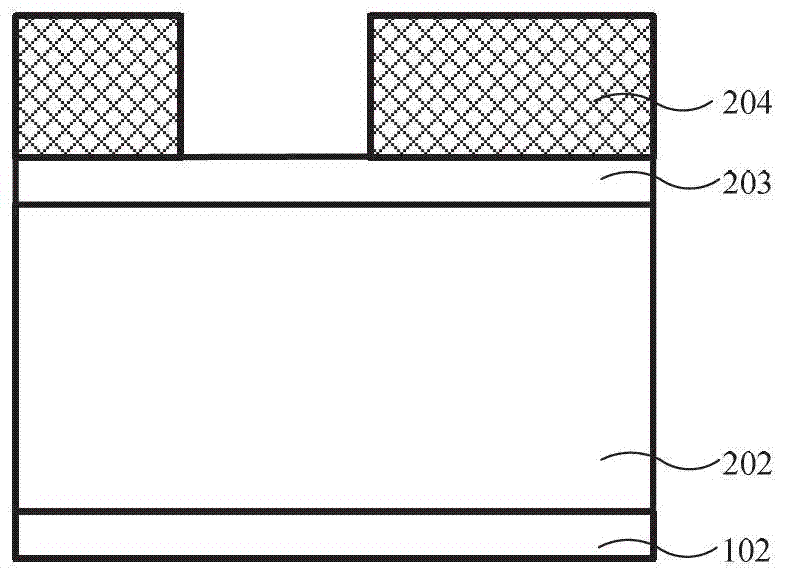

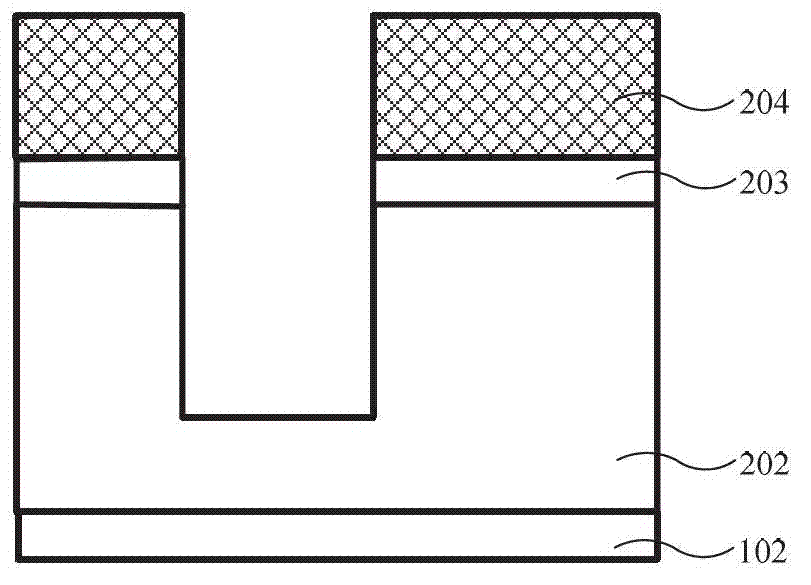

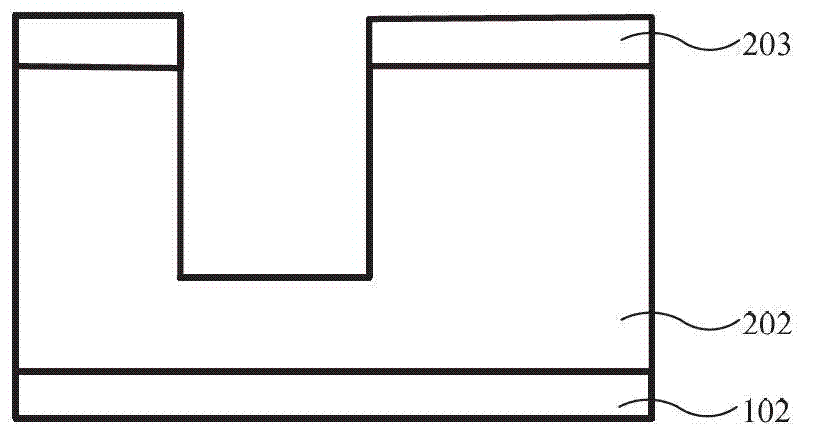

[0030] The above and other technical features and beneficial effects will be combined with the embodiments and the accompanying Figure 8-15 The method for forming the copper damascene structure of the present invention will be described in detail.

[0031] now attached Figure 8-15 , the method for forming the copper damascene structure of the present invention will be described in detail step by step through a specific embodiment.

[0032] Figure 8 It is a schematic flow chart of a preferred embodiment of the method for forming the copper damasc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com