Low-permeability, low-power consumption Fe-Si-Al soft magnetic material and production method thereof

A technology of soft magnetic materials and low magnetic permeability, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of high price and cost of gas atomization process, difficult to meet customer needs, and unsuitable for mass production , to achieve the effects of reducing oxygen content, using simple equipment, and reducing crushing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 1% Cr in the process of manufacturing sendust powder (the weight content of Si in the sendust powder material is 9%-10%, the weight content of Al is 5%-6%, and the balance is Fe), and then pass The traditional gas atomization process is used to prepare the new No. 1 sendust powder.

[0031] Take 1000g of No. 1 sendust powder, roast the prepared sendust powder until the temperature reaches 100°C, add 2.5% phosphoric acid diluent for surface treatment, and continue roasting until dry; then soften the sendust Magnetic powder compression molding: the pressure is 20 tons / cm 2 ; and through heat treatment, hydrogen or nitrogen gas is passed into the heat treatment furnace, the temperature is controlled at 750±3°C, and the heat treatment time is 150 minutes; finally, epoxy resin paint is used to coat the surface of the powder core. Obtained 2 sendust products with specifications of Φ26.9 / Φ14.7×11.2 (that is, the outer diameter is 26.9mm, the inner diameter is 14.7mm, and ...

Embodiment 2

[0050] Add 1% Cr (as Example 1) in the process of manufacturing sendust powder, and then pass through a similar amorphous rapid cooling process, that is, in the powder making process, the strip is made by using the high-speed cooling method of the strip machine, and the cooling rate is 10 5 ℃ / second; and the ordinary crushing method to obtain the new No. 2 sendust powder.

[0051] Take 1000g of No. 2 sendust powder, press the sendust powder into a size of Φ26.9 / Φ14.7×11.2 according to the process steps of Example 1 (that is, the outer diameter is 26.9mm, the inner diameter is 14.7mm, and the height is 11.2mm) Specifications of 2 sendust products. Other conditions remain unchanged.

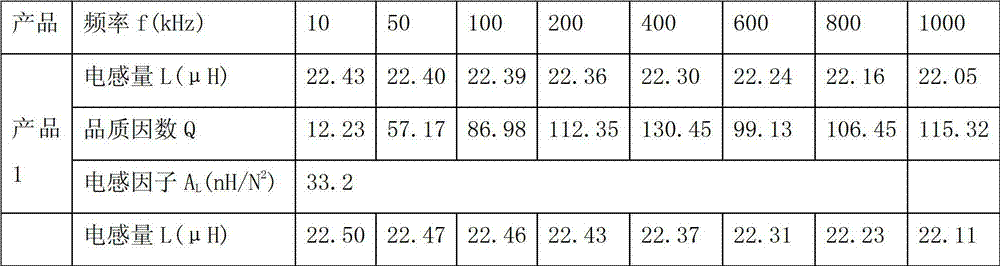

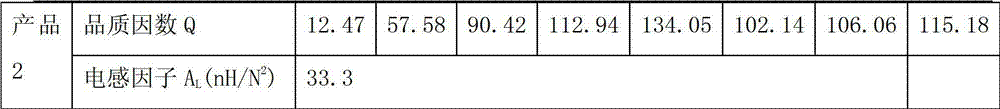

[0052] (1) f﹑L﹑Q test

[0053] The copper wire is Φ0.5mm, the number of coil turns is 26 turns, and its magnetic performance parameters are shown in Table 5

[0054] table 5

[0055]

[0056] (2) Power loss test

[0057] The copper wire is Φ0.8mm, the number of coil turns is 34 turns, and its...

Embodiment 3

[0069] Add 1% Cr (as Example 1) in the process of manufacturing sendust powder, and then pass through a similar amorphous rapid cooling process, that is, in the powder making process, the strip is made by using the high-speed cooling method of the strip machine, and the cooling rate is 10 4 ~10 6 °C / sec; and through mechanical crushing under the protection of the atmosphere, it is made into flat sendust powder.

[0070] Take 1000g of No. 3 sendust powder, press the sendust powder into a specification of Φ26.9 / Φ14.7×11.2 according to the process steps of Example 1 (that is, the outer diameter is 26.9mm, the inner diameter is 14.7mm, and the height is 11.2mm ) specifications of 2 sendust products.

[0071] Other conditions remain unchanged.

[0072] (1) f﹑L﹑Q test

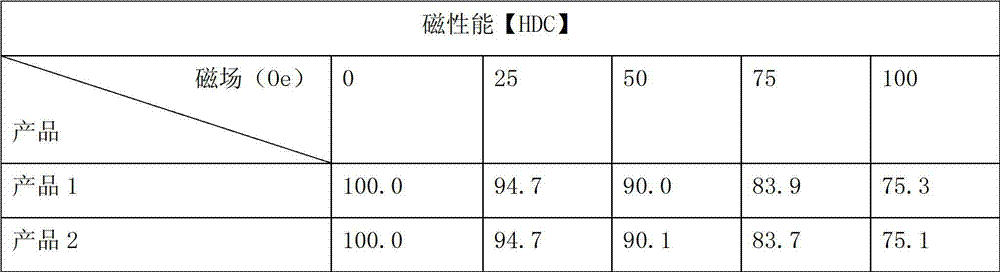

[0073] The copper wire is Φ0.5mm, the number of coil turns is 26 turns, and its magnetic performance parameters are shown in Table 9

[0074] Table 9

[0075]

[0076] (2) Power loss test

[0077] The copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com