High-temperature-resistant catalyst carrier and preparation method thereof

A catalyst carrier, high temperature resistant technology, applied in catalyst carriers, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of high cost of carriers and catalysts, accelerated loss of surface area, and inability to meet active components. , to achieve good application prospects, high surface area stability, and not easy to sinter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

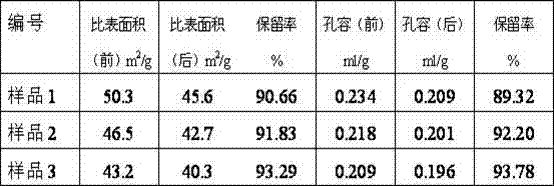

Examples

Embodiment 1

[0017] Take 153 grams of Al(OH) 3 , 129 g Zr(OH) 4 , 145 grams of Ti(OH) 4 Mix evenly, dry at 120°C, and then bake at 400°C for 5 hours to obtain primary carrier powder.

[0018] Take 835 grams of Al(NO 3 ) 3 , 551 g Zr(NO 3 ) 4 , 740 g Ti(NO 3 ) 4 Add it into 5L of water, add the primary carrier powder obtained above for beating under stirring to obtain slurry A, titrate A with 2mol / L sodium carbonate solution to pH=8.0, then filter and wash, dry at 120°C, and Calcined at 600°C for 5 hours to obtain secondary carrier powder;

[0019] Take 99.7 g La(NO 3 ) 3 , 99.4 g Ce(NO 3 ) 3 Dissolve in 5L of water, add the secondary carrier powder obtained above for beating under stirring to obtain slurry B, titrate B with 2mol / L sodium carbonate solution to pH = 9.0, then filter and wash, dry at 120°C, and Calcined at 1000°C for 5 hours to obtain high-temperature-resistant catalyst carrier powder, and molded to obtain high-temperature-resistant catalyst carrier, sample 1.

...

Embodiment 2

[0022] Take 153 grams of Al(OH) 3 , 129 g Zr(OH) 4 , 145 g Mg(OH) 2 100 grams of SiO2 were mixed evenly, dried at 120°C, and then calcined at 400°C for 5 hours to obtain a primary carrier powder;

[0023] Take 417 grams of Al(NO 3 ) 3 , 275 grams of Zr(NO 3 ) 4 , 555 g Mg(NO 3 ) 2 and 250 grams of 40% silica sol were added to 5L of water, and the primary carrier powder obtained above was added for beating under stirring to obtain slurry A, and A was titrated with 2 mol / L sodium hydroxide solution to pH = 10.0, and then filtered and washed , drying at 120°C, and roasting at 600°C for 6 hours to obtain a secondary carrier powder;

[0024] Take 99.7 g La(NO 3 ) 3 , 99.4 g Ce(NO 3 ) 3 and 96.5 g Sm(NO 3 ) 3 Dissolve in 5L of water, add the above-mentioned secondary carrier powder under stirring and beat to obtain slurry B, titrate B with 2mol / L sodium hydroxide solution to pH = 9.0, then filter, wash, and dry at 120°C. Calcined at 1100° C. for 5 hours to obtain a hi...

Embodiment 3

[0027] Take 290 grams of Mg(OH) 2 , 258 g Zr(OH) 4 , 290 grams of Ti(OH) 4 Mix evenly, dry at 120°C, and then bake at 450°C for 5 hours to obtain primary carrier powder;

[0028] Take 370 grams of Mg (NO 3 ) 2 , 278 grams of Zr(NO 3 ) 4 , 370 g Ti(NO 3 ) 4 Add it into 5L of water, and add the above-mentioned primary carrier powder under stirring to make a slurry to obtain slurry A. Use 2mol / L sodium carbonate solution to titrate A to pH = 10.0, then filter, wash, and dry at 120°C. Calcined at 700°C for 5 hours to obtain secondary carrier powder;

[0029] Take 40 grams of La(NO 3 ) 3 , 40 g Ce(NO 3 ) 3 , 38 g Sm(NO 3 ) 3 and 78 grams of Nd(NO 3 ) 3 Dissolve in 5L of water, add the above-mentioned secondary carrier powder for beating under stirring to obtain slurry B, titrate B with 4mol / L ammonia solution to pH=9.0, then filter and wash, dry at 120°C, and dry at 1200°C ℃ calcination for 5 hours to obtain high-temperature-resistant catalyst carrier powder, and s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com