Regeneration method of inactivated rhodium complex catalyst used for carbonyl reaction

A technology of carbonylation reaction and rhodium complexes, which is applied in the field of regeneration of deactivated or partially deactivated rhodium complex catalysts, to achieve the effects of improving catalyst activity, reducing dosage, and being easy to industrialize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

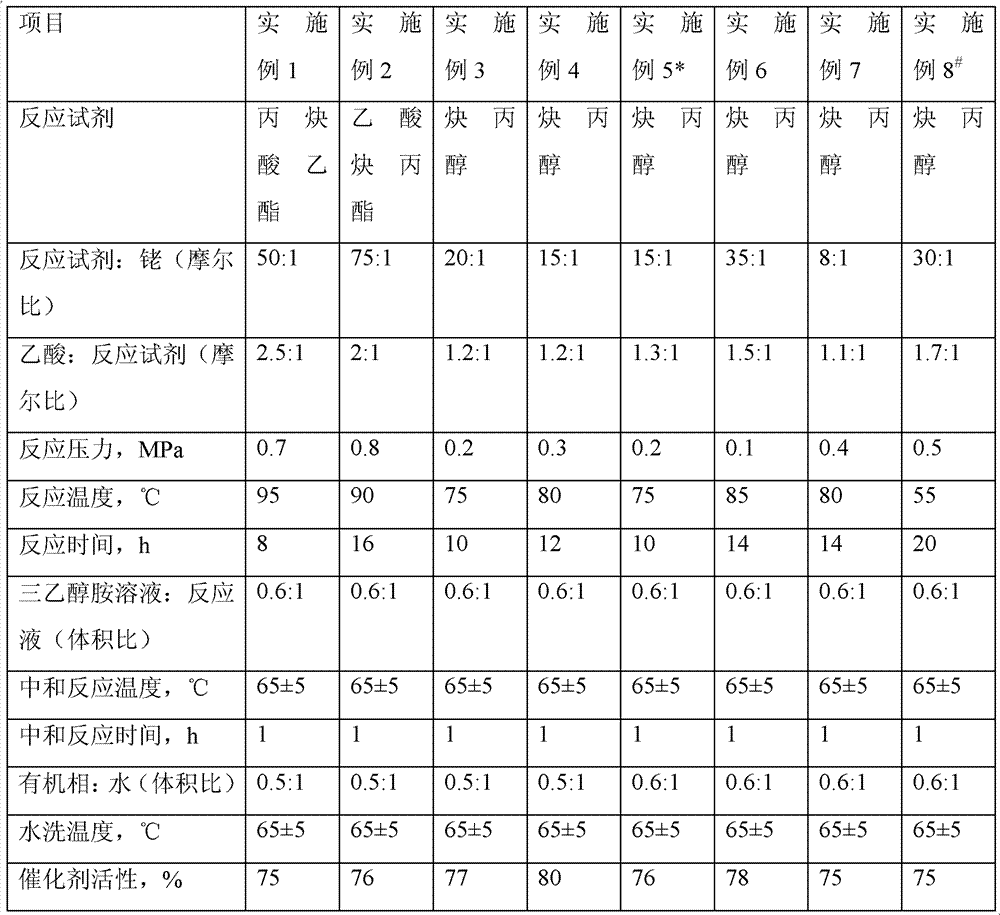

[0033] In the butyraldehyde reaction liquid produced by the industrial butanol device, the rhodium complex catalyst activity has been reduced from 100% to about 28% (compared with the fresh rhodium complex catalyst), and the rhodium content is about 1000mg / kg after removing part of the butyraldehyde , The content of triphenylphosphine is about 10%. Add 60 g of the reaction solution containing partially deactivated catalyst into a 100 ml reactor, purging the reactor with nitrogen, and then adding acetylenic alcohols or esters containing 3 to 6 carbon atoms in different proportions as shown in Table 1 React with carboxylic acid and perform regeneration reaction under certain pressure and temperature. After the reaction is finished, 10% triethanolamine aqueous solution is added into the reactor to neutralize unreacted carboxylic acid or halide to generate water-soluble salt.

[0034] After the neutralization reaction is finished, two distinct liquid phases are formed by static s...

Embodiment 5

[0036] Embodiment 5 is to pressurize to 0.2MPa with hydrogen, and other embodiments all use nitrogen.

Embodiment 8

[0037] Carboxylic acid used in embodiment 8 is n-butyric acid, and other embodiments all use acetic acid.

[0038] Table 1 Experimental conditions and catalyst activity evaluation table

[0039]

[0040] Description: The fresh rhodium complex catalyst activity is 100%, and the deactivated rhodium complex catalyst activity to be treated is 28%.

[0041] After testing, the chlorine content in the unregenerated reaction solution containing the partially deactivated rhodium complex catalyst was 29 mg / kg, and the chlorine content in the regenerated solution was 7 mg / kg. Therefore, compared with prior art, the processing method that the present invention adopts, has eliminated simultaneously because of exogenous halide poisoning and carboxylic acid inhibitor in the reaction liquid after regeneration, regeneration reaction reagent (containing the alkyne of 3~6 carbon atoms) Alcohol or ester) consumption is low, the reaction conditions are mild, the process flow is simple, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com