Ruthenium ammonia synthesis catalyst with high-specific-surface-area graphite as carrier and preparation of ruthenium ammonia synthesis catalyst

A high specific surface area, catalyst technology, applied in catalyst carrier, ammonia preparation/separation, chemical instruments and methods, etc., can solve the problems of low specific surface area and small pore volume of ordinary graphite, and achieve high catalyst activity and simple equipment structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

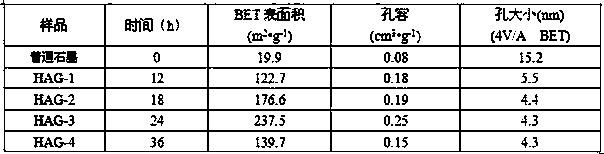

[0022] (1) Weigh graphite with a mass of 4.00 g and a magnetic steel needle with a mass of 20.00 g (the size of the magnetic steel needle is 1mm) and place them in a closed 400mL glass container filled with air; use a water bath to control the temperature at 40°C , run continuously at 1800 r / min for different t times, then add 20mL of deionized water and continue to rotate for 2h, then sedimentation, filtration, separation and drying to obtain high specific surface graphite solid powder; high specific surface graphite physical texture prepared by different magnetic grinding time The structure is shown in Table 1 below;

[0023] Table 1 Physical texture of high specific surface graphite obtained under different magnetic grinding times

[0024]

[0025] (2) Preparation of potassium ruthenate: put ruthenium powder and potassium hydroxide in a nickel crucible and mix evenly, and treat in a muffle furnace at 400°C for 4 hours to obtain potassium ruthenate;

[0026] (3) Catalyst...

Embodiment 2

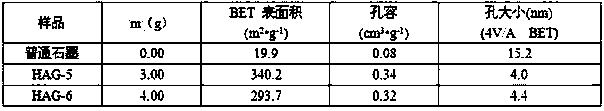

[0029] Change the graphite mass m and replace the magnetic grinding container with a 200mL glass container. The magnetic grinding time is 12h, and other conditions are the same. The physical texture of graphite with large specific surface area prepared by the same steps is shown in Table 2;

[0030] Table 2 Physical texture of large specific surface graphite prepared with different ball-to-material ratios

[0031]

[0032] (2) Preparation of potassium ruthenate: put ruthenium powder and potassium hydroxide in a nickel crucible and mix them evenly, and treat them in a muffle furnace at 650°C for 1 hour to obtain potassium ruthenate. The content of ruthenium is 4% of the mass of the carrier;

[0033] (3) Catalyst preparation: Immerse the high specific surface graphite carrier HAG-5 obtained in step (1) in the solution of potassium ruthenate obtained in step (2) by equal-volume impregnation method, and control the temperature at 60°C. The impregnation time is 3 minutes; the im...

Embodiment 3

[0036] Take the ordinary graphite in Example 2 as the carrier, the content of ruthenium is 4% of the carrier mass, the amount of additive Ba is 2% of the carrier mass, the hydrogen-nitrogen ratio in the mixed gas is 3:1, and the space velocity is 10000 h -1 , the tableting pressure is 10 MPa, and the reaction temperature is 400 ℃, the optimum activity of ruthenium-based ammonia synthesis catalyst is 2.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com