Catalyst for concurrently removing CO, CH, NOx and PM, and preparation method thereof

A technology of catalysts and composite oxides, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxides/metal hydroxide catalysts, etc., can solve the problem of ineffective removal of HC and CO in automobiles, which needs to be further explored , general catalytic activity, etc., to achieve the effect of facilitating large-scale production, breaking through technical bottlenecks, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

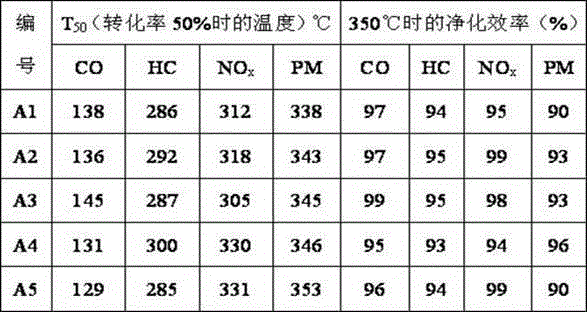

Examples

Embodiment 1

[0026] This example illustrates the simultaneous removal of CO, CH, and NO provided by the present invention x , PM catalyst preparation.

[0027] (1) Preparation of self-made carrier:

[0028] Take 30g of silica, 40g of alumina and 30g of magnesia and mix them evenly, extrude them into a muffle furnace, roast at 1300°C for 6h, then boil with oxalic acid with a mass concentration of 5% for 2h, then pass through 80°C, Dry for 2 hours, and bake at 400°C for 6 hours to obtain a self-made honeycomb ceramic carrier;

[0029] (2) Preparation of active component impregnation solution

[0030] Impregnation solution 1: first prepare an aqueous solution of lanthanum nitrate, cerium nitrate, copper nitrate, and zirconium nitrate, add an appropriate amount of complexing agent ammonium citrate solution, and place it in a constant temperature water bath at 90°C until it is in the form of a sol; prepare the obtained Ce 0.1 Zr 0.9 LaCuO xIn the active formula, the molar ratio of Ce and Z...

Embodiment 2

[0035] This example illustrates a simultaneous removal of CO, CH, and NO provided by the present invention x , PM catalyst preparation.

[0036] (1) Preparation of self-made carrier:

[0037] Take 40g of silica, 30g of alumina and 30g of magnesia, mix them evenly, extrude them into a muffle furnace, roast them at 1400°C for 6 hours, boil them in nitric acid with a mass concentration of 10% for 2 hours, and heat them at 80°C. Dry for 2 hours, and bake at 400°C for 6 hours to obtain a self-made honeycomb ceramic carrier;

[0038] (2) Preparation of active component impregnation solution

[0039] Impregnation solution 1: first prepare an aqueous solution of lanthanum acetate, cerium acetate, cobalt acetate, and zirconium acetate, and add an appropriate amount of complexing agent ammonium citrate solution, and place it in a constant temperature water bath at 90°C until it is in the form of a sol; prepare the obtained La 0.3 Zr 0.7 CaCO x The molar ratio of La and Zr in the ac...

Embodiment 3

[0044] This example illustrates a simultaneous removal of CO, CH, and NO provided by the present invention x , PM catalyst preparation.

[0045] (1) Preparation of self-made carrier:

[0046] Take 55g of silica, 20g of alumina and 25g of magnesia, mix them evenly, extrude them into a muffle furnace, roast them at 1400°C for 4 hours, then boil them with 20% acetic acid for 3 hours, then heat them at 120°C for 1 hour Drying and firing at 600°C for 4 hours to obtain a self-made honeycomb ceramic carrier;

[0047] (2) Preparation of active component impregnation solution

[0048] Impregnation solution 1: first prepare the aqueous solution of neodymium oxalate, praseodymium oxalate, manganese oxalate, and zirconium oxalate, add an appropriate amount of complexing agent urea solution, and place it in a constant temperature water bath at 90°C until it is in the form of a sol; prepare the obtained Nd 0.5 Zr 0.5 PrMnO x The molar ratio of Nd and Zr in the active formula is 0.5:0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com