Method for preparing positive material of high-power lithium ion battery

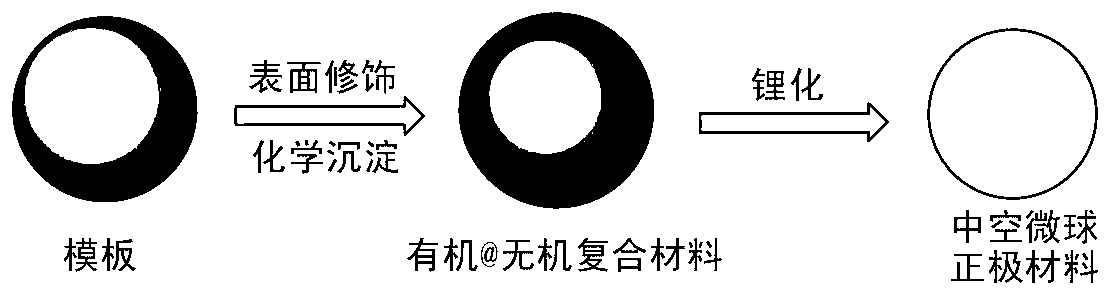

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low electrical conductivity, achieve uniform particle size distribution, shorten intercalation/deintercalation, and enhance storage/release capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

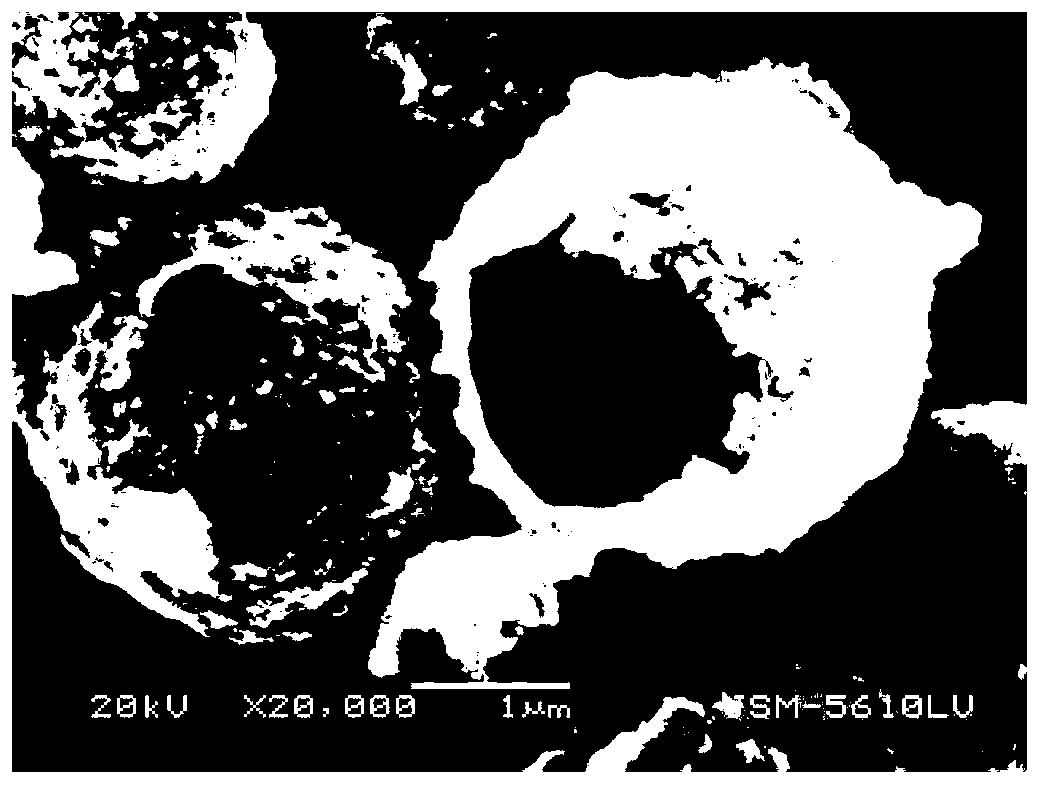

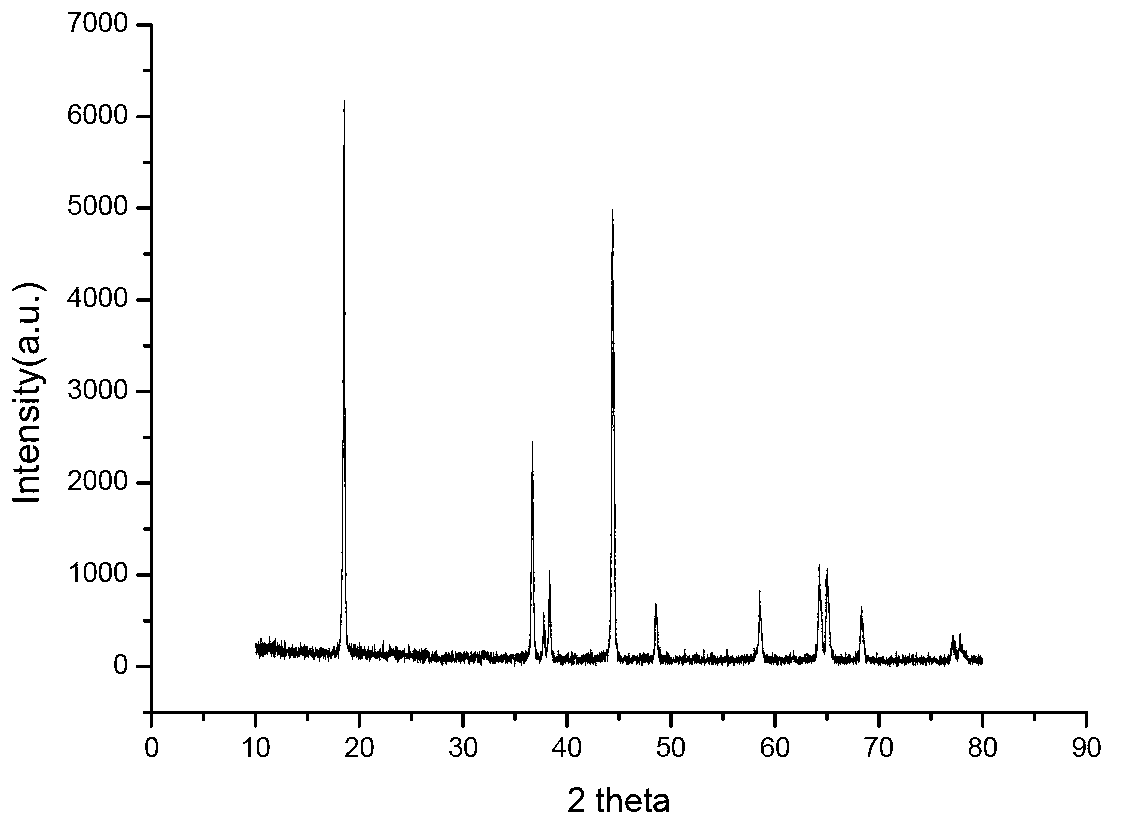

[0023] Take 2 mL of polystyrene balls (~2 μm) in a 50 mL beaker, add 5 mL of 95% ethanol and 25 mL of deionized water dropwise, and disperse them by ultrasonication for 10 min. , CoSO4, MnSO4 (molar ratio Ni:Co:Mn=1:1:1) solution B and CO(NH 2 ) 2 Solution A was added to the beaker one by one, CO(NH 2 ) 2 The molar ratio to the metal salt is 6:1, and the stirring speed is 300rph. After reacting for 24 hours, it was heated and filtered, and the filter cake was vacuum-dried at 80°C. with LiNO 3 After mixing according to the metering ratio, put it in a muffle furnace, raise the temperature to 450°C at a heating rate of 5°C / min, and keep it at this temperature for 5h. Then the temperature was raised to 850°C at a heating rate of 10°C / min, kept at this temperature for 24h, and then directly quenched in air to room temperature. Obtain the positive electrode ternary material LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 .

Embodiment 2

[0025] Take 1mL polypropylene ball (100nm) and 50mL beaker, add dropwise 5mL of 95% ethanol, 15mL of deionized water, and ultrasonic for 10min to disperse it, take it out, put it in a constant temperature water bath at 80°C, and dissolve the dissolved NiCl 2 、CoCl 2 , MnCl 2 (molar ratio Ni:Co:Mn=8:1:1) solution B and (NH 4 ) 2 CO 3 Solution A was added to the beaker in turn, (NH 4 ) 2 CO 3 The molar ratio to the metal salt is 4:1, and the stirring speed is 300rph. After reacting for 24 hours, it was heated and filtered, and the filter cake was vacuum-dried at 80°C. After mixing with LiOH according to the metering ratio, put it in a muffle furnace, raise the temperature to 480°C at a heating rate of 2°C / min, and keep it at this temperature for 4h. Then the temperature was raised to 800°C at a heating rate of 5°C / min, kept at this temperature for 28h, and then directly quenched in air to room temperature. Obtain the positive electrode ternary material LiNi 0.8 co 0.1...

Embodiment 3

[0027]Take 1mL polymethyl methacrylate balls (30nm) and 50mL beaker, add dropwise 5mL of 95% ethanol, 15mL of deionized water, and ultrasonic for 10min to disperse it, take it out, put it in a constant temperature water bath at 80°C, and dissolve the Ni(NO 3 ) 2 , Co(NO 3 ) 2 , Mn(NO 3 ) 2 (molar ratio Ni:Co:Mn=4:2:2) solution B and NH 4 HCO 3 Solution A was added to the beaker in turn, NH 4 HCO 3 The molar ratio to the metal salt is 5:1, and the stirring speed is 300rph. After reacting for 24 hours, it was heated and filtered, and the filter cake was vacuum-dried at 80°C. After mixing with LiOH according to the metering ratio, put it in a muffle furnace, raise the temperature to 480°C at a heating rate of 2°C / min, and keep it at this temperature for 6h. Then the temperature was raised to 860°C at a heating rate of 6°C / min, kept at this temperature for 12h, and then directly quenched in air to room temperature. Obtain the positive electrode ternary material LiNi 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com