Method of preparing n-type counterfeit ternary erbium-doped thermoelectric material by utilizing mechanical alloying cold pressing sintering method

A technology of mechanical alloying and thermoelectric materials, applied in the field of preparing thermoelectric materials, can solve the problems of poor mechanical properties, easy splitting, high device production cost, reduce porosity, reduce splitting phenomenon, and low requirements for equipment and process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

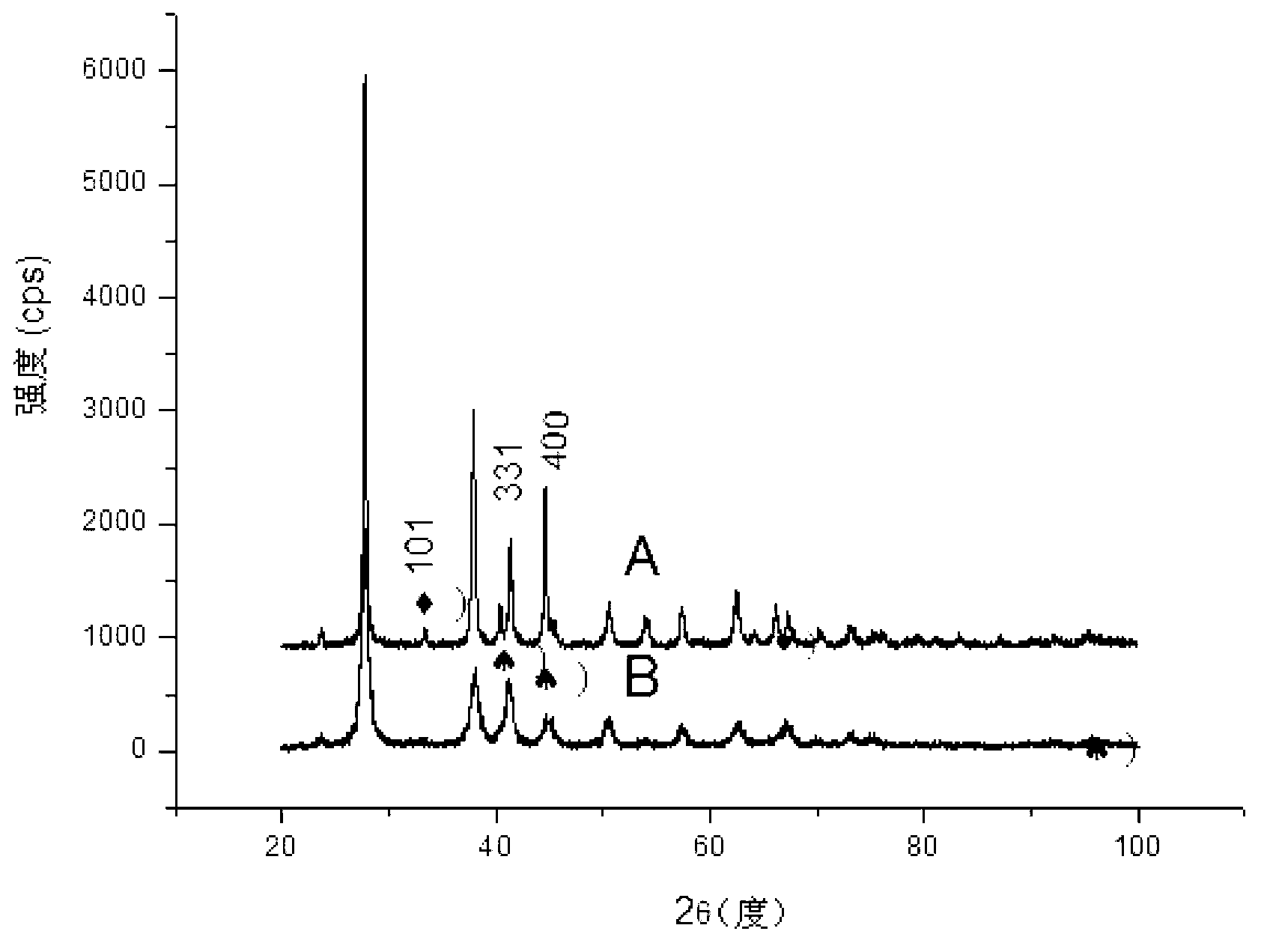

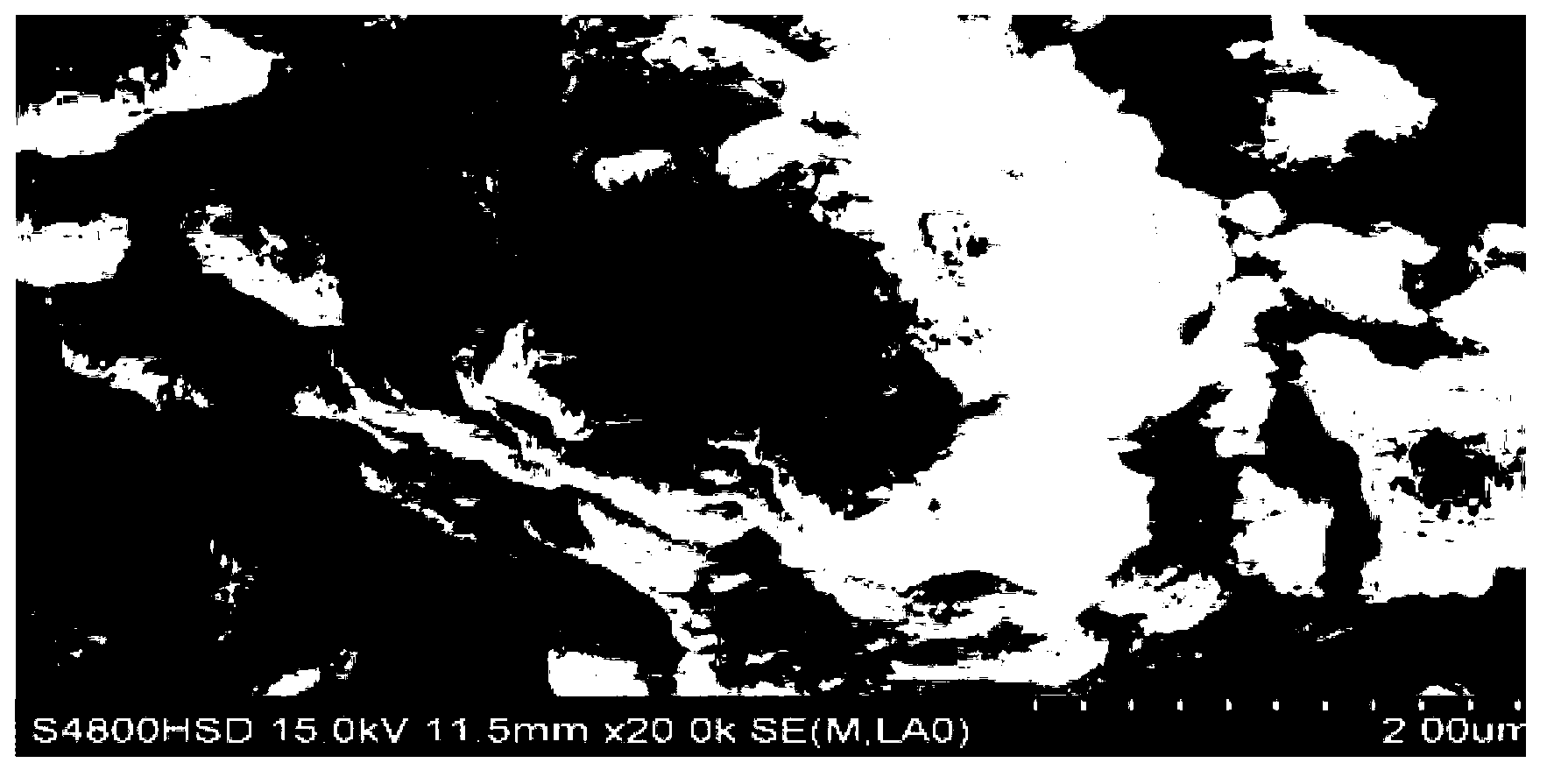

[0021] Specific implementation mode one: In this implementation mode, the n-type pseudo-ternary erbium-doped thermoelectric material ((Bi 2 Te 3 ) 0.90 (Sb 2 Te 3 ) 0.05 (Sb 2 Se 3 ) 0.05 ) method is as follows:

[0022] 1. Weigh elemental Bi, elemental Sb, elemental Te and elemental Se according to the ratio of Bi element, Sb element, Te element and Se element molar ratio of 180:2:285:15, and elemental Bi, elemental Sb, elemental Te and Elemental Se is mixed, and then rare earth element Er is added to obtain a mixture. The amount of rare earth element Er added is 0.1% to 2.0% of the total mass of elemental Bi, elemental Sb, elemental Te, elemental Se and rare earth element Er, and the mixture is crushed to a particle size 1mm to 10mm, using petroleum ether as the ball milling medium, under the conditions of a rotating speed of 410r / min and a ball-to-material ratio of 10:1, mechanical ball milling for 100h to obtain alloy powder;

[0023] 2. Press the alloy powder int...

specific Embodiment approach 2

[0026] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the purity of the elemental Bi described in step 1 is 99.99%. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the purity of the elemental Sb in step 1 is 99.99%. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com