High-voltage preparation method of Er-doped bismuth telluride-based pseudo ternary thermoelectric material

A bismuth telluride-based pseudo-thermoelectric material technology, which is applied in the manufacture/processing of thermoelectric devices, thermoelectric device node lead-out materials, etc., can solve the problems of ZT value reduction and achieve lattice thermal conductivity reduction, power transmission The effect of improved transport performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] High pressure preparation method using ER doped tantaltinate three-membered thermoelectric material

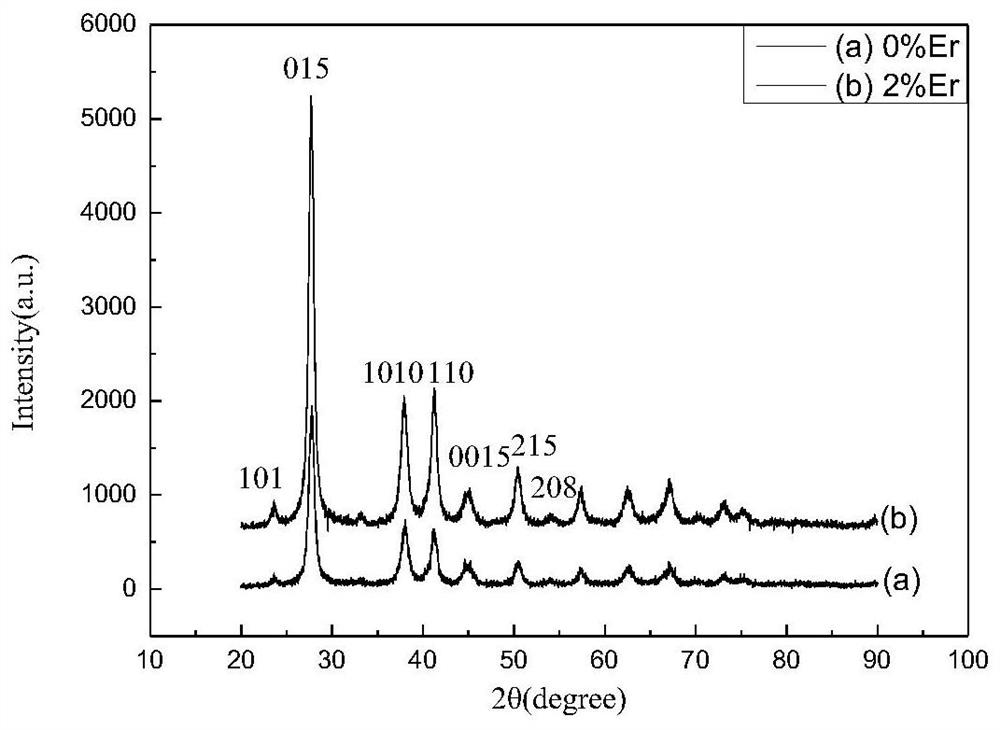

[0034] 1. According to BI powder (99.99%), Sb powder (99.99%), SE powder (99.99%) and TE powder (99.99%) according to the chemical measurement ratio (molar ratio of 180: 2: 285: 15), will A well raw material is encapsulated into a vacuum glass tube, and the vacuum smelting is carried out at a temperature of 800 ° C, and the powder is synthesized (Bi 2 TE 3 ) 0.90 (SB 2 TE 3 ) 0.05 (SB 2 SE 3 ) 0.05 Orientation crystals.

[0035] 2, will be (BI) 2 TE 3 ) 0.90 (SB 2 TE 3 ) 0.05 (SB 2 SE 3 ) 0.05 The orientation crystal is broken into a powder, and the rare earth element Er is added, and the mixture is obtained, wherein the amount of the rare earth element ER is 0.1% of the total mass. The mixture was pulverized to about 1 mm, and the petroleum ether is a ball milling medium, under the condition of 410 r / min, the spherium is 10: 1, the mechanical ball milling 50 h, the rare ...

Embodiment 2

[0040] High pressure preparation method using ER doped tantaltinate three-membered thermoelectric material

[0041] 1. According to BI powder (99.99%), Sb powder (99.99%), SE powder (99.99%) and TE powder (99.99%) according to the chemical measurement ratio (molar ratio of 180: 2: 285: 15), will A well raw material is encapsulated into a vacuum glass tube, and the vacuum smelting is carried out at a temperature of 800 ° C, and the powder is synthesized (Bi 2 TE 3 ) 0.90 (SB 2 TE 3 ) 0.05 (SB 2 SE 3 ) 0.05 Orientation crystals.

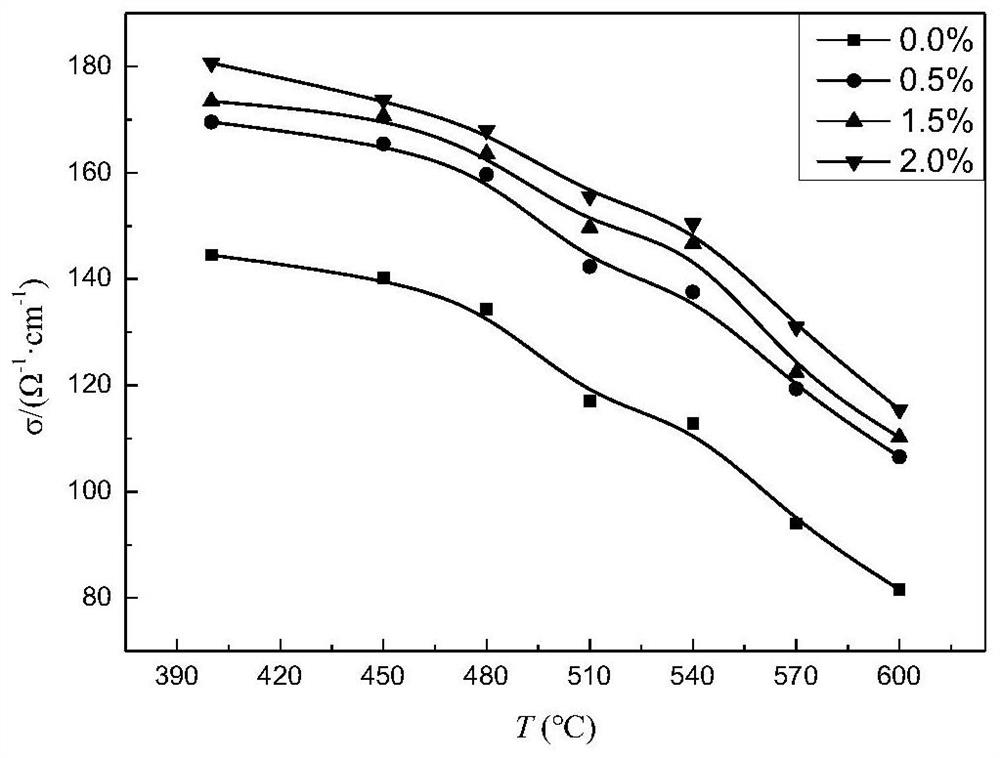

[0042] 2, will be (BI) 2 TE 3 ) 0.90 (SB 2 TE 3 ) 0.05 (SB 2 SE 3 ) 0.05 The orientation crystal is broken into a powder, and the rare earth element Er is added, and the mixture is obtained, wherein the amount of rare earth element Er is 0.5% of the total mass. The mixture was pulverized to about 1 mm, and the petroleum ether is a ball milling medium, under the condition of 410 r / min, the spherium is 10: 1, the mechanical ball milling 50 h, the rare eart...

Embodiment 3

[0047] High pressure preparation method using ER doped tantaltinate three-membered thermoelectric material

[0048] 1. According to BI powder (99.99%), Sb powder (99.99%), SE powder (99.99%) and TE powder (99.99%) according to the chemical measurement ratio (molar ratio of 180: 2: 285: 15), will A well raw material is encapsulated into a vacuum glass tube, and the vacuum smelting is carried out at a temperature of 800 ° C, and the powder is synthesized (Bi 2 TE 3 ) 0.90 (SB 2 TE 3 ) 0.05 (SB 2 SE 3 ) 0.05 Orientation crystals.

[0049] 2, will be (BI) 2 TE 3 ) 0.90 (SB 2 TE 3 ) 0.05 (SB 2 SE 3 ) 0.05 The orientation crystal is broken into a powder, and the rare earth element Er is added, and the mixture is obtained, wherein the amount of the rare earth element ER is 1.0% of the total mass. The mixture was pulverized to about 1 mm, and the petroleum ether is a ball milling medium, under the condition of 410 r / min, the spherium is 10: 1, the mechanical ball milling 50 h, the rare ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com