Integrated-type LED (light-emitting diode) light source heat radiating device and preparation method thereof

A technology for an LED light source and a heat sink, which is applied in the field of an integrated LED light source heat sink and its preparation, can solve the problems that the LED cannot reach a large power value, it is difficult to meet the LED standard and device standard, and the brightness and photoelectric conversion rate are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

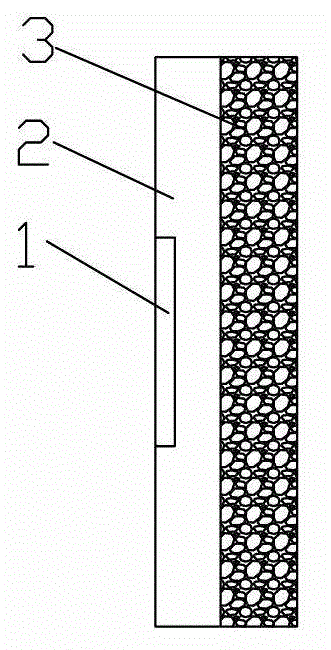

[0086] When the LED chip is 30W, the main structure of the integrated LED light source cooling device adopts a double-layer overlapping structure;

[0087] Material preparation:

[0088] The first layer (i.e. the base):

[0089] Material A: silicon carbide powder (quality 95%, the quality here is the mass content of silicon carbide); fineness 240 mesh;

[0090] Material B: silicon carbide powder fineness 90 mesh;

[0091] Mass ratio: material A: material B=7:3;

[0092] Silica sol [Quality is above 12%. That is, containing more than 12% silicon] is 15% of the total mass of material A and material B.

[0093] The second layer (ie heat sink):

[0094] (1) Material C: silicon carbide powder fineness 80 mesh

[0095] (2) Material D: silicon carbide powder fineness 100 mesh

[0096] Mass ratio: material C: material D=7:3;

[0097] (3) Epoxy resin (mass is 10% of the total mass of material C and material D)

[0098] (4) Pore-forming agent ethyl naphthalene (mass is 3% of th...

example 2

[0104] When the LED chip is 50W, the main structure of the integrated LED light source cooling device adopts a double-layer overlapping structure;

[0105] Material preparation:

[0106] First layer (pedestal):

[0107] (1) Material A: silicon carbide powder (quality 95%) with a fineness of 60 mesh, or use ceramic fiber ceramic particles

[0108] (2) Material B: silicon carbide powder (quality 95%) fineness 100 mesh

[0109] Mass ratio: Material A: Material B=6:4

[0110] (3) Silica sol [the quality is above 12%. That is, containing more than 12% silicon] is 15% of the total mass of material A and material B.

[0111] The second layer (heat sink):

[0112] (1) Material C: silicon carbide powder fineness 30 mesh

[0113] (2) Material D: silicon carbide powder fineness 80 mesh

[0114] Mass ratio: material C: material D=6:4;

[0115] (3) Epoxy resin (mass is 20% of the total mass of material C and material D)

[0116] (4) Pore-forming agent ethyl naphthalene (mass is 1...

example 4

[0122] Step 1: Prepare the base;

[0123] Prepare material A with a fineness of 240 mesh, material B with a fineness of 90 mesh, and silica sol; material A is at least one of silicon carbide powder, ceramic fiber and ceramic particles; material B is silicon carbide powder;

[0124] The mass ratio of material A and material B is 7:3;

[0125] The quality of silica sol is 15% of the total mass of material A and material B;

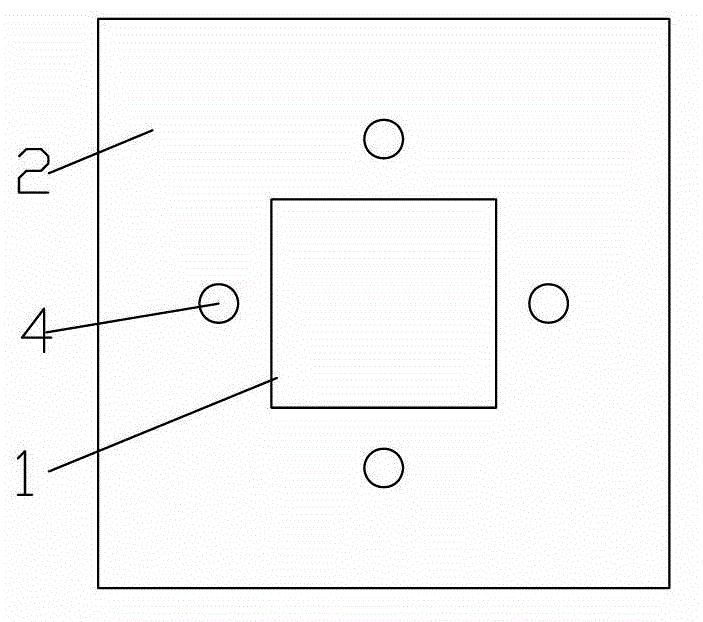

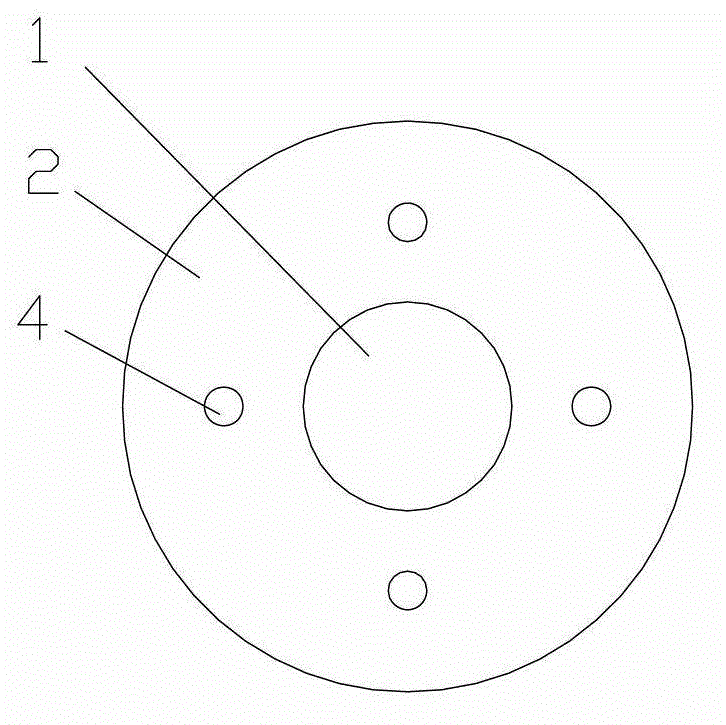

[0126] Coat the release agent on the first preform mold, put the printed circuit board (0.5-1.5mm thick copper foil thickness) into the first preform mold; use silica sol to mix material A and material B evenly as Die-casting raw materials for die-casting, demoulding after die-casting; pressure range 150-300 N; drying after demoulding, that is, the preparation of the base is completed;

[0127] Step 2: Grinding and packaging:

[0128]There is a packaging groove at the front end of the base (you can also not set the packaging groove, just solder the LED ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com