led car headlights

A technology for automobile headlights and lamp sockets, which is applied in the directions of damage prevention measures for lighting devices, cooling/heating devices for lighting devices, lighting and heating equipment, etc. Large temperature difference in structure, shadows and other problems, to achieve good heat dissipation, improve luminous efficiency, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

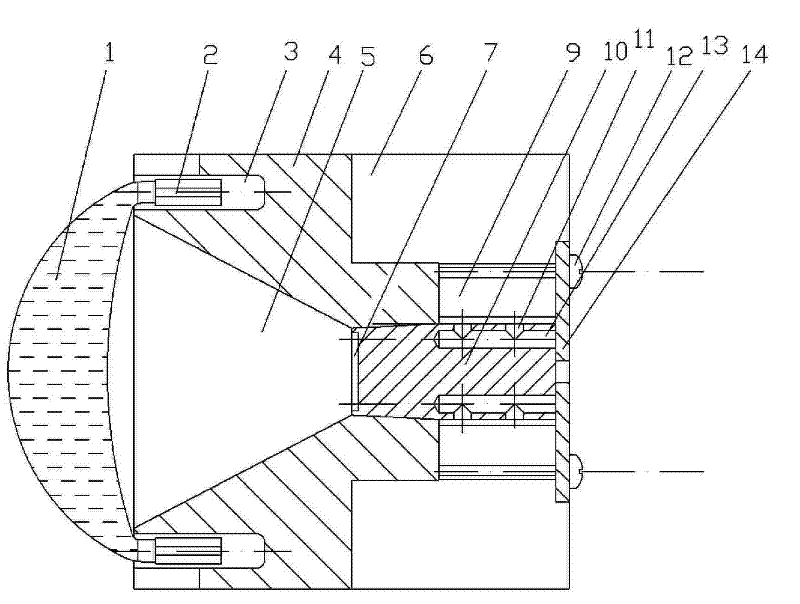

[0037] Such as Figure 1~4 Shown, a kind of LED automobile headlight is characterized in that, comprises lamp holder 4, cooling rod 10, lens 1 and LED chip 7;

[0038] The front end of the lamp holder 4 has a conical cavity 5 used as a lamp bowl, the large end face of the conical cavity 5 is on the front face of the lamp holder 4; a through hole, the through hole communicates with the conical cavity;

[0039] The front end surface of the lamp holder 4 is provided with an annular groove 3, the lens 1 covers the large end of the conical cavity 5, and the edge portion 2 of the lens is inserted into the annular groove 3;

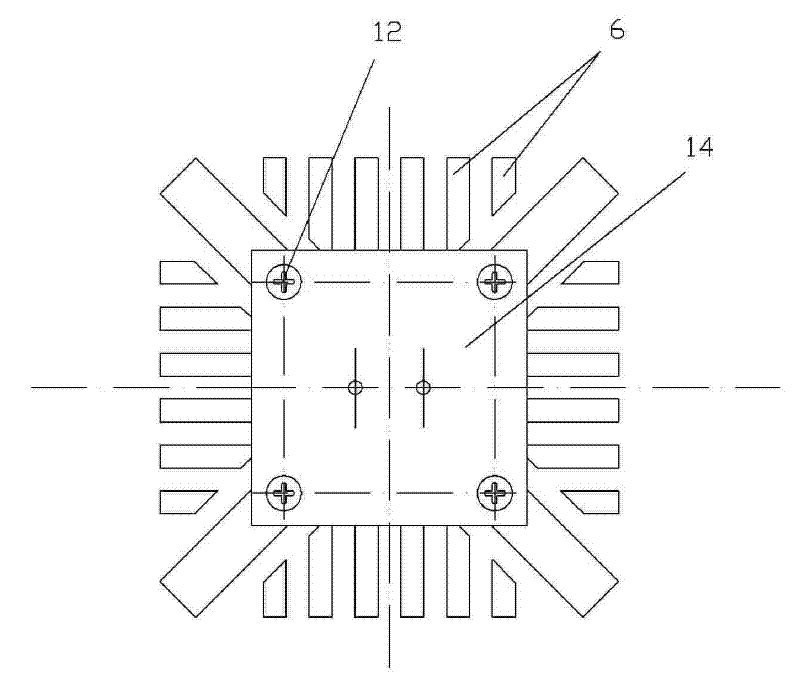

[0040] The front end of the heat dissipation rod 10 is inserted into the through hole; the LED chip 7 is directly arranged on the front end surface of the heat dissipation rod 8; The overall shape of the automobile headlight is a cuboid whose front end is a square.

[0041] The rear end of the lamp holder 4 is provided with a plurality of cooling fins 6, and ...

Embodiment 2

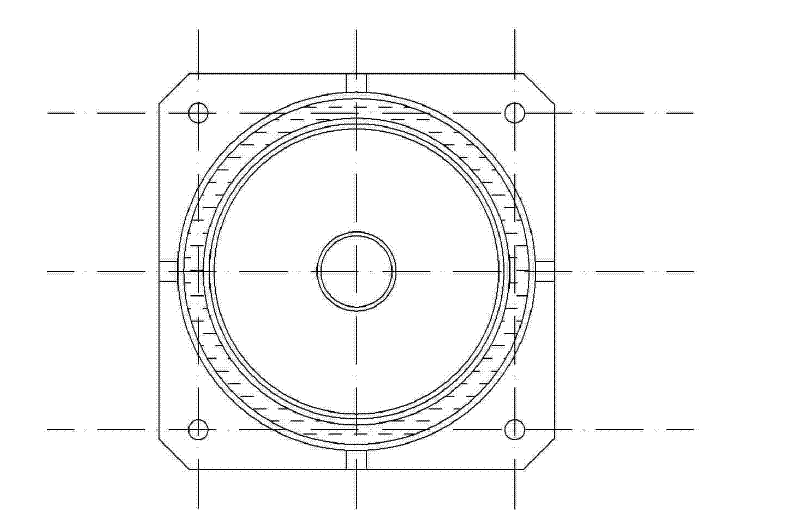

[0048] Such as Figure 5-6 As shown, the overall shape of the LED automobile headlight is cylindrical. All the other structures are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com