Nickel-based nickel titanium hydrotalcite film material, preparation method and application thereof

A nickel-titanium hydrotalcite and thin film technology, applied in metal material coating process, coating, liquid chemical plating and other directions, can solve problems such as limited application, and achieve the effect of large contact area, tight bonding, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

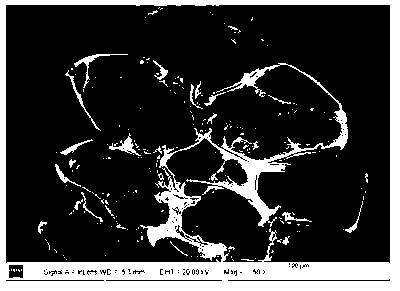

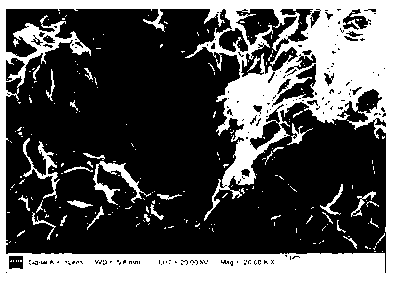

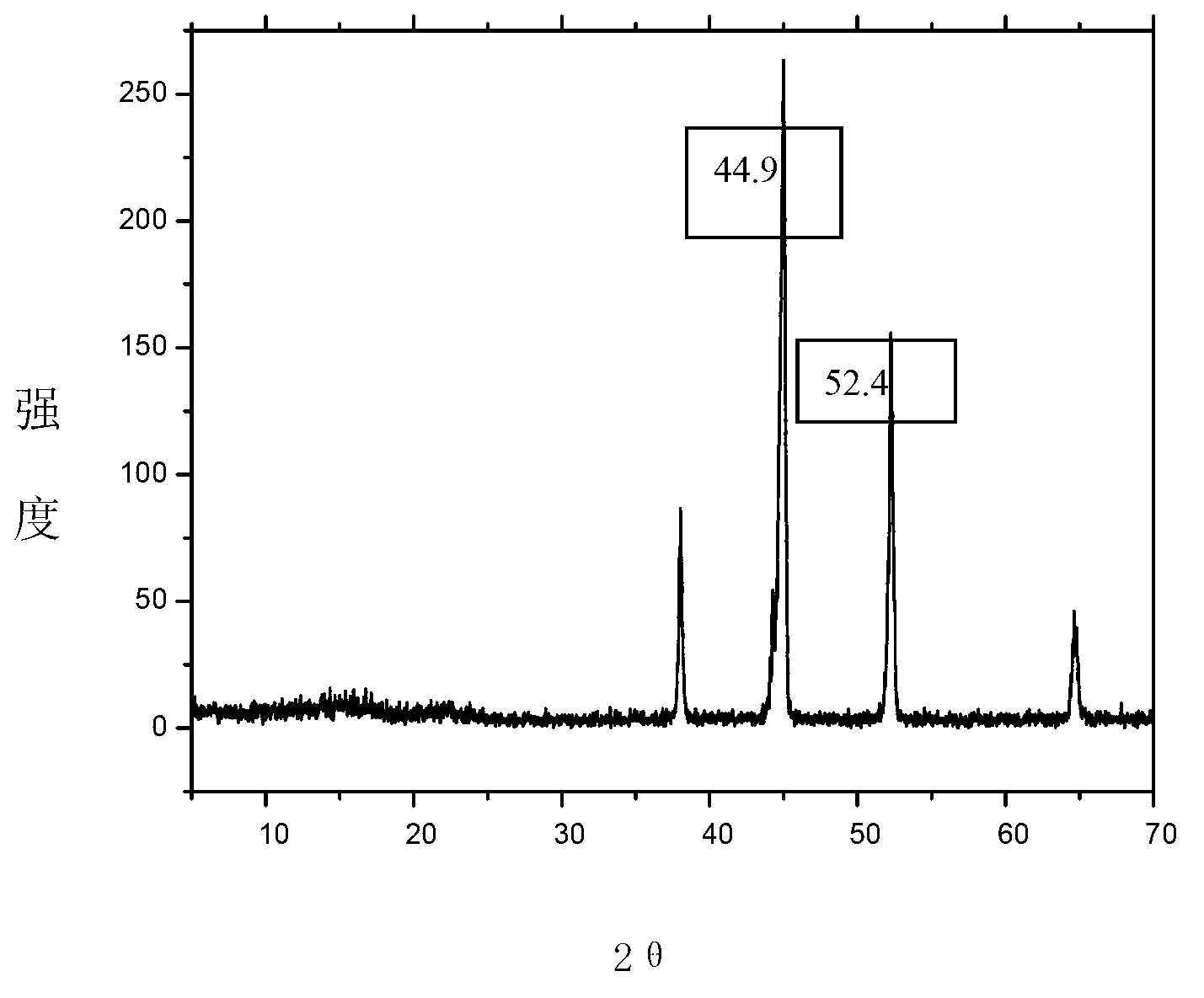

[0036] A. Use nickel foam with a purity greater than 90% as the base material, cut into pieces of 10*15cm in size, wash with 30% concentrated hydrochloric acid for 50s, then ultrasonically clean with deionized water for 3 times, clean with absolute ethanol once, put in 60 Dry in an oven at °C for later use.

[0037] B. 26.4g Ti(SO 4 ) 2 and 58.15gNi(NO 3 ) 2 Prepared into 1000ml solution a, and then 17.5g Na with deionized water 2 CO 3 Prepare 200ml solution b with 18.65g NaOH. Put the nickel foam treated in step A into solution a, then add solution b dropwise into solution a under strong stirring until the pH of the solution reaches 9.5, transfer them to a polytetrafluoroethylene reactor and put them in an oven React at 90°C for 6h. After the reaction was finished, the nickel foam was taken out, excess sediment on the surface was washed off with deionized water, and dried at 60° C. for 12 hours.

[0038] C. Prepare the same 1000ml solution c as solution a in step B...

Embodiment 2

[0040] A. Use nickel foam with a purity greater than 90% as the base material, cut into pieces of 10*15cm in size, wash with 30% concentrated hydrochloric acid for 50 seconds, then ultrasonically clean with deionized water for 3 times, clean with absolute ethanol once, put in 60 ℃ oven dry.

[0041] B. 39.6g Ti(SO 4 ) 2 and 87.24gNi(NO 3 ) 2 Prepare 800ml solution a, then prepare 28gNOH and 23.3gNa with deionized water 2 CO 3 225ml mixed solution b. Put the nickel foam treated in step A into solution a, then add solution b dropwise into solution a under strong stirring until the pH of the solution reaches 9, then transfer them together to a 1000ml beaker, and seal the beaker with plastic wrap mouth. Stir vigorously in a water bath at 60°C and react for 5 hours. After the reaction, take out the nickel foam and clean it with deionized water, put it in an oven, and dry it at 60°C for 12 hours.

[0042] C. 26.4g Ti(SO 4 ) 2 and 58.15g Ni(NO 3 ) 2 Prepare 1000ml solu...

Embodiment 3

[0044] A. Use nickel foam with a purity greater than 90% as the base material, cut into pieces of 10*15cm in size, wash with 30% concentrated hydrochloric acid for 50 seconds, then ultrasonically clean with deionized water for 3 times, clean with absolute ethanol once, put in 60 ℃ oven dry.

[0045] B. 19.8g Ti(SO 4 ) 2 and 43.6g Ni(NO 3 ) 2 Prepare 750ml of solution a, use deionized water to dissolve 14gNOH and 11.85gNa 2 CO 3 Prepare 250ml of solution b, put the nickel foam treated in step A into solution a, then add solution b dropwise into solution a under strong stirring until the pH of the solution reaches 8.5, and then add it to the tetrafluoroethylene removal reaction In the kettle, react at 80°C for 10h. After the reaction, the nickel foam was cleaned, put into an oven, and dried at 60° C. for 12 hours for later use.

[0046] C. 19.8g Ti(SO 4 ) 2 and 43.6g Ni(NO 3 ) 2 Prepare 750ml of solution c, then use deionized water to mix 60ml of ammonia water with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com