Environment-friendly neoprene sealant and preparation method thereof

The technology of sealant and chloroprene is applied in the field of environmentally friendly chloroprene sealant and its preparation, which can solve problems such as construction environment hazards, and achieve the effects of good constructability, good sealing performance and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

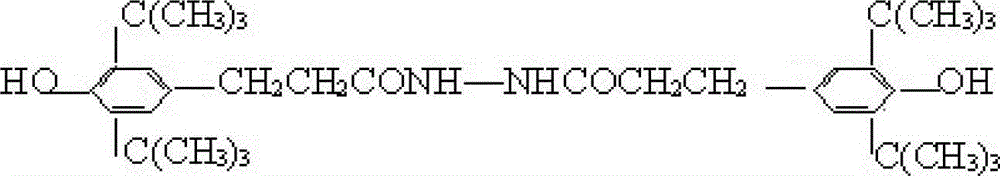

Embodiment 1

[0027] Environmentally friendly neoprene sealant, which includes the following components: neoprene rubber, fillers (including talcum powder, light calcium, magnesium oxide and titanium dioxide), ester solvents (including methyl acetate, ethyl acetate and butyl acetate) , Solvent oil (6# solvent oil and 120# solvent oil), plant extract essential oil (turpentine oil), softener (including stearic acid and transformer oil), antioxidant 300.

[0028] Wherein neoprene rubber, filler, ester solvent, mineral spirits, plant extract essential oil, softening agent, antioxidant 300% by weight are as follows: 14%, 28.9%, 19%, 20%, 10%, 8% %, 0.1%.

[0029] The weight ratio of talcum powder, light calcium, titanium dioxide and magnesium oxide in the filler is 20:5:5:1 in sequence.

[0030] The weight ratio of methyl acetate, ethyl acetate and butyl acetate in the ester solvent is 1:4:5 in sequence.

[0031] The weight ratio of 6# solvent oil and 120# solvent oil in solvent oil is 20:1 in...

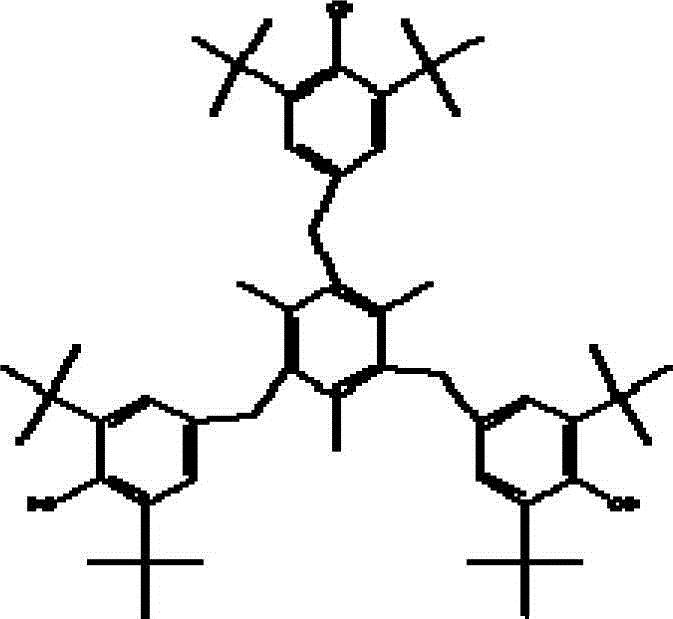

Embodiment 2

[0044] Environmentally friendly neoprene sealant, which includes the following components: neoprene rubber, fillers (including talc, kaolin, magnesium oxide and titanium dioxide), ester solvents (including dimethyl carbonate, ethyl acetate and butyl acetate) , Solvent oil (6# solvent oil and 120# solvent oil), plant extract essential oil (turpentine oil and orange oil), softener (including stearic acid and transformer oil), antioxidant 330.

[0045] Wherein neoprene rubber, filler, ester solvent, mineral spirits, plant extract essential oil, softener, antioxidant 330 weight percentage content are as follows: 16%, 26.9%, 19%, 20%, 10%, 8% %, 0.1%.

[0046] The weight ratio of talcum powder, kaolin, titanium dioxide and magnesium oxide in the filler is 5:20:5:1 in sequence.

[0047] The weight ratio of dimethyl carbonate, ethyl acetate and butyl acetate in the ester solvent is 1:4:5 in sequence.

[0048] The weight ratio of 6# solvent oil and 120# solvent oil in solvent oil is...

Embodiment 3

[0057] Environmentally friendly neoprene sealant, which includes the following components: neoprene rubber, fillers (including talc, kaolin, magnesium oxide and titanium dioxide), ester solvents (including dimethyl carbonate, ethyl acetate and butyl acetate) , solvent oil, plant extract essential oil, softener (including stearic acid, transformer oil), antioxidant 330.

[0058] Wherein neoprene rubber, filler, ester solvent, mineral spirits, plant extract essential oil, softening agent, antioxidant 330 weight percentage content are as follows: 20%, 29.9%, 15%, 19%, 10%, 6 %, 0.1%.

[0059] The weight ratio of talcum powder, kaolin, titanium dioxide and magnesium oxide in the filler is 20:5:5:1 in sequence.

[0060]The weight ratio of dimethyl carbonate, ethyl acetate and butyl acetate in the ester solvent is 1:4:5 in sequence.

[0061] The weight ratio of 6# solvent oil and 120# solvent oil in solvent oil is 20:1 in turn.

[0062] The weight ratio of transformer oil and ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com