Environmentally-friendly low-viscosity SEBS (Styrene-Ethylene-Butadiene-Styrene) spray adhesive and preparation method thereof

An environment-friendly, glue-spraying technology, which is applied in the direction of adhesives, adhesive types, rosin adhesives, etc., can solve problems such as low bonding strength, unsatisfactory aging/heat resistance indicators, and poor environmental protection performance. Convenient construction, good temperature resistance and aging resistance, low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

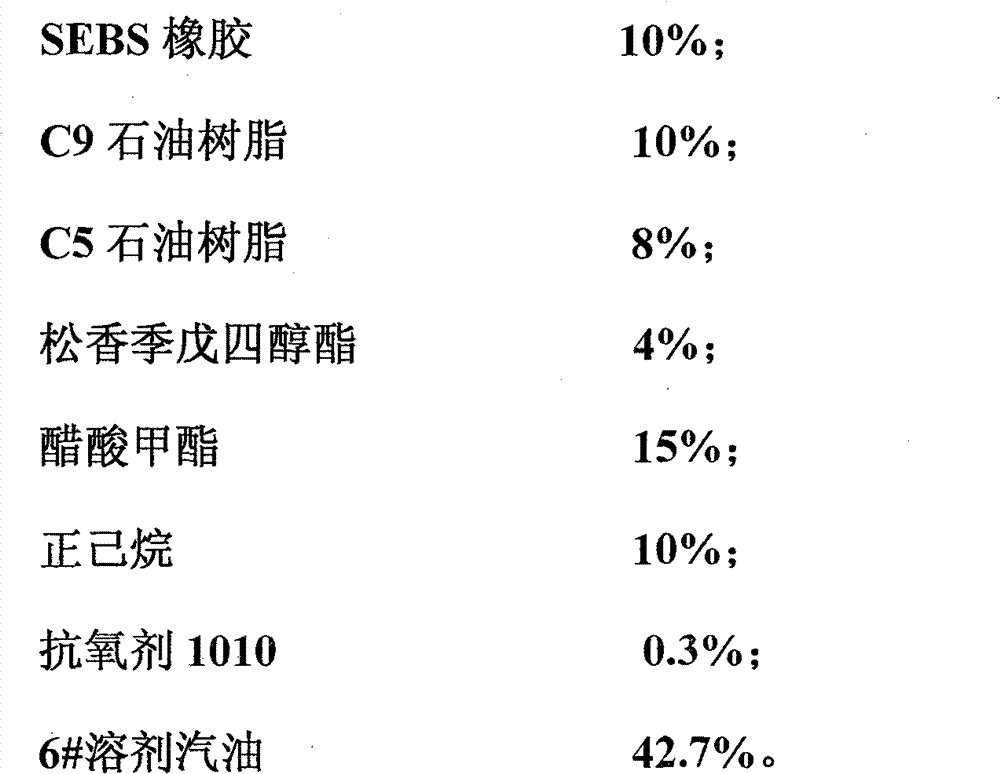

[0031] Environmentally friendly low-viscosity SEBS spray glue, which includes the following components:

[0032] SEBS rubber 10%

[0033] C9 petroleum resin 10%

[0034] C5 petroleum resin 8%

[0035] Rosin pentaerythritol ester 4%

[0036] Methyl acetate 15%

[0037] n-Hexane 10%

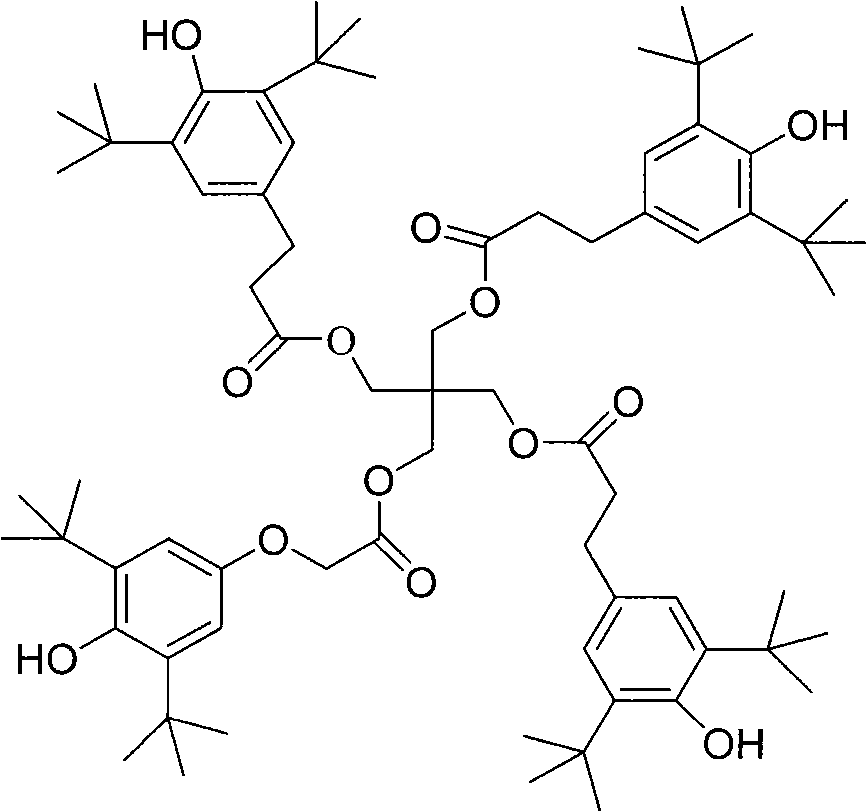

[0038] Antioxidant 1010 0.3%

[0039] 6# solvent gasoline 42.7%

[0040] Above-mentioned formula makes SEBS spray glue of the present invention by following method:

[0041] a. First put quantitative 6# solvent gasoline, ester solvent (methyl acetate) and alkane solvent (n-hexane) into the agitator, and start the machine to stir evenly;

[0042] b, then put the SEBS rubber into the reactor again;

[0043] c. Finally, put the tackifying resin (the mixture containing C9 petroleum resin, C5 petroleum resin and rosin pentaerythritol ester), antioxidant (antioxidant 1010) into the stirrer;

[0044] d. Put all the above materials into the mixer and stir for about 2 hours. After the materials dis...

Embodiment 2

[0051] Environmentally friendly low-viscosity SEBS spray glue, which includes the following components: SEBS rubber: 15%, tackifying resin (including 138 resin, C9 petroleum resin, terpene resin and rosin): 25%, ethyl acetate 8%, Cyclohexane: 5.8%, antioxidant 1010: 0.2%, 6# solvent gasoline: 46%.

[0052] Wherein, the weight ratio of 138 resin, C9 petroleum resin, terpene resin and rosin in the tackifying resin is: 1:2:8:8.

[0053] The preparation method of the above-mentioned environment-friendly low-viscosity SEBS spray glue comprises the following steps in turn: first put quantitative 6# solvent gasoline, ester solvent (ethyl acetate) and alkane solvent (cyclohexane) into the agitator, start the machine to stir uniform; then put SEBS rubber into the reactor again; finally put 138 resin, C9 petroleum resin, terpene resin and rosin in the tackifying resin into the mixer in proportion to stir, and add antioxidant 1010 at the same time; put the above materials Put everything...

Embodiment 3

[0057] Environmentally friendly low-viscosity SEBS spray glue, which includes the following components: SEBS rubber, 138 resin, C9 petroleum resin, C5 petroleum resin, terpene resin, ester solvents (ethyl acetate and ethyl methyl carbonate), alkane solvents ( cyclohexane and n-octane), antioxidant SFH-80 and 6# solvent gasoline. The percentage by weight is as follows: 12%, 9%, 5%, 6%, 3%, 8%, 5%, 0.5% and 51.5%.

[0058] Wherein: the weight ratio of ethyl acetate and ethyl methyl carbonate in the ester solvent is: 1:2. The weight ratio of cyclohexane to n-octane in the alkanes solvent is: 1:2.

[0059]The preparation method is the same as in Example 2. The environmentally friendly low-viscosity SEBS spray glue obtained by this method is a quick-drying adhesive, which is suitable for use in winter or in environments with low temperatures. It can be sprayed on the surface of the adherend with a spray gun in a large area, and it can be bonded after 5 to 10 minutes of drying. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com