SO4<2->/ZrO2-Fe2O3-SiO2 doped mixed-crystal solid acid and preparation method thereof

A technology of zro2-fe2o3-sio2 and solid acid, which is applied in the field of preparation of solid super acid, can solve the problems of limited number of acid centers, failure to reach, low specific surface area of solid acid, etc., to increase the amount of acid centers, easy to share, Good effect with repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

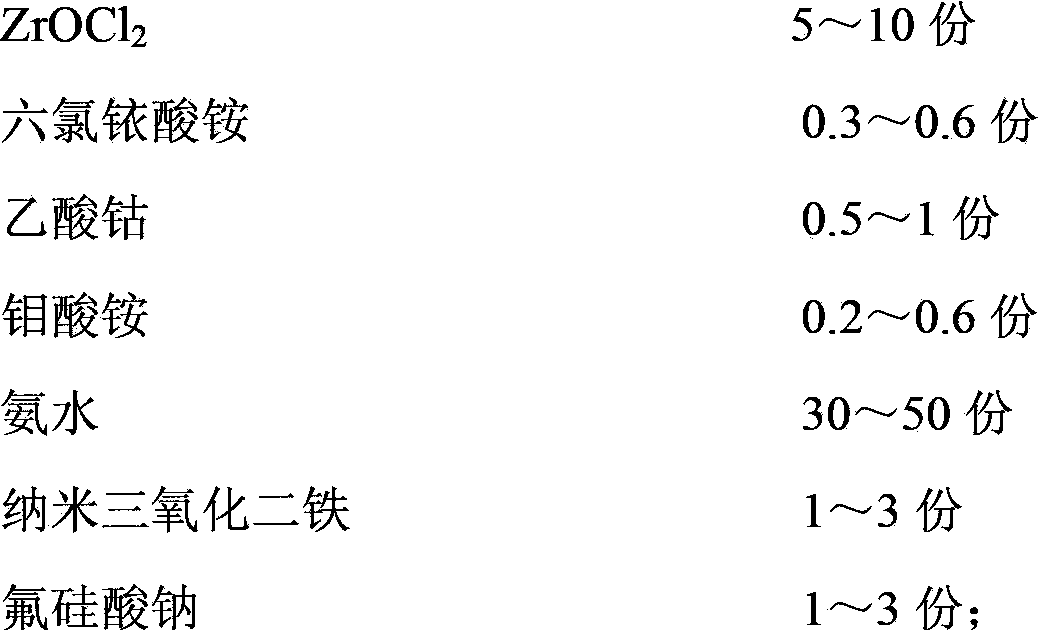

[0016] The mass parts of each component are:

[0017]

[0018] (1) ZrOCl 2 , Ammonium hexachloroiridate, cobalt acetate, and ammonium molybdate are dissolved in the non-ionized water, turn on the high-speed disperser at 1000 rpm, the temperature rises to 85 ℃, drop the ammonia into the solution, the dripping is completed in 30 minutes, immediately Add nano-iron trioxide to the mixed solution, add sodium fluorosilicate after an interval of 1 hour, continue to keep the temperature for 4 hours, then stop the high-speed disperser to stir, reduce to room temperature, stand still for 10 hours, filter the precipitate, each time Wash with 50 parts of ion-free water for 3 times to remove the chloride and fluoride ions in the precipitate, and dry it at 100°C until the water is completely evaporated;

[0019] (2) The product of the process (1) is immersed in 1.67% ammonium chloroplatinate solution for 2 hours, then calcined at 500°C for 4 hours, and then the calcined product is immersed in 5%...

Embodiment 2

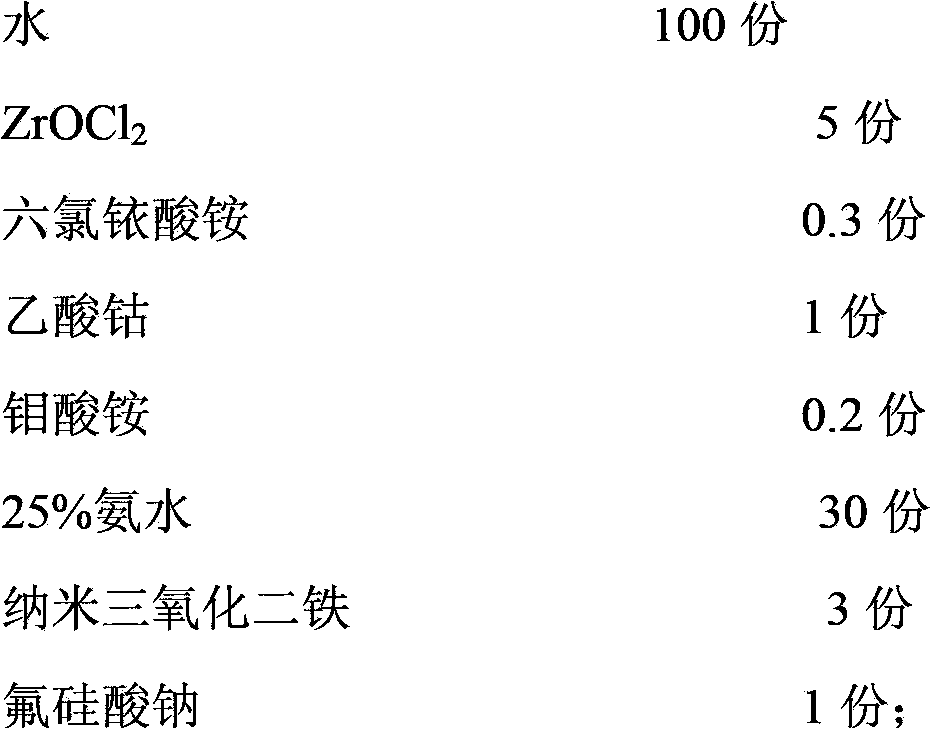

[0021] The mass parts of each component are:

[0022]

[0023] (1) ZrOCl 2 , Ammonium hexachloroiridate, cobalt acetate, and ammonium molybdate are dissolved in deionized water, turn on the high-speed disperser at 1500 rpm, and the temperature rises to 95°C. Add ammonia droplets to the solution. The dripping is completed within 45 minutes, immediately Add nano-iron trioxide to the mixed solution, add sodium fluorosilicate after an interval of 1 hour, continue to keep the temperature for 3 hours, then stop the high-speed disperser to stir, reduce to room temperature, stand still for 5 hours, filter the precipitate, each time Wash 3 times with 50 parts of ion-free water to remove chloride and fluoride ions in the precipitate, and dry at 120°C until all the water evaporates;

[0024] (2) The product of the process (1) is immersed in a 2% ammonium chloroplatinate solution for 3 hours, then calcined at 650°C for 3 hours, and then the calcined product is immersed in a 10% sulfuric acid s...

Embodiment 3

[0026] The mass parts of each component are:

[0027]

[0028]

[0029] (1) ZrOCl 2 , Ammonium hexachloroiridate, cobalt acetate, and ammonium molybdate are dissolved in deionized water, and the high-speed dispersion is turned on at 1300 rpm, the temperature is increased to 90 ℃, and ammonia is added to the solution. The dripping is completed in 40 minutes. Add nano-iron trioxide to the mixed solution, add sodium fluorosilicate after an interval of 1 hour, continue to keep the temperature for 3.5 hours, then stop the high-speed disperser to stir, reduce to room temperature, stand still for 8 hours, filter the precipitate, use each time Wash with 50 parts of non-ionized water for 3 times to remove chloride and fluoride ions in the sediment, and dry at 110°C until all the water evaporates;

[0030] (C) The product of process (b) was immersed in 1% ammonium chloroplatinate solution for 2.5 hours, and then calcined at 580°C for 3.5 hours, and then the calcined product was immersed in 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com