Double-laser beam compound welding device and use method thereof

A beam recombination and welding device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems affecting welding quality, reflectivity drop, material splashing, etc., to solve welding problems, good metallurgical bonding, and realize The effect of metallurgical bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

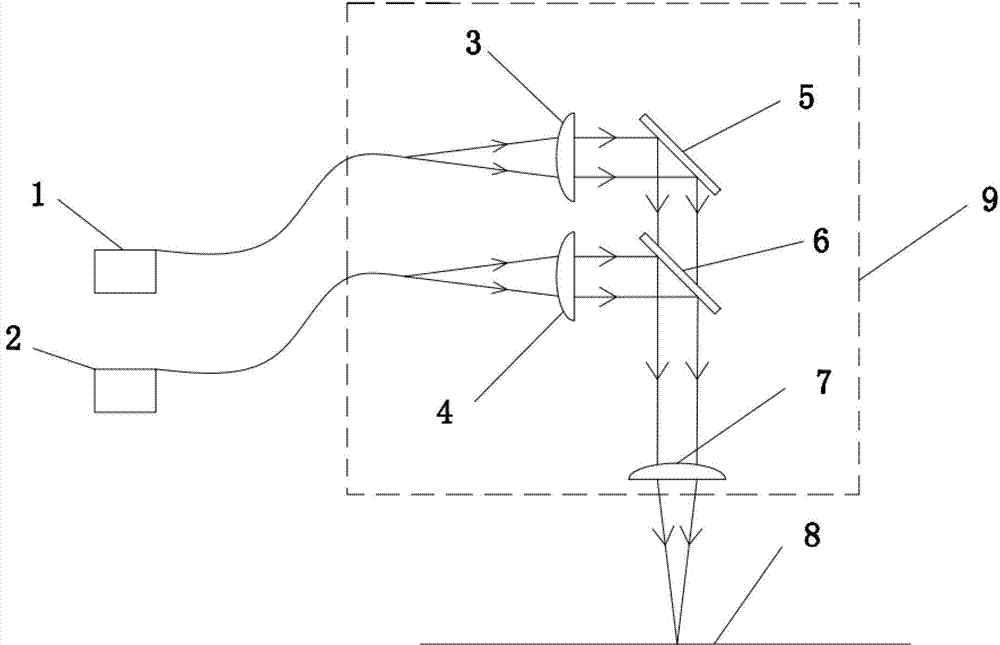

[0010] Attached below figure 1 An embodiment of the present invention is described.

[0011] Double laser beam composite welding device, the device includes a YAG laser transmitter 1, a green laser transmitter 2 and an achromatic welding head 9 with dual flexible optical fiber input and dual beam coaxial output, the optical path of the welding head 9 includes a YAG laser amplifier Through collimating mirror 3, green laser antireflection collimating mirror 4, YAG laser total reflection mirror 5, green laser total reflection and YAG laser enhancement lens 6 and green laser and YAG laser antireflection focusing lens 7, adjust the YAG laser transmission fiber The distance between the fiber head and the front focal point of the YAG laser anti-reflection collimator 3 changes the divergence angle of the YAG laser beam between the YAG laser anti-reflection collimator 3 and the green laser and the YAG laser anti-reflection focusing mirror 7 to change the YAG The position of the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com