Bonding method for micro-fluidic chip based on polymethyl methacrylate (PMMA) and other polymeric materials

A technology of microfluidic chips and polymers, which is applied in the direction of chemical instruments and methods, laboratory containers, laboratory utensils, etc., which can solve the problems of limited applications, the integration of microfluidic chips, and the popularization of miniaturization. problem, achieve the effects of shortened bonding time, easy control of process parameters, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

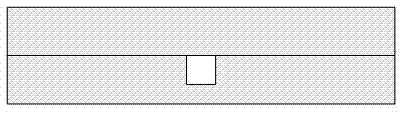

[0025] Specific implementation mode 1: Firstly, two absorbing and heating substrates with flat surfaces are prepared, and the mass ratio of the doped absorbing material is 27%. During preparation, an appropriate amount of substances capable of generating heat under microwave radiation is mixed into the heating substrate material. Align and cover the two substrates of the chip. Place a heated substrate horizontally into a closed container with an electromagnetic wave generator, and then place the microfluidic chip (including the substrate and cover) on the heated substrate. Afterwards, another heating substrate is horizontally covered on the microfluidic chip. After putting the chip and heating substrate into the airtight container, close the container. Wherein, the size of the microchannel on the microfluidic chip is 156 μm×150 μm. The electromagnetic wave power is set to 800W, the timing is 40 seconds, the bonding temperature is controlled within the range of 95-200° C., a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com