Method for recycling high-purity fluorine and phosphorus from wastewater of phosphogypsum residue field

A phosphogypsum, high-purity technology, applied in chemical instruments and methods, phosphorus compounds, water/sewage multi-stage treatment, etc., can solve problems such as large fluctuations in fluoride ions, large amounts of sludge, waste of resources, etc., and achieve phosphorus recovery rate High, high recovery rate, the effect of realizing resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

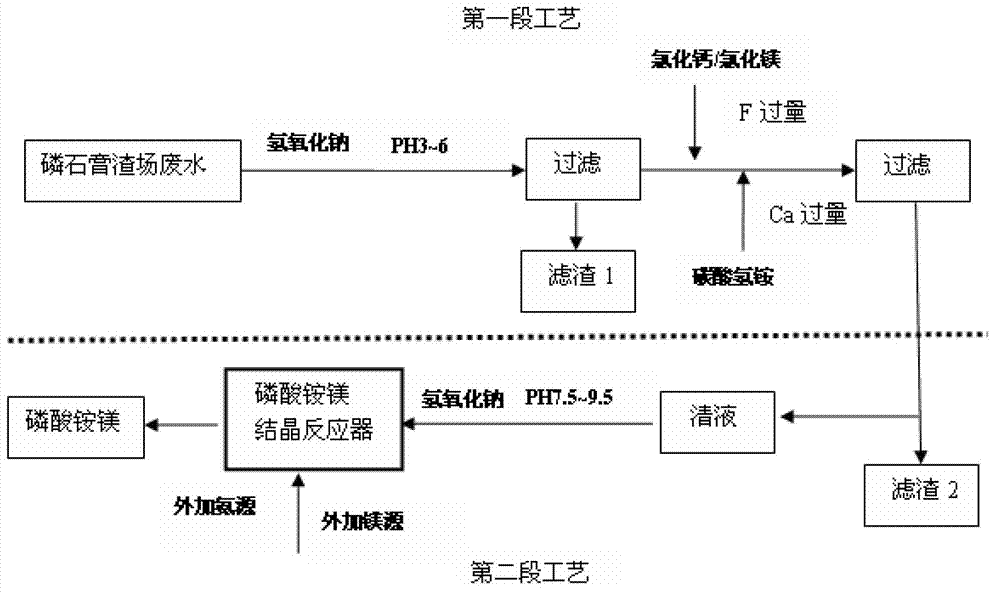

Method used

Image

Examples

Embodiment 1

[0025] The wastewater discharge volume of a phosphogypsum slag yard in a chemical plant is 5000m3 / d, of which the phosphorus content in the wastewater is 5200mg / l, the fluorine content is 1500mg / l, the calcium ion content is 2300mg / l, and the pH of the wastewater is 2.3; the molar concentration of the first stage process is 1mol / l sodium hydroxide solution to adjust the pH of wastewater from the phosphogypsum slag field to 5.3, with calcium fluoride precipitation and a small amount of calcium phosphate precipitation formed. After analysis, the purity of calcium fluoride is 95%, and the recovery rate of fluorine is 99%. Among them, the residual fluorine in the wastewater Phosphorus is 15mg / l, phosphorus is 4698mg / l, calcium is 20mg / l; the second stage process uses sodium hydroxide solution with a molar concentration of 1mol / l to adjust the pH of phosphogypsum slag field wastewater to pH8.2, and the added concentration is 1mol / l chlorination 750ml of ammonium solution and 780ml ...

Embodiment 2

[0027] The wastewater discharge of a phosphogypsum slag yard in a chemical plant is 5000m3 / d, of which the phosphorus content in the wastewater is 10000mg / l, the fluorine content is 500mg / l, the calcium ion content is 1300mg / l, and the pH of the wastewater is 1.0; the molar concentration of the first stage process is 1mol / l sodium hydroxide solution to adjust the pH of phosphogypsum slag field wastewater to 3.0, calcium fluoride precipitation and a small amount of calcium phosphate precipitation are formed, the purity of calcium fluoride is 96% after analysis, the recovery rate of fluorine is 98%, and the residual fluorine in the wastewater 10mg / l, 9200mg / l phosphorus, and 15mg / l calcium; the second stage of the process uses a sodium hydroxide solution with a molar concentration of 1mol / l to adjust the pH of the phosphogypsum slag field wastewater to pH7.5, and the added concentration is 2mol / l bicarbonate 740ml of ammonium solution and 780ml of magnesium chloride solution wit...

Embodiment 3

[0029] The wastewater discharge volume of a phosphogypsum slag yard in a chemical plant is 5000m3 / d, of which the phosphorus content in the wastewater is 7000mg / l, the fluorine content is 3500mg / l, the calcium ion content is 6000mg / l, and the pH of the wastewater is 3.0; the molar concentration of the first stage process is 1mol / l sodium hydroxide solution to adjust the pH of wastewater from phosphogypsum slag field to 6.0, calcium fluoride precipitation and a small amount of calcium phosphate precipitation are formed, the purity of calcium fluoride is 99% after analysis, the recovery rate of fluorine is 99.7%, and the residual fluorine in the wastewater It is 15mg / l, phosphorus is 5800mg / l, and calcium is 25mg / l. After the treatment, an appropriate amount of ammonium bicarbonate is added to remove calcium ions, and the introduction of ammonium ions can participate in the second stage of the reaction of ammonium magnesium phosphate; The molar concentration is 1mol / l sodium hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com