Additive of electrolytic acidic cupric chloride solution

A copper chloride and additive technology, which is applied in the electrolysis process, electrolysis components, photography process and other directions, can solve the problems of high impurity content and low purity of cathode copper, and achieve the effects of improving purity, simple preparation and enhancing cathode polarization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The electrolytic acid copper chloride additive in the present embodiment one, its component and mass percent content are as follows:

[0014] Propylene glycol polyether: 4%

[0015] Dimethyl-p-phenylenediamine: 2%

[0016] Sodium dodecyl sulfonate: 2%

[0017] Water: 92%

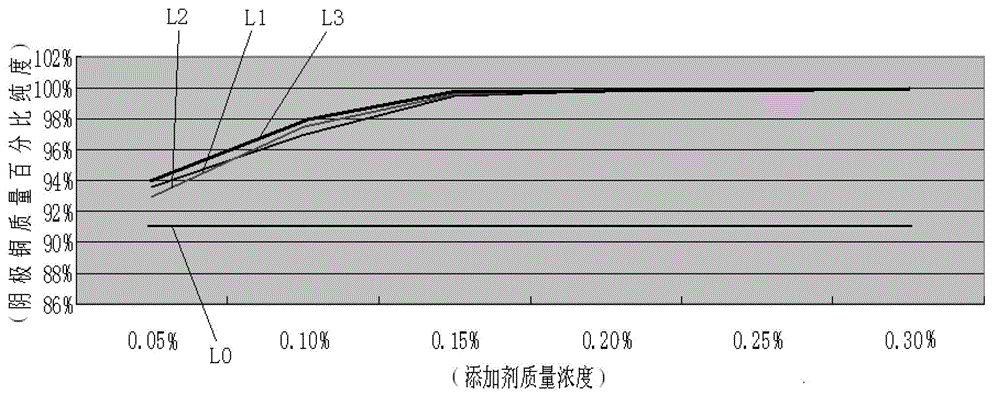

[0018] According to the above ratio configuration, the above additives are added to Cu by mass percentage 0.05~0.3% 2+ Content 50g / L, Cl - Content 180g / L, H + In an acidic copper chloride solution with a concentration of 2mol / L, the temperature is controlled at 35°C, and the current density is 4A / dm 2 After 48 hours of electrolysis, take the cathode copper and dry it to measure the purity of the cathode copper. For details, please refer to the attached figure 1 Middle L1.

Embodiment 2

[0020] In the present embodiment two, electrolytic acid copper chloride additive, its component and mass percent content are as follows:

[0021] Polyethylene glycol ether: 3%

[0022] Hexamethylenediamine: 2%

[0023] Alkyl dipropyl ether disulfonate: 3%

[0024] Water: 92%

[0025] According to the above ratio configuration, the above additives are added to Cu by mass percentage 0.05~0.3% 2+ Content 50g / L, Cl ― Content 180g / L, H + In an acidic copper chloride solution with a concentration of 2mol / L, the temperature is controlled at 35°C, and the current density is 4A / dm 2 After 48 hours of electrolysis, take the cathode copper and dry it to measure the purity of the cathode copper. For details, please refer to the attached figure 1 Middle L2.

Embodiment 3

[0027] The electrolytic acid copper chloride additive of present embodiment three, its component and mass percent content are as follows:

[0028] Allyl alcohol polyoxyalkyl ether: 5%

[0029] Cyclohexylamine: 3%

[0030] Sodium dodecyl sulfonate: 2%

[0031] Water: 90%

[0032] According to the above ratio configuration, the above additives are added to Cu by mass percentage 0.05~0.3% 2+ Content 50g / L, Cl - Content 180g / L, H + In an acidic copper chloride solution with a concentration of 2mol / L, the temperature is controlled at 35°C, and the current density is 4A / dm 2 After 48 hours of electrolysis, take the cathode copper and dry it to measure the purity of the cathode copper. For details, please refer to the attached figure 1 Middle L3.

[0033] Please refer to the attached figure 1 , among the figure L0, L1, L2, L3 correspond to three kinds of cathode copper purity in not adding the additive of the present invention, embodiment one, embodiment two, embodiment three...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com