Covering-type copper-nickel-silver composite powder and preparation method thereof

A composite powder, copper-nickel-silver technology, applied in coatings and other directions, can solve problems such as industrial production limitations, complex preparation processes, raw material pollution, etc., and achieve the effects of good interface bonding, simple process and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

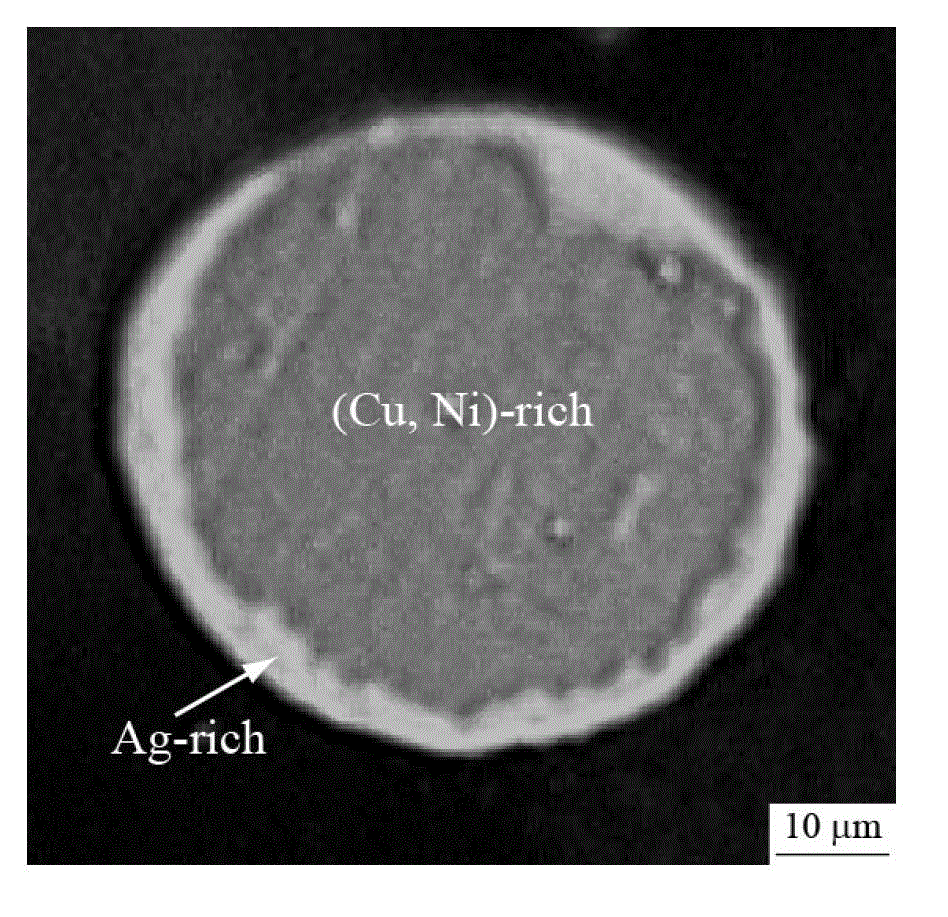

[0014] Design the composition of wrapped copper-nickel-silver composite alloy powder according to the binary or multi-component phase diagram; 100g pure copper (electrolytic copper, purity 99.9wt.%), 400g pure nickel (purity 99.99wt.%), 500g pure Silver (purity: 99.99wt.%) is placed in an alumina crucible, and then the alumina crucible is placed in a vacuum induction furnace built into the atomization equipment (power supply voltage: 110V / 220VAC; power supply frequency: 50-60Hz; working Frequency: 150 ~ 250KHz), close the furnace door and then evacuate until the vacuum in the vacuum induction furnace reaches 1×10 -3 Pa, increase the current until the above three pure metals are completely melted to liquid, and the liquid composition of the obtained alloy is 10Cu-40Ni-50Ag (wt.%). Pour the molten alloy liquid (about 1kg) into the liquid receiving hopper, and blow it with argon flow at the moment the liquid flows into the atomization chamber, and the copper-nickel-silver alloy p...

Embodiment 2

[0017] Place 100g of pure copper (electrolytic copper, with a purity of 99.9wt.%), 500g of pure nickel (with a purity of 99.99wt.%), and 400g of pure silver (with a purity of 99.99wt.%) in an alumina crucible, according to the example Step operation described in 1, the copper-nickel-silver alloy powder of preparation gained, its cross-sectional structure diagram and figure 1 Similarly, it is a wrapped structure, the core is a copper-nickel alloy ((Cu,Ni)-rich) core, and the outer shell is a silver alloy (Ag-rich) shell.

Embodiment 3

[0019] Place 400g of pure copper (electrolytic copper, with a purity of 99.9wt.%), 400g of pure nickel (with a purity of 99.99wt.%), and 200g of pure silver (with a purity of 99.99wt.%) in an alumina crucible, according to the example Step operation described in 1, the copper-nickel-silver alloy powder of preparation gained, its cross-sectional structure diagram and figure 1 Similarly, it is a wrapped structure, the core is a copper-nickel alloy ((Cu,Ni)-rich) core, and the outer shell is a silver alloy (Ag-rich) shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com