Composite heat insulation material using phenolic resin and perlite as major raw materials and preparation method of composite heat insulation material

A technology of composite thermal insulation material and phenolic resin, which is applied in the field of thermal insulation material and its preparation, can solve the problems of organic thermal insulation materials such as aging resistance, toxic gas discharge, and small thermal conductivity, and achieve small deformation coefficient, good fire resistance, The effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

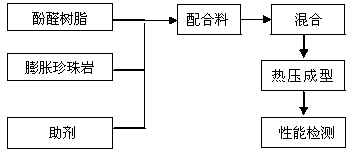

[0030] Its specific preparation method steps are as follows:

[0031] (1) Grind the solid phenolic resin to 80~100 mesh or choose powdery resin directly, and choose a bulk density of 80~150 kg / m 3 Spherical closed-cell expanded perlite bulk;

[0032] (2) According to the mass fraction of resin 20~70%, expanded perlite 30~80%, auxiliary agent 5~10% to prepare raw materials;

[0033] (3) Fully mix the raw materials in step (2) evenly, and put them into a steel mold;

[0034] (4) Under the conditions of compression ratio of 1.25-2.5 and hot-pressing temperature of 200-240°C, hot-pressing and holding pressure for 1.5-2.5 hours, a composite insulation material with phenolic resin and perlite as the main raw materials can be obtained.

Embodiment 1

[0036] (1) Grind the solid boron-modified phenolic resin to 80-100 mesh; choose a bulk density of 80-150 kg / m 3 Spherical closed-cell expanded perlite bulk; choose silicone water repellent, hexamethylenetetramine curing agent, zinc stearate lubricant, and nitrile rubber toughening agent.

[0037] (2) According to the mass fraction of resin 40%, expanded perlite 50%, additives 10% (including 1% water-repellent agent, 7% curing agent, 1% lubricant, 1% toughening agent) to prepare raw materials.

[0038] (3) Mix the raw materials thoroughly and evenly, and put them into steel molds.

[0039] (4) Under the condition of compression ratio of 1.67 and hot pressing temperature of 220 °C, hot pressing was performed, and the pressure was maintained for 2 hours to obtain a phenolic resin / perlite composite insulation material.

[0040] The obtained phenolic resin / perlite composite insulation material sample has an apparent density of 290 Kg / m 3 , thermal conductivity 0.042 W / (m﹐K), comp...

Embodiment 2

[0042] (1) Grind the solid boron-modified phenolic resin to 80-100 mesh; choose a bulk density of 80-150 kg / m 3 Spherical closed-cell expanded perlite bulk; choose silicone water repellent, hexamethylenetetramine curing agent, zinc stearate lubricant, and nitrile rubber toughening agent.

[0043] (2) According to the mass fraction of resin 40%, expanded perlite 50%, additives 10% (including 1% water-repellent agent, 7% curing agent, 1% lubricant, 1% toughening agent) to prepare raw materials.

[0044] (3) Mix the raw materials thoroughly and evenly, and put them into steel molds.

[0045] (4) Under the conditions of compression ratio of 2 and hot pressing temperature of 220 °C, hot pressing was performed, and the pressure was maintained for 2 hours to obtain a phenolic resin / perlite composite insulation material.

[0046] The obtained phenolic resin / perlite composite insulation material sample has an apparent density of 320 Kg / m 3 , thermal conductivity 0.048 W / (m﹐K), compre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com