A kind of repair method of aluminum and aluminum alloy welding seam

A technology for aluminum alloys and weldments, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of aluminum and aluminum alloy welding repair headaches, welding seam forming difficulties, welding defects increase, etc., to improve the repair work efficiency , The method is simple, the effect of reducing the repair cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

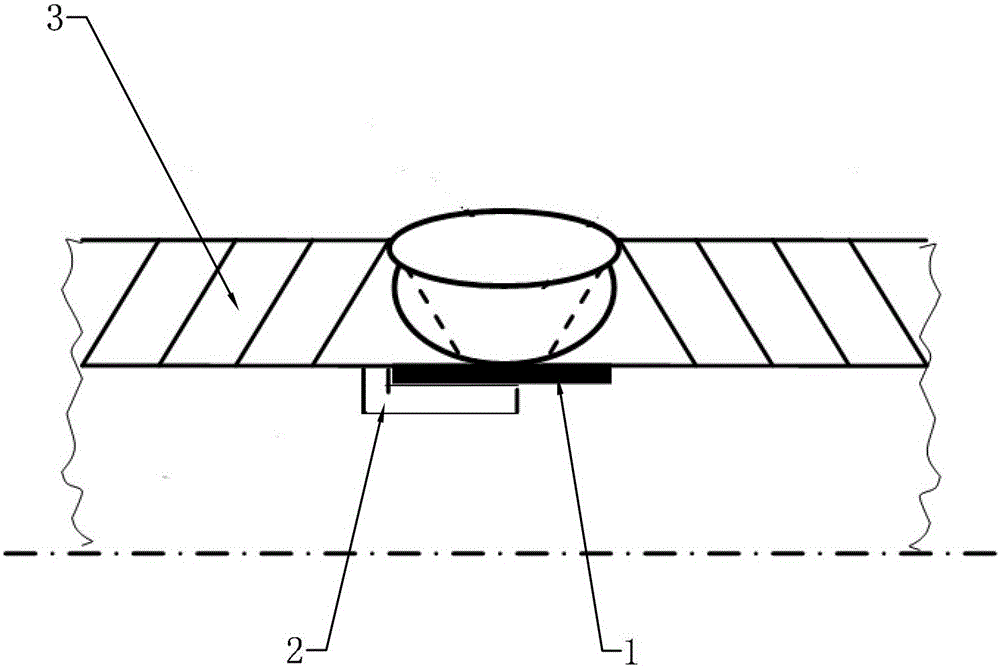

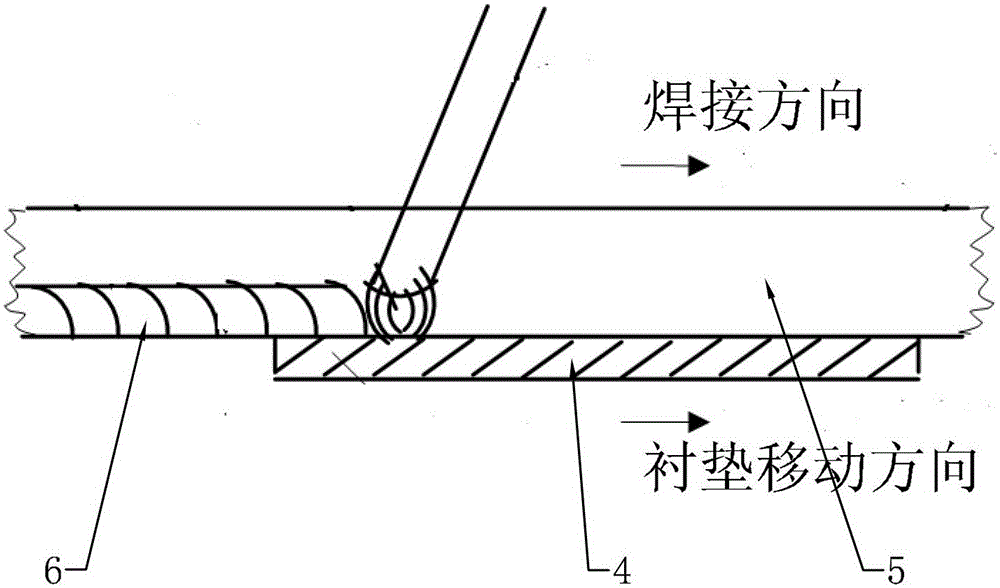

[0023] A method for repairing aluminum and aluminum alloy welds according to the invention is mainly used for repairing welding defects, especially for repairing deep-buried welding defects that are deeply buried in the root of the weld or close to 1 / 2 of the root. This method takes advantage of the soft and easy-to-cut characteristics of aluminum and aluminum alloy materials, and uses tools such as disc alloy blades to grind and remove the weld seams at welding defects to form penetrating openings. Repair welding is completed by welding.

[0024] Its specific operation process is:

[0025] 1) Determine the position of the welding defect at the weld of the weldment, form a penetrating opening at the defect position, set a groove on the opening, the groove gap is less than or equal to 8 mm, and the groove is located on the outer wall of the weldment.

[0026] (1) Determine the length of the weld seam for one-time repair (one-time opening length), the length should not be less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com