Organosilicone modified heat-resistant self-cleaning waterborne electrochemistry corrosion-resistant paint and preparation method thereof

A high-temperature, self-cleaning technology, used in anti-corrosion coatings, coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

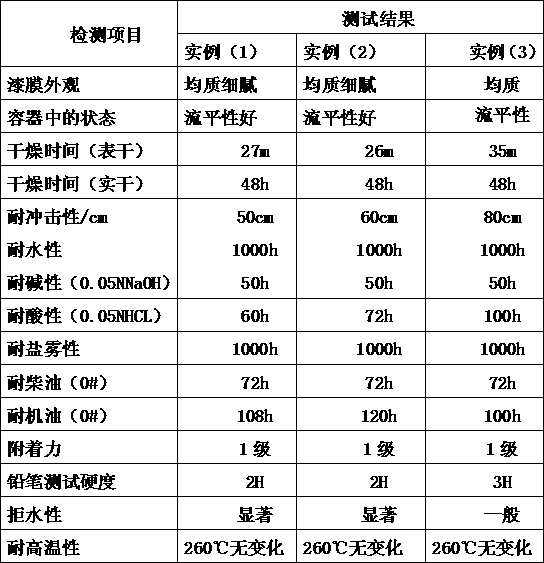

Examples

preparation example (1)

[0036] Take 230g of deionized water, PH adjuster AMP-951g, ammonium salt dispersant 1.7g, sodium salt dispersant 5g, wetting agent PE-1001g, ethylene glycol 5g, film forming aid lauryl ester 18g, defoamer NXZ1g , 130g of pretreated titanium dioxide, 80g of pretreated kaolin, 30g of pretreated barium sulfate, 47g of modified aluminum phosphate, 47g of zinc phosphate, 50g of pretreated mica powder, leveling agent RM-20203.3g, Put the above-mentioned raw materials into a high-speed dispersing kettle in turn, disperse at a high speed for 1 hour, feed them to the paint mixing kettle, add 500g of MPM modified emulsion, 1g defoamer NXZ, 35g deionized water, under low-speed stirring, add X-405 (dispersing wetting agent) ) 2g, 5g anti-flash rust agent, 3g of preferred silane coupling agent γ-methacryloxytrimethoxysilane, 3g of antiseptic bactericide, alkali swelling and polyurethane thickener to adjust viscosity When it reaches the appropriate value, filter and package to obtain white w...

preparation example (2)

[0038] Take 230g deionized water, PH adjuster AMP-951g, ammonium salt dispersant 1.7g, sodium salt dispersant 5g, wetting agent (PE-100) 1g, ethylene glycol 5g, film-forming assistant lauryl ester 18g, Foaming agent NXZ1g, pretreated titanium dioxide 150g, pretreated barium sulfate 80g, modified aluminum phosphate 50g, zinc phosphate 40g, pretreated mica powder 60g, medium yellow 10g, pretreated kaolin 50g, bright red 10g, leveling agent (RM-2020) 3g, put the above-mentioned raw materials into the high-speed dispersing kettle in turn, disperse at high speed for 1h, feed to the paint mixing kettle, add 550g MPM modified emulsion, 1g defoamer NXZ, 35g deionized water, Under low-speed stirring, add 2g of X-405 (dispersing wetting agent), 5g of anti-flash rust agent, and 3.3g of preferred silane coupling agent γ-methacryloxytrimethoxysilane, 3g of antiseptic and bactericide, and alkali Swelling and polyurethane thickeners each adjust the viscosity to a suitable value, filter and pa...

preparation example (3)

[0040] Take 300g of deionized water, 1g of PH adjuster (AMP-95), 2.2g of ammonium salt dispersant, 4.8g of sodium salt dispersant, 1g of wetting agent (PE-100), 5g of ethylene glycol, and dodecyl alcohol as a film forming aid Grease 19g, defoamer NXZ1g, pretreated titanium dioxide 110g, phosphorus iron powder 130g, pretreated kaolin 60g, modified aluminum phosphate 50g, zinc phosphate 40g, carbon black 5g, leveling agent (RM-2020) 3g, put the above-mentioned raw materials into a high-speed dispersing kettle in turn, disperse at a high speed for 1h, feed them to the paint mixing kettle, add 530g MPM modified emulsion, 1g defoamer NXZ, 50g deionized water, under low-speed stirring, put in X-405 (dispersion Wetting agent) 2g, anti-flash rust agent 4.7g, preferred silane coupling agent γ-methacryloxytrimethoxysilane 2.9g, adding antiseptic fungicide 3g, adding alkali swelling and polyurethane thickener Adjust the viscosity to an appropriate value by appropriate amount, filter and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com