Silk-fibroi and hyaluronic-acid (HA) composite gel for injection and preparation and application thereof

A composite gel and silk fibroin technology, which is applied in medical science, surgery, etc., can solve the problems of poor water absorption and low hyaluronic acid content of the composite gel, and achieve improved resistance to enzymolysis in vitro, small inflammatory reactions, and improved The effect of lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Silk fibroin hyaluronic acid composite gel

[0036] (1) Preparation of silk fibroin microspheres: Add 40g of silkworm silk to 2700ml of 0.2% sodium carbonate aqueous solution, bathe in water at 96-100°C for 60 minutes, filter, take the filter cake and repeat the water bath for 3 times, and take the last filtered After drying the filter cake at 60°C, dissolve it slowly with 200ml of 9mol / L lithium bromide aqueous solution, put it in a water bath at 60°C for 6h, then centrifuge at 8000rpm for 5min, take the supernatant, and put the centrifuged supernatant into a dialysis bag (MW8,000 ~14,000), with purified water as the dialysate, magnetic stirring and dialysis for three days, the retentate was taken, and a silk fibroin solution with a mass concentration of 5% was prepared with purified water.

[0037] At 25°C, let the above 5% silk fibroin solution stand still to form 5g of white gel material, homogenize the gel material with a homogenizer (T25, IKA) at 240...

Embodiment 2

[0040] Embodiment 2 silk fibroin hyaluronic acid composite gel

[0041] (1) According to the method described in step (1) of Example 1, 3.5 g of silk fibroin particles passed through a 200-mesh sieve were prepared, with a mass concentration of 3.23%.

[0042] (2) Dissolve 0.7g sodium hyaluronate in 7ml mass concentration of 1% sodium hydroxide solution to make 0.1g / ml sodium hyaluronate solution, and add the silk fibroin obtained in step (1) to the hyaluronic acid solution Protein particles 1.0836g (0.035 / 0.0323=1.0836g), mixed well, added 56μl BDDE, mixed evenly, placed at 40°C for 6 hours for cross-linking, forming silk fibroin hyaluronic acid composite gel material .

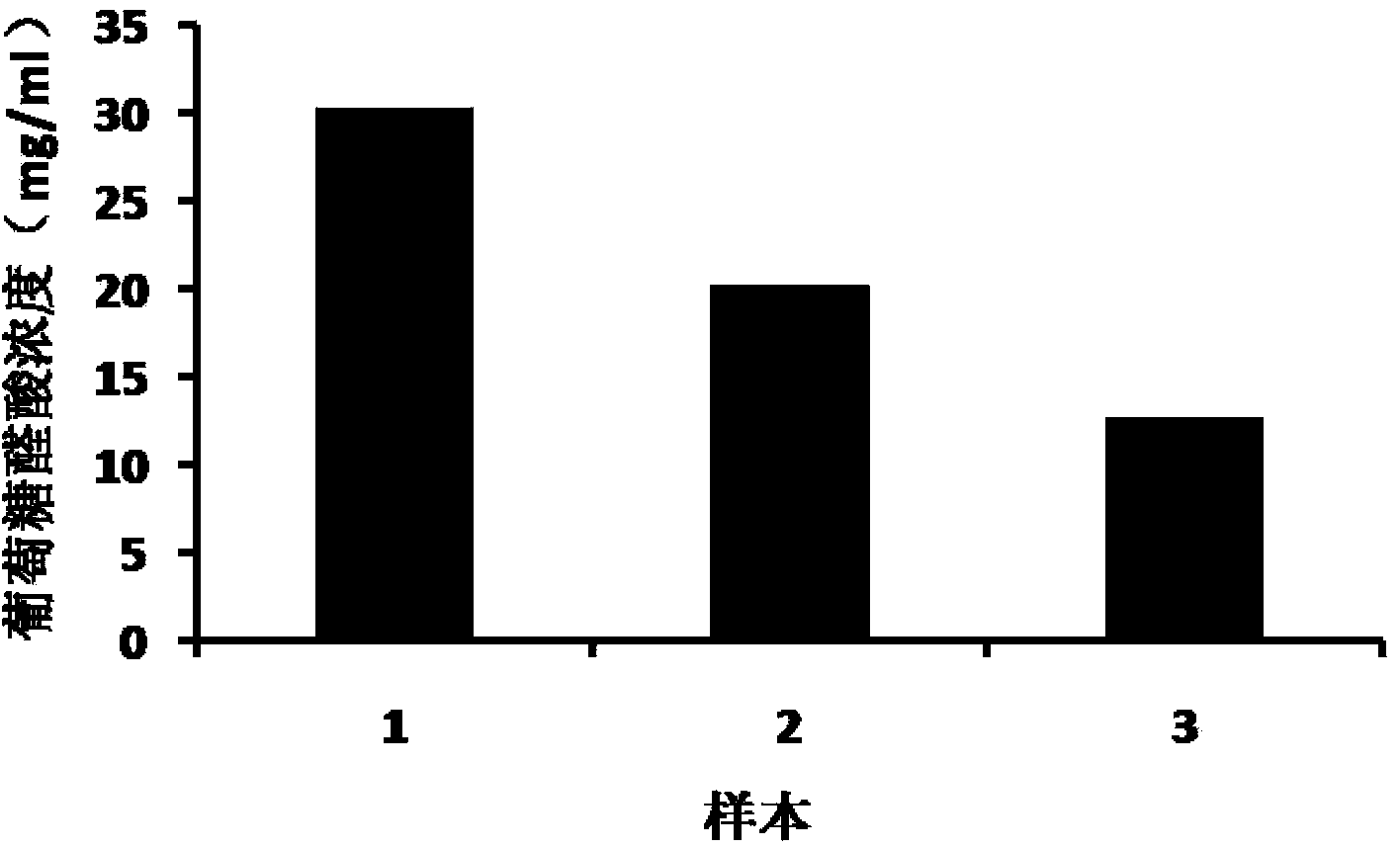

[0043] The above-mentioned silk fibroin hyaluronic acid composite gel material was subjected to dialysis treatment, and other operations were the same as in Example 1 to obtain 35 g of silk fibroin hyaluronic acid composite gel for injection, which can be used as a tissue filling injection product. Take the...

Embodiment 3

[0044] Embodiment 3: silk fibroin hyaluronic acid composite gel

[0045] (1) According to the method described in step (1) of Example 1, 3.5 g of silk fibroin particles passed through a 200-mesh sieve were prepared, with a mass concentration of 3.23%.

[0046] (2) Dissolve 0.7g sodium hyaluronate in 7ml mass concentration of 1% sodium hydroxide solution to make 0.1g / ml sodium hyaluronate solution, and add 2.167g (0.07 / 0.0323 =2.167g) of silk fibroin particles, mixed well, added 56 μl of BDDE, mixed evenly, and placed at 40°C for 5 hours for cross-linking to form a silk fibroin hyaluronic acid composite gel material.

[0047] The silk fibroin hyaluronic acid composite gel material was subjected to dialysis treatment, and other operations were the same as in Example 1 to obtain 35 g of silk fibroin hyaluronic acid composite gel for injection, which can be used as a subcutaneous filling injection product. Take the silk fibroin hyaluronic acid composite gel and dilute it with dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com