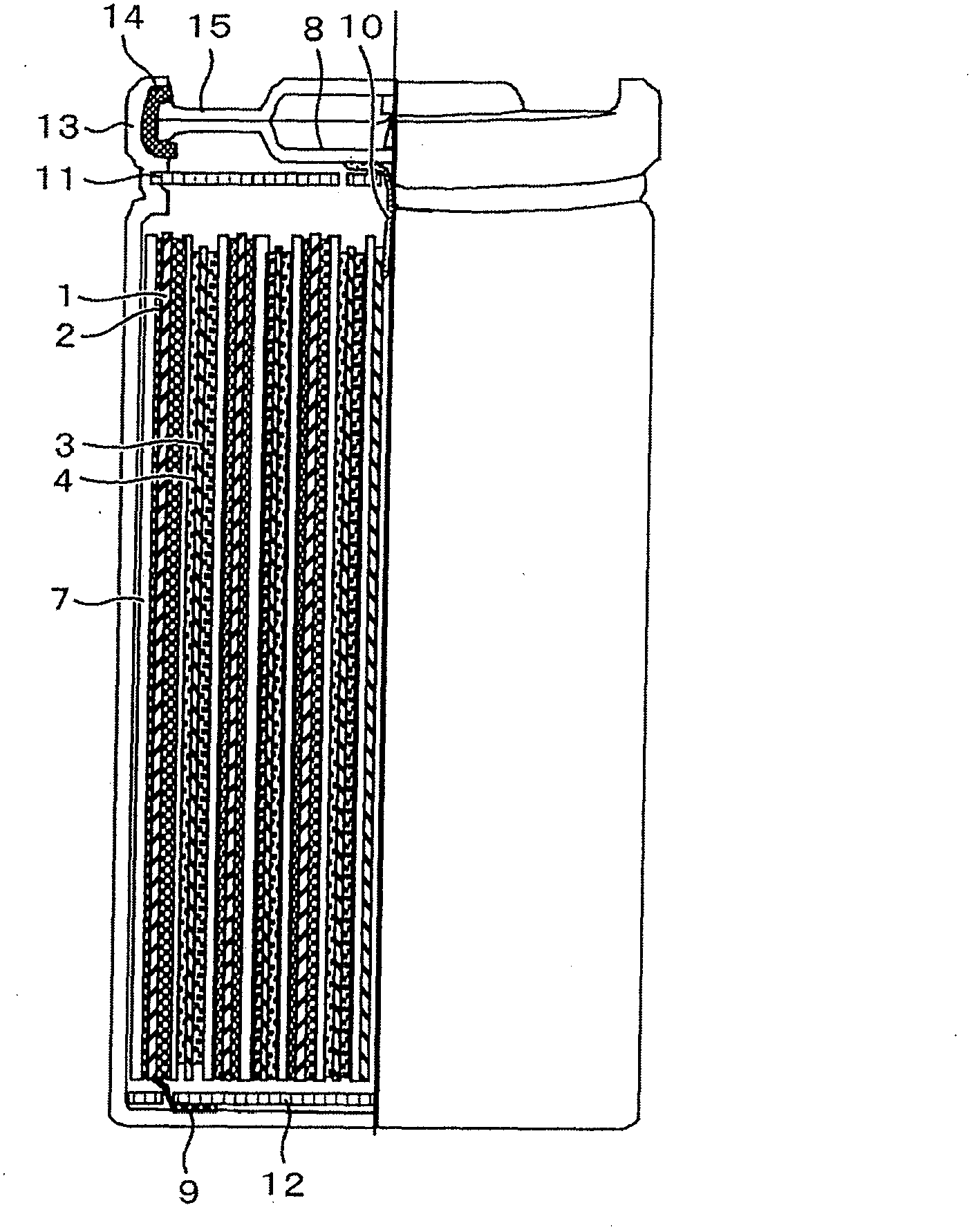

Lithium ion secondary battery

A secondary battery, lithium ion technology, used in secondary batteries, battery electrodes, battery pack components, etc., can solve problems such as insufficient and reduced output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

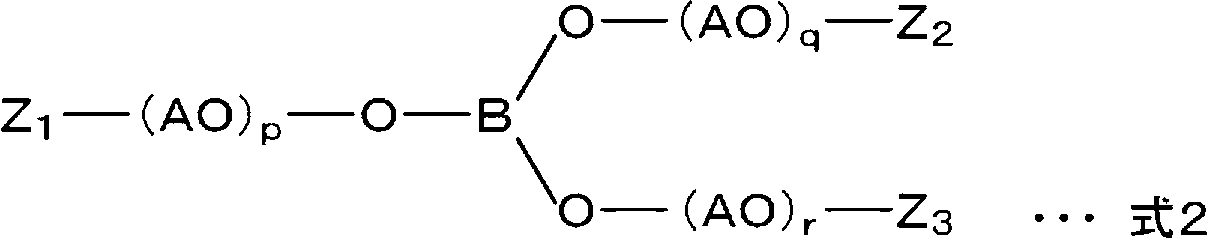

Method used

Image

Examples

Embodiment 1

[0104] (Production of coated negative electrode active material)

[0105] Disperse 10 parts by weight of amorphous carbon, that is, pseudo anisotropic carbon as a negative electrode active material, in 90 parts by weight of an acetonitrile solution containing 1 wt% of polyethylene carbonate (PEC) (number average molecular weight: 50,000). The resulting dispersion was left in an organic draft for 6 hours. Then, the negative electrode active material was precipitated in the dispersion, and 70 parts by weight of the supernatant was removed. Then, the remaining precipitate was dried in an atmosphere of 80° C. for 12 hours to obtain a negative electrode active material with almost no aggregation. The existence of the PEC coated on the negative electrode active material can be confirmed by observing the characteristic stretching vibration of the functional group contained in the PEC by measuring the diffuse reflectance infrared absorption spectrum. In this example, especially the ...

Embodiment 2

[0123] (Production of coated negative electrode active material)

[0124] Disperse 10 parts by weight of amorphous carbon, that is, pseudo anisotropic carbon as a negative electrode active material, in 90 parts by weight of an acetonitrile solution containing 1 wt% of polyethylene carbonate (PEC) (number average molecular weight: 50,000). The resulting dispersion was placed in an organic ventilator for 6 hours. Then, the negative electrode active material was precipitated in the dispersion, and 70 parts by weight of the supernatant was removed. Then, the remaining precipitate was dried in an atmosphere of 80° C. for 12 hours to obtain a PEC-coated negative electrode active material with almost no aggregation. Furthermore, the PEC-coated negative electrode active material was dispersed in dicarbonate containing 5 wt% of vinylene carbonate (VC) and 0.1 wt% of 2,2'-azobisisobutyronitrile (AIBN) as a radical polymerization initiator. in methyl ester solution. The resulting disp...

Embodiment 3

[0126] (Production of coated negative electrode active material)

[0127] With respect to 100 parts by weight of amorphous carbon, that is, pseudo anisotropic carbon as the negative electrode active material, an amount equivalent to 1 part by weight of vinyltriethoxysilane was previously dispersed in pure water so as to have a concentration of 10% by weight. The resulting solution was fully mixed, and then vacuum-dried at 150° C. for 2 hours to obtain a silane-treated negative electrode active material. Next, 10 parts by weight of the silane-treated negative electrode active material was dispersed in 90 parts by weight of an acetonitrile solution having a polyethylene carbonate (PEC) content of 1 wt%. The resulting dispersion was placed in an organic ventilator for 6 hours. Then, the negative electrode active material was precipitated in the dispersion, and 70 parts by weight of the supernatant was removed. Then, the remaining precipitate was dried in an atmosphere of 80° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com