High-entropy alloy powder used for spraying

A high-entropy alloy and powder technology, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the problems that the coating forming quality and surface continuity cannot meet the production and use requirements, so as to improve the spraying effect, Effect of improving self-fluxing property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

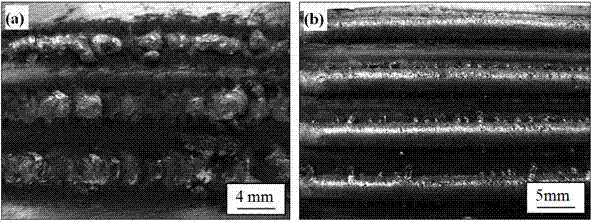

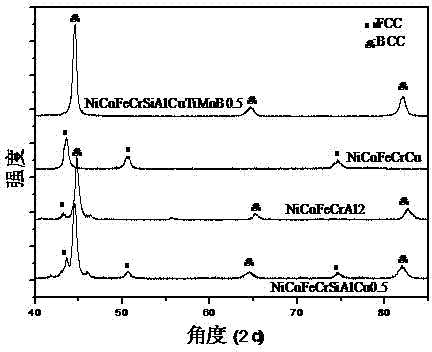

[0016] CuCoNiCrFe high entropy alloy coating preparation:

[0017] The high-entropy alloy powder of CuCoNiCrFe was prepared according to the molar percentage, and the powder configuration of pure metal elements was used. The addition content of the five main elements was 19.6%, and B: 1%, Si: 1%. The configured elements are uniformly mixed in CO 2 Under the irradiation of high-power laser, the surface of Q235 substrate material was clad in a single pass by synchronous powder feeding method. The laser power used was 2.0 kW, the scanning speed was 100 mm / min, and an inert gas was used to protect it during cladding.

Embodiment 2

[0019] NiCoFeCrAl 2 High entropy alloy coating preparation:

[0020] Preparation of NiCoFeCrAl by mole percentage 2 The high-entropy alloy powder is made of pure metal element powder, in which Ni, Co, Fe, and Cr are all added at 16%, Al at 32%, and B and Si at 2%. The configured elements are uniformly mixed in CO 2 Under the irradiation of high-power laser, the surface of Q235 substrate material was clad on the surface of Q235 base material by synchronous powder feeding method. The laser power used was 3.5 kW, the scanning speed was 500 mm / min, and the cladding was protected by inert gas.

Embodiment 3

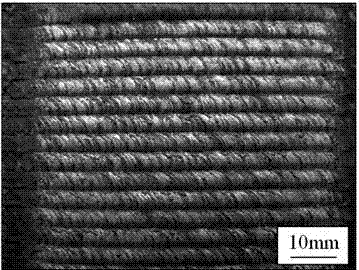

[0022] NiCoFeCrSiAlCu 0.5 High entropy alloy coating preparation:

[0023] Preparation of NiCoFeCrSiAlCu by Mole Percentage 0.5 High-entropy alloy powder, in which Ni, Co, Fe, Cr, Si, and Al are all added at 15%, Cu is 7.5%, and B: 2.5% is added. After being smelted into a bulk alloy in a vacuum electric arc furnace, the mechanical Grinding method to prepare the desired powder. in CO 2 Under high-power laser irradiation, multi-pass cladding on the surface of the Q235 base material was carried out by synchronous powder feeding. Inert gas protection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com